Organic silicon-polyurethane-acrylate composite coating agent crosslinked at room temperature and preparation method thereof

A room temperature cross-linking, acrylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor compatibility and poor mechanical properties of composite systems, and achieve high product quality, low cost, and investment. The effect of high output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

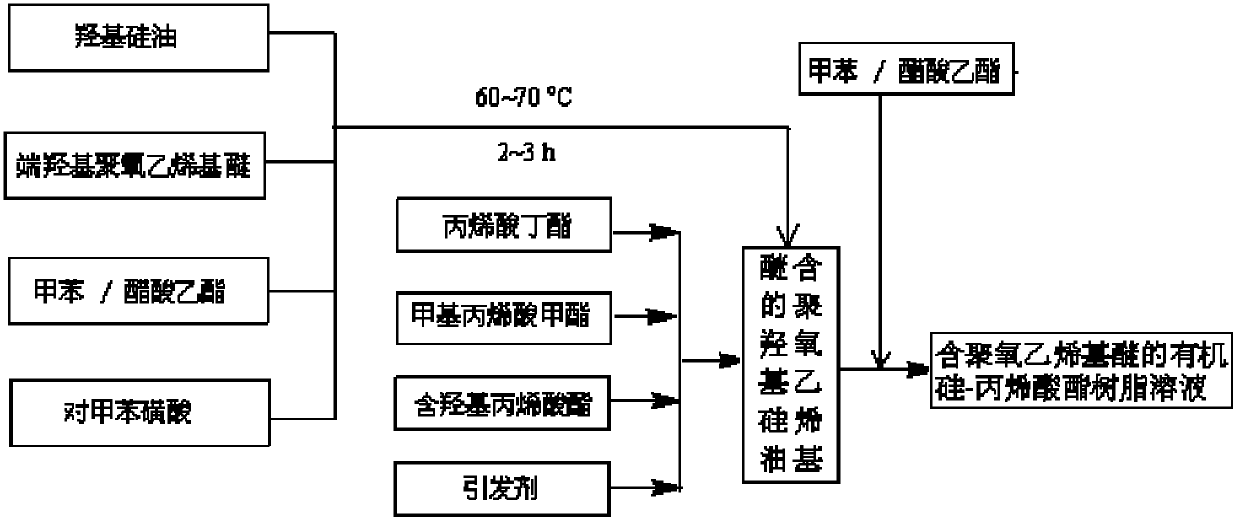

