White light-emitting glass and preparation method thereof

A technology of glass and white light, applied in the field of solid luminescent materials, can solve the problems of complex coating process of phosphor powder, different luminous life of phosphor powder and blue light chip, color difference, etc., to overcome the problems of color difference and color rendering, and avoid complicated coating The effect of simple process and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

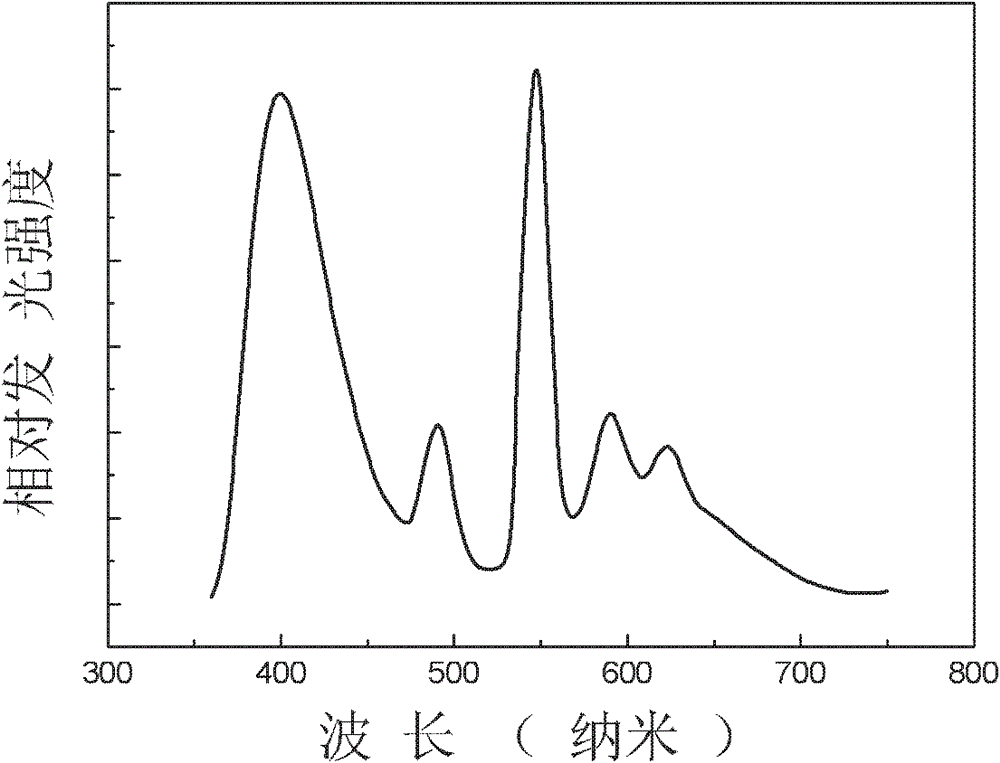

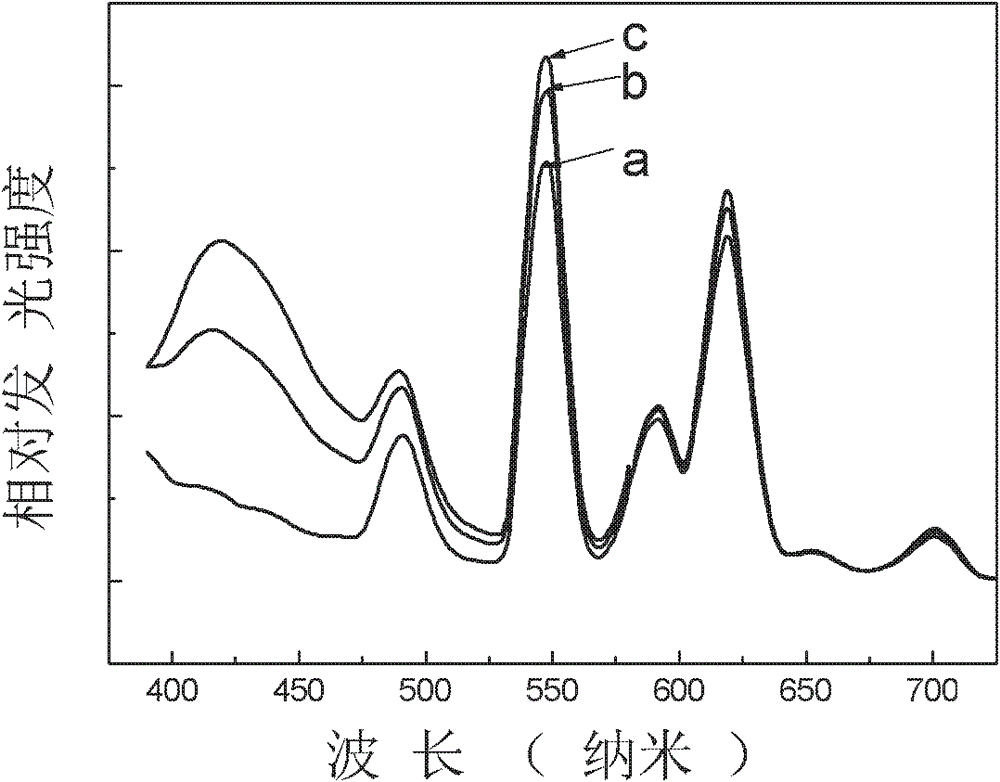

[0013] Using analytically pure SiO 2 、H 3 BO 3 , Mg(CO 3 )·4Mg(OH) 2 ·6H 2 O, ZnO, ZrO 2 , NaCO 3 、Gd 2 o 3 , Sb 2 o 3 、Al 2 o 3 , and 99.99% CeO 2 , Tb 4 o 7 and MnCl 2 As the main raw material, according to 50SiO 2 14B 2 o 3 8MgO 8ZnO 3.5ZrO 2 3Na 2 O 0.4Gd 2 o 3 0.1Sb 2 o 3 10Al 2 o 3 0.8CeO 2 0.8Tb 2 o 3 · 1.5MnO composition Weigh the batch material. After accurate weighing, place it in an agate mortar, grind it for more than half an hour to make it evenly mixed, then put it into a corundum crucible, and reduce the atmosphere in a high-temperature resistance furnace (H 2 :N 2 =5:95) and heated to 1550°C for 3 hours, then quickly pour the molten glass into a copper mold for forming; put the obtained precursor glass into a resistance furnace, anneal at 550°C for 3 hours, then cool with the furnace to Eliminate internal stress. Finally, a colorless and transparent glass is obtained, which emits bright white light under the radiation of 346nm u...

Embodiment 2

