Macroporous resin microspheres and preparation method and application thereof

A macroporous resin and microsphere technology, which is applied in chemical instruments and methods, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of low mechanical strength and easy breakage of macroporous resin microspheres, and achieve uniform acid and alkali resistance, Good acid and alkali resistance, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

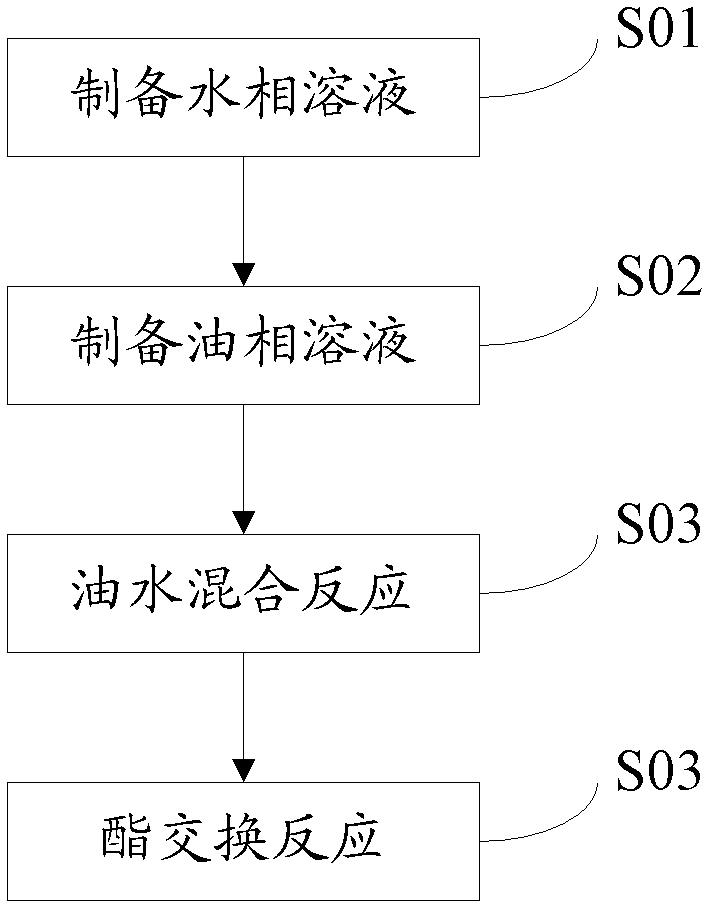

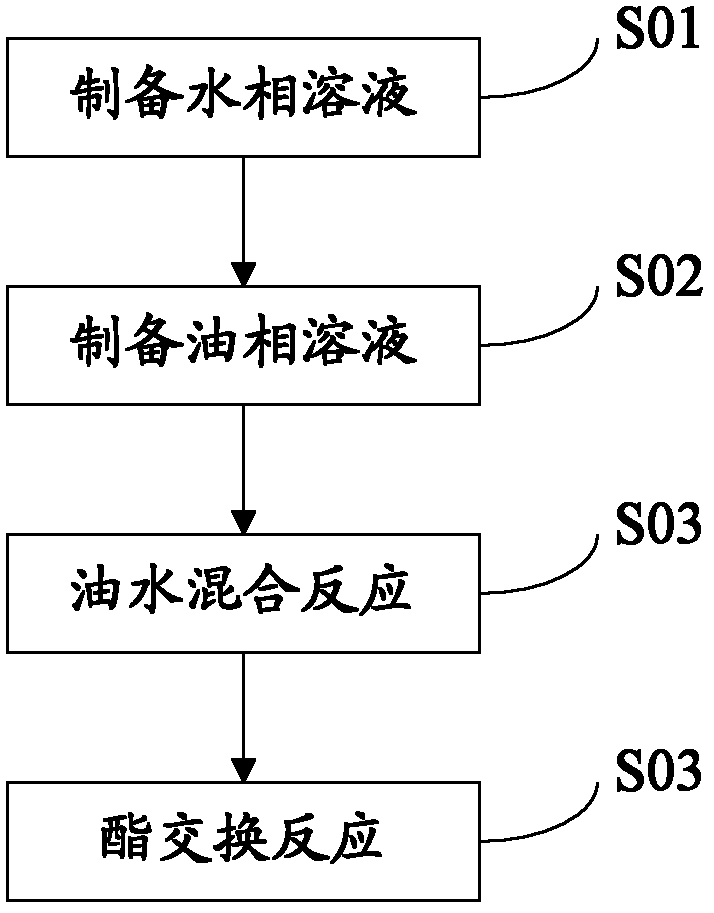

[0021] see figure 1 , figure 1 Show the flowchart of the method for preparing macroporous resin microspheres in the embodiment of the present invention, including the following steps:

[0022] Step S01, preparing an aqueous phase solution:

[0023] preparing an aqueous phase solution containing 1.8% to 2.4% by weight of polyvinyl alcohol and 2% to 6% by weight of sodium chloride;

[0024] Step S02, preparing an oil phase solution:

[0025] Mix the punching agent, styrene, acrylate monomer and divinylbenzene in a weight ratio of 100:80-120:100-150 to obtain an oil phase mixture, and add the oil phase mixture to the water phase solution , stirring to obtain an oil phase solution, the ratio of the punching agent to the total weight of the styrene, acrylate monomer and divinylbenzene is 0.2 to 0.25:1, the weight of the oil phase mixture and the water phase solution The ratio is 1:8~12;

[0026] Step S03, oil-water mixing reaction:

[0027] Add the toluene solution containing...

