Novel sewage treatment process utilizing ferrate oxidization to reduce sludge quantity

A ferrate, oxidation treatment technology, applied in water/sludge/sewage treatment, oxidation treatment of sludge, biological water/sewage treatment, etc. Sewage treatment efficiency and other issues, to avoid sludge bulking problems, simple equipment, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

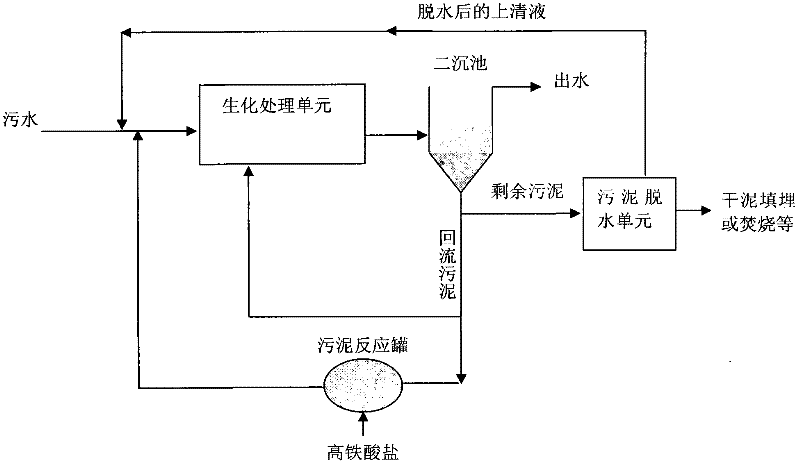

Method used

Image

Examples

Embodiment 1

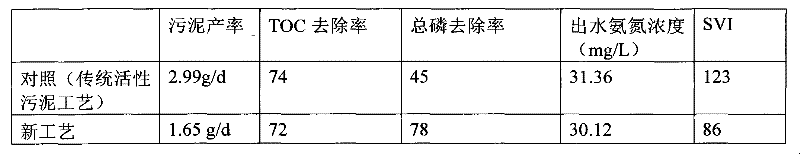

[0021] Example 1: The sewage biological treatment system used in this test is a laboratory-scale fully mixed traditional activated sludge process, which does not have the function of biological nitrogen and phosphorus removal. The effective volume of the aeration tank is 12.5L, and the effective volume of the sedimentation tank is 2.2L. There are 2 sets of test devices, input domestic sewage of the same water quality (COD is 600mg / L, BOD is 600mg / L, BOD 5 is 260mg / L, the total nitrogen concentration is 80mg / L, the ammonia nitrogen concentration is 40mg / L), and the hydraulic retention time is 6 hours. The aeration tank is continuously aerated, the mud-water mixture in the aeration tank enters the sedimentation tank, and all the sludge in the sedimentation tank flows back into the aeration tank, so that the sludge concentration (MLSS) in the aeration tank gradually increases. When the sludge concentration in the aeration tank (mixed liquid suspended solids MLSS) exceeds 4000mg / ...

Embodiment 2

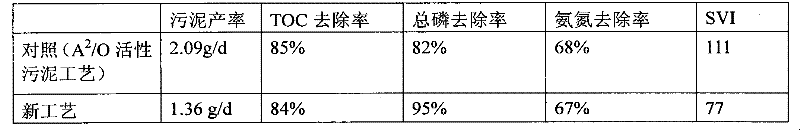

[0024] Embodiment 2: Different from Embodiment 1, the sewage biological treatment system adopts A 2 The / O activated sludge process has the function of biological nitrogen and phosphorus removal. The effective volume of the anaerobic tank and the anoxic tank is 2.5L, the effective volume of the aerobic tank is 7.5L, and the effective volume of the sedimentation tank is 3L. There are 2 sets of test devices in total. Domestic sewage of the same water quality (COD is 600mg / L, BOD is 600mg / L, BOD 5260mg / L, the total nitrogen concentration is 80mg / L, the ammonia nitrogen concentration is 40mg / L), the hydraulic retention time is 2 hours, and the sludge concentration is 2500mg / L. The effluent from the anaerobic tank enters the anoxic tank, the hydraulic retention time is 2 hours, and the sludge concentration is 2500mg / L. The effluent from the anoxic tank enters the aerobic tank, the hydraulic retention time is 6 hours, the sludge concentration is 3500mg / L, the aerobic tank is conti...

Embodiment 3

[0027] Example 3: An urban sewage treatment plant that processes 200,000 tons of domestic sewage a day produces 35 tons of sludge with a moisture content of 78% every day. With the novel sewage treatment process of the present invention, about one-third of the return sludge per day oxidizes with potassium ferrate (the mass ratio of potassium ferrate to sludge is 0.2), and the reacted sludge enters the biological treatment system. The amount of residual sludge can be reduced by 40% compared with the original activated sludge process, and the annual waste sludge production can be reduced by 5,000 tons. The construction cost of adding sludge storage tanks and corresponding pipelines and pumps (about 300,000 yuan) is deducted from the construction cost, and the cost of adding potassium ferrate and the electricity cost of the pump (about 150,000-200,000 yuan / years). If the sludge is treated with anaerobic digestion, the investment cost can be reduced by nearly 8 million yuan, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com