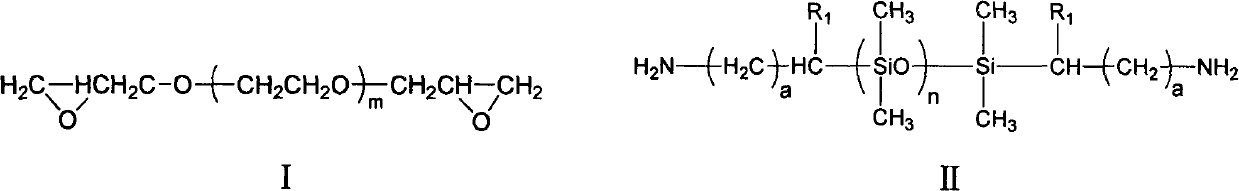

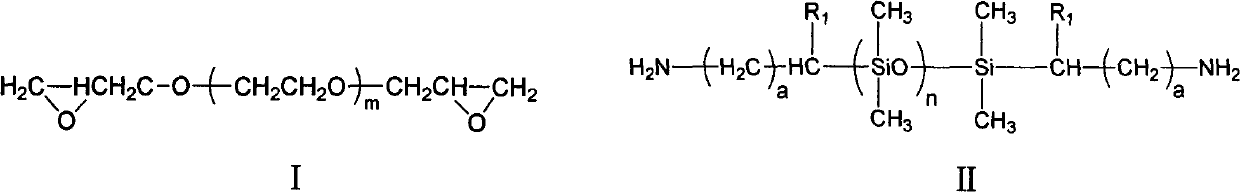

Polyether/aminopolysiloxane block copolymer and use thereof

An aminopolysiloxane, block copolymer technology, applied in the direction of plant fibers, fiber types, textiles and papermaking, etc., can solve the problem of high shear sensitivity, affecting soft and fluffy feeling, and amino-modified silicone softeners cannot. Problems such as direct use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

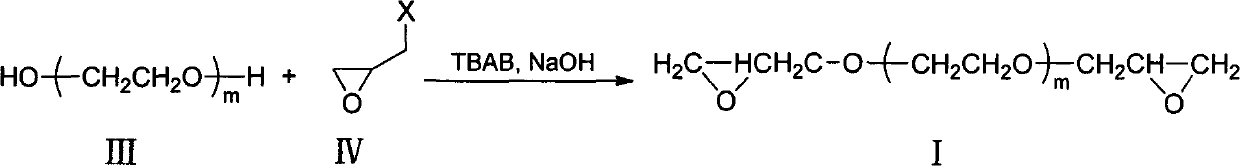

[0027] Preparation of ASPC-1:

[0028] (1) Add 20.0g of polyethylene glycol-200, 16.0g of sodium hydroxide, 1.93g of tetrabutylammonium bromide and 28.5g of dichloromethane into a three-necked flask. 37.0 g of epichlorohydrin was added dropwise, and the reaction was stopped at 55° C. for 6 hours after the dropwise addition was completed. After the reaction is completed, the generated inorganic salts are removed by filtration, the dichloromethane layer is washed three times with water, and then dried with anhydrous sodium sulfate, dichloromethane and excess epichlorohydrin are evaporated under reduced pressure to obtain an epoxy-terminated polyether intermediate;

[0029] IR (tablet method): 2869.86 (s, υCH 2 -O), 1457.30 (w, δ-CH 2 -), 1109.32 (s, υ-CH 2 -O-CH 2 -), 855.17 (w, δ-CH 2 OCH 2 -).

[0030] (2) Add 15.6g of the epoxy-terminated polyether intermediate prepared in step (1) and 30g of isopropanol into a three-necked flask, heat to 50°C under nitrogen protection...

Embodiment 2

[0033] Preparation of ASPC-2:

[0034] (1) Add 20.0g of polyethylene glycol-200, 12.0g of sodium hydroxide, 1.93g of tetrabutylammonium bromide and 14.3g of chloroform into a three-necked flask, and add them dropwise in an ice-water bath at 0-5°C 27.8g of epichlorohydrin, the reaction was stopped at 65°C for 6 hours after the dropwise addition was completed. After the reaction is completed, the generated inorganic salts are removed by filtration, the chloroform layer is washed three times with water, and then dried with anhydrous sodium sulfate, and the chloroform and excess epichlorohydrin are evaporated under reduced pressure to obtain an epoxy-terminated polyether intermediate;

[0035] IR (tablet method): 2868.70 (s, υCH 2 -O), 1458.55 (w, δ-CH 2 -), 1109.72 (s, υ-CH 2 -O-CH 2 -), 856.38 (w, δ-CH 2 OCH 2 -).

[0036] (2) Add 31.2g of the epoxy-terminated polyether intermediate prepared in step (1) and 10g of isopropanol into a three-necked flask, heat to 50°C under ...

Embodiment 3

[0039] Preparation of ASPC-3:

[0040] (1) Add 40.0g of polyethylene glycol-400, 12.0g of sodium hydroxide, 2.34g of boron trifluoride etherate and 34.0g of tetrahydrofuran into a three-necked flask. 27.8 g of epichlorohydrin was added dropwise, and the reaction was stopped at 70° C. for 6 hours after the dropwise addition was completed. After the reaction is complete, remove the generated inorganic salt by filtration, wash the tetrahydrofuran layer with water three times, and then dry it with anhydrous sodium sulfate, distill off tetrahydrofuran and excess epichlorohydrin under reduced pressure to obtain an epoxy-terminated polyether intermediate;

[0041] IR (tablet method): 2869.24 (s, υCH 2 -O), 1457.97 (w, δ-CH 2 -), 1110.21 (s, υ-CH 2 -O-CH 2 -), 855.98 (w, δ-CH 2 OCH 2 -).

[0042] (2) Add 25.6g of the epoxy-terminated polyether intermediate prepared in step (1) and 30g of isopropanol into a three-necked flask, heat to 50°C under nitrogen protection, and add 103....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com