Method for pre-sintering soft magnetic manganese-zinc high-permeability powder in microwave kiln and preparation method of soft magnetic manganese-zinc high-permeability powder

A microwave sintering and microwave frequency technology, applied in the field of electromagnetic materials, can solve the problems of consumption of large petrochemical resources or electric energy, uneven heating of materials, unstable product quality, etc., to reduce energy consumption, high product quality stability, and shorten production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

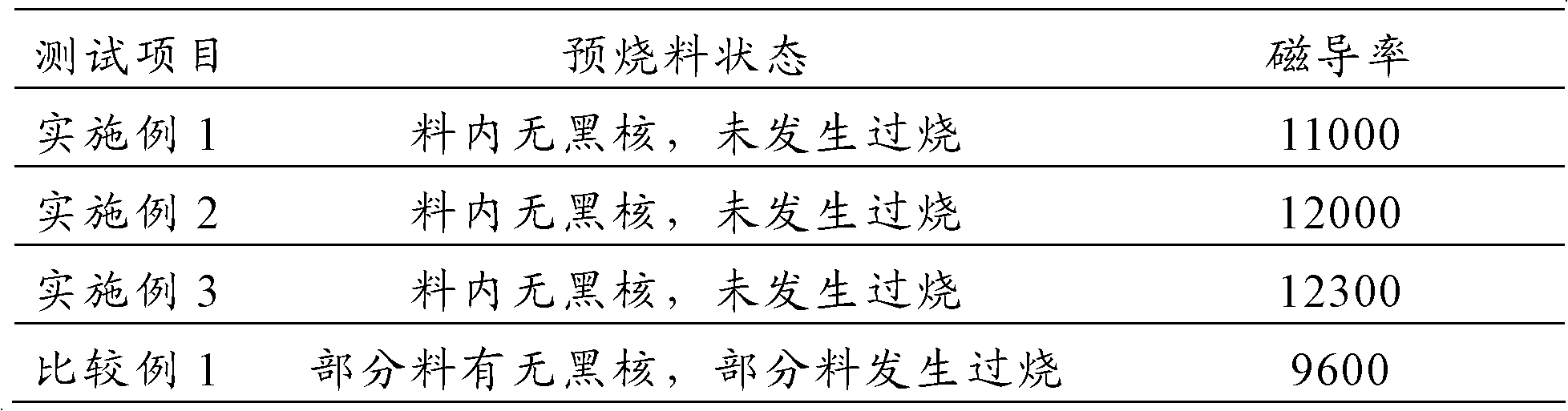

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of manganese zinc ferrite powder, the method comprising:

[0036] Send the manganese-zinc-ferrite mixture into a microwave high-temperature kiln for microwave sintering. The microwave frequency of microwave sintering is 2450MHz, and the sintering temperature is 700°C-900°C to obtain pre-sintered material;

[0037] The calcined material is sequentially cooled, sand-milled and spray-granulated to obtain manganese-zinc ferrite powder.

[0038] The preparation method of the manganese-zinc ferrite powder provided by the present invention is to pre-calcin the manganese-zinc ferrite mixture according to the above method, and then perform cooling, sand milling and spray granulation in sequence. The preferred schemes for the preparation method, sintering temperature and sintering time of the manganese-zinc-ferrite mixture in the pre-sintering process are consistent with the above contents.

[0039]After pre-fired, a black...

Embodiment 1

[0051] 1. Mix 70.2 wt% of ferric oxide, 14.3 wt% of trimanganese tetraoxide and 15.5 wt% of zinc oxide according to the proportion, and use a ball mill to mix to obtain a red solid mixed raw material. The red solid mixed raw material was added with water, stirred and then dried to obtain blocky red solid mixed material.

[0052] 2. Put the massive red solid mixture obtained in step 1 into the high-temperature zone of the microwave high-temperature kiln along with the roller table for microwave sintering. The microwave frequency is 2450MHz, the total power is 75KW, and the temperature in the high-temperature zone is controlled at 750°C. 10Kg, enter the high temperature zone at a speed of 10 boards / hour for 30 minutes to fully cure the reaction. Then the pre-fired material is sent to the cooling zone for cooling, and then exits the kiln to obtain the pre-fired material.

[0053] 3. Send the pre-fired material obtained in step 2 into a sand mill, and add 0.18wt% of the weight of...

Embodiment 2

[0057] 1. Mix 70.2 wt% of ferric oxide, 14.3 wt% of trimanganese tetraoxide and 15.5 wt% of zinc oxide according to the proportion, and use a ball mill to mix to obtain a red solid mixed raw material. The red solid mixed raw material is added with water, stirred and then dried to obtain blocky red solid mixed material.

[0058] 2. Put the lumpy red solid mixture obtained in step 1 into the high-temperature zone of the microwave high-temperature kiln along with the roller table for microwave sintering. The microwave frequency is 2450MHz, the total power is 75KW, and the temperature in the high-temperature zone is controlled at 800°C. 10Kg, enter the high temperature zone at a speed of 10 boards / hour for 60 minutes to fully cure the reaction. Then the pre-fired material is sent to the cooling zone for cooling, and then exits the kiln to obtain the pre-fired material.

[0059] 3. Send the pre-fired material obtained in step 2 into a sand mill, and add 0.18wt% of the weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com