[0015] Using analytically pure SiO 2 、H 3 BO 3 , Mg(CO 3 )·4Mg(OH) 2 ·6H 2 O, ZnO, ZrO 2 , NaCO 3 、Gd 2 o 3 , Sb 2 o 3 、Al 2 o 3 , and 99.99% CeO 2 , Tb 4 o 7 and MnCl 2 As the main raw material, according to 48SiO 2 16B 2 o 3 8MgO 8ZnO 3.5ZrO 2 3Na 2 O 0.4Gd 2 o 3 0.1Sb 2 o 3 10Al 2 o 3 0.8CeO 2 1Tb 2 o 3 · 1.5MnO composition Weigh the batch material. After accurate weighing, place it in an agate mortar, grind it for more than half an hour to make it evenly mixed, then put it into a corundum crucible, and reduce the atmosphere in a high-temperature resistance furnace (H 2 :N 2 =7:93) and heated to 1580°C for 2.5 hours, then quickly pour the molten glass into a copper mold for forming; put the obtained precursor glass into a resistance furnace, anneal at 580°C for 2.5 hours, then cool with the furnace to Eliminate internal stress. Finally, a colorless and transparent glass is obtained, which emits bright white light under the irradiation of 365...

Embodiment 3

[0017] Using analytically pure SiO 2 、H 3 BO 3 , Mg(CO 3 )·4Mg(OH) 2 ·6H 2 O, ZnO, ZrO 2 , NaCO 3 、Gd 2 o 3 , Sb 2 o 3 、Al 2 o 3 , and 99.99% CeO 2 , Tb 4 o 7 and MnCl 2 As the main raw material, according to 45SiO 2 19B 2 o 3 8MgO 8ZnO 3.5ZrO 2 3Na 2 O 0.4Gd 2 o 3 0.1Sb 2 o 3 10Al 2 o 3 0.8CeO 2 0.8Tb 2 o 3 · 1.8MnO composition Weigh the batch material. After accurate weighing, place it in an agate mortar, grind it for more than half an hour to make it evenly mixed, then put it into a corundum crucible, and reduce the atmosphere in a high-temperature resistance furnace (H 2 :N 2=2:98) and heated to 1600°C for 2 hours, then quickly pour the molten glass into a copper mold for forming; put the obtained precursor glass into a resistance furnace, anneal at 600°C for 2 hours, then cool with the furnace to Eliminate internal stress. Finally, a colorless and transparent glass is obtained, which emits bright white light under the irradiation of 380nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com