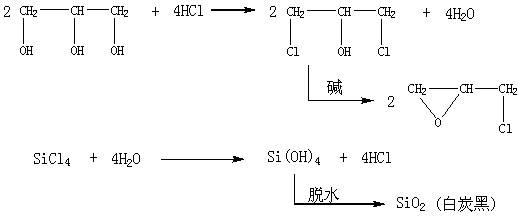

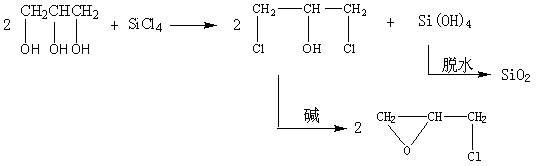

Method using glycerol and silicon tetrachloride to prepare epichlorohydrin and white carbon black

A technology of epichlorohydrin and silicon tetrachloride, applied in the directions of silicon oxide, silicon dioxide, organic chemistry, etc., can solve the problems of inhibition and high energy consumption, and achieve the advantages of preventing clogging, improving reaction selectivity and reducing product cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1. Continuous operation in a tubular reactor

[0039] Dissolve adipic acid (catalyst) in crude glycerol with a glycerin content of 89% (mass ratio) (obtained from the crude glycerol produced by-product of biodiesel production and treated with acid clay, the mass composition is: glycerin 89%, water 7%, 0.8% of salt, 3.2% of others), and a 5% (mass ratio) crude glycerol solution of the catalyst was prepared. Use a metering pump to press the crude glycerol containing the catalyst into a tubular reactor with a total volume of 75L at a rate of 8.0kg / h. The tubular reactor is divided into two parts, the front part and the former. The tube is 24m long), and the reaction temperature is controlled at 80°C; the volume of the latter part of the tubular reactor is 45L (DN40mm tube, 36m long), and the reaction temperature is controlled at 120°C.

[0040] SiCl with a mass content of 96% 4Dissolved in 1,2-dichloroethane to make 40% (mass ratio) SiCl 4 dichloroethane solut...

Embodiment 2

[0046] Embodiment 2. Tank reactor batch operation

[0047] at a volume of 0.25 m 3 Add 70kg of industrial glycerin with a content of 95% (mass ratio) (obtained from biodiesel by-product glycerol through vacuum distillation) into the external circulation reactor, and add 10 kg of glacial acetic acid. Close the feeding port and start the circulation pump.

[0048] 71kg of SiCl with a content of 96% (mass ratio) 4 Dissolved with 34kg N,N-dimethylformamide to make 65% (mass ratio) SiCl 4 Dimethylformamide solution 105kg. Press the SiCl at a rate of 35kg / h through the feed pipe with a metering pump 4 The solution was cooled by jacket water to control the reaction temperature to 90°C for 1 hour. Subsequently, the reaction temperature was controlled to 120° C. to continue the reaction for 2 hours.

[0049] A total of 65% (mass ratio) of SiCl was pumped into 4 DMF solution 105kg, glycerin and SiCl 4 The molar ratio is 1.8:1, the operating pressure is 0.6~1.0MPa, and the tota...

Embodiment 3

[0053] Example 3. Tower reactor continuous operation

[0054] Dissolve phosphotungstic acid in 82% crude glycerin (by-product of biodiesel production) to make 4% catalyst glycerin solution. Use a metering pump to press the catalyst-containing crude glycerin into the tower reactor at a rate of 88 kg / h. The tower reactor consists of two parts connected in series with an external circulation pump, the volume of the first tower is 0.8m 3 , the volume of the second tower is 1.2m 3 .

[0055] SiCl with a mass content of 96% 4 Dissolved with ethylene glycol dimethyl ether to make 25% (mass ratio) SiCl 4 Ethylene glycol dimethyl ether solution. Use a metering pump to mix 25% SiCl 4 The solution is pressed into the above-mentioned tower reactor at a rate of 220kg / h. Glycerin and SiCl 4 The molar ratio is 2.3:1.

[0056] SiCl 4 The solution enters the tower reactor in two distribution ways, one of which is 40% SiCl 4 The solution is sent to the first tower reactor, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com