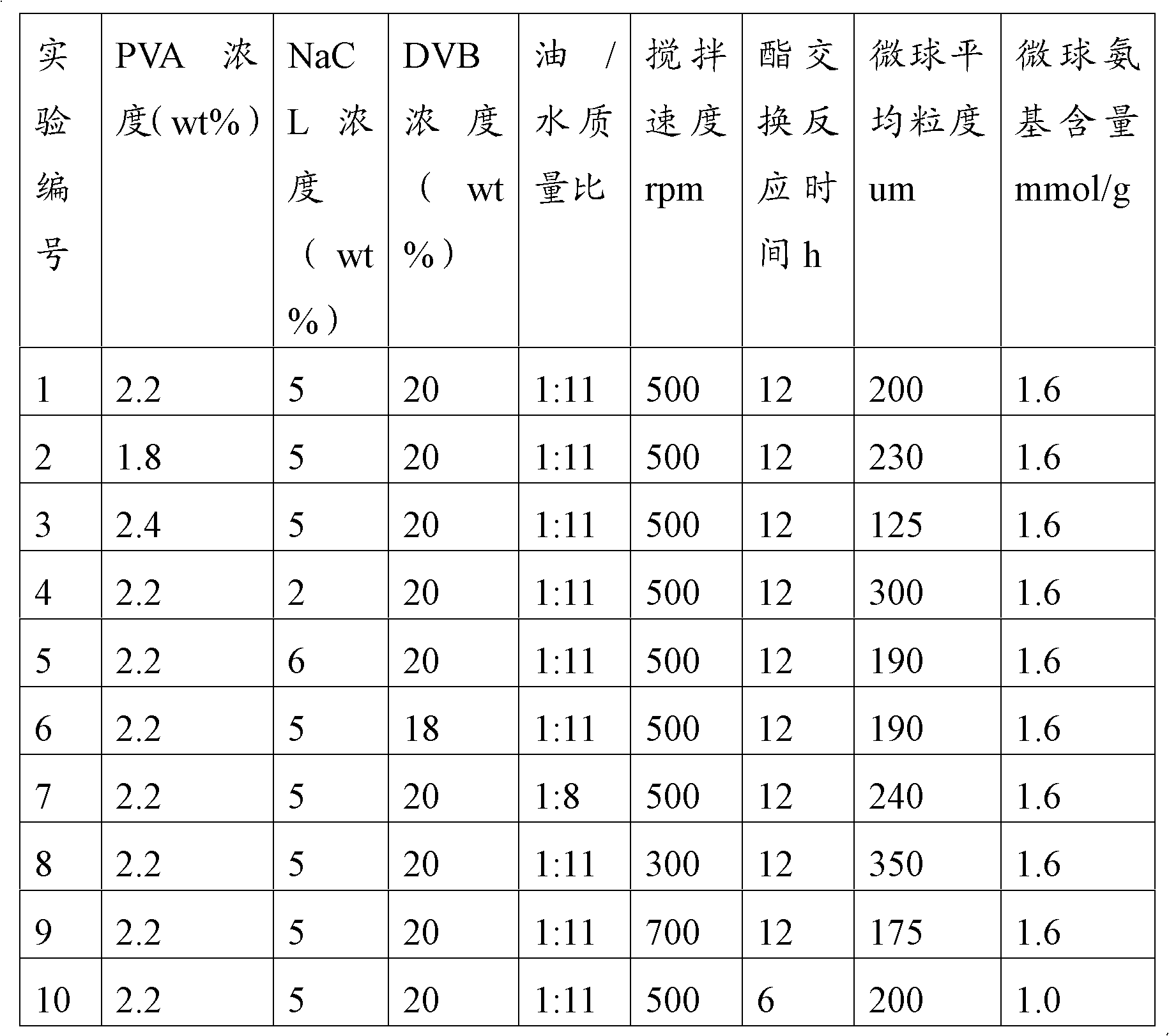

Embodiment 1

[0053] Take 2.42g of PVA and 5.50g of NaCl, add them to 102g of distilled water, heat to dissolve at 90°C, filter to remove trace suspended impurities, and obtain transparent PVA and NaCl aqueous solutions with different contents, that is, the continuous phase water phase;

[0054] The continuous water phase is composed of PVA and NaCl aqueous solution, which is added to a three-port reactor equipped with a stirrer, a condenser tube, and an air guide tube;

[0055] Take 3.0g, 3.0g, 4.0g, and 1.5g of styrene, methyl methacrylate, divinylbenzene, and n-dodecane. After mixing completely, add them to water, add 1.5g of toluene solution containing 0.03g of AIBN, and form dispersed phase oil phase;

[0056] The water phase of the continuous phase and the oil phase of the dispersed phase are in a weight ratio of 11:1, and the oil phase of the dispersed phase is added to the reactor, and the two phases are fully dispersed at a mechanical stirring speed of 500 rpm, and then nitrogen is...

Embodiment 2

[0059] Take 2.20g of PVA and 6.60g of NaCl, add them to 101.2g of distilled water, heat and dissolve at 90°C, filter to remove trace suspended impurities, and obtain transparent PVA and NaCl aqueous solutions with different contents, that is, the continuous phase water phase;

[0060] The continuous water phase is composed of PVA and NaCl aqueous solution, which is added to a three-port reactor equipped with a stirrer, a condenser tube, and an air guide tube;

[0061] Get styrene, methyl methacrylate, divinylbenzene, n-dodecane 3.0g, 3.0g, 4.8g, 1.5g, after mixing completely, add into water, add 1.03g toluene solution containing 0.03g BPO (ie Dissolve 0.03 gram of BPO with 1.0 gram of toluene), constitute the dispersed phase oil phase;

[0062] The water phase of the continuous phase and the oil phase of the dispersed phase are in a weight ratio of 11:1, and the oil phase of the dispersed phase is added to the reactor, and the two phases are fully dispersed at a mechanical sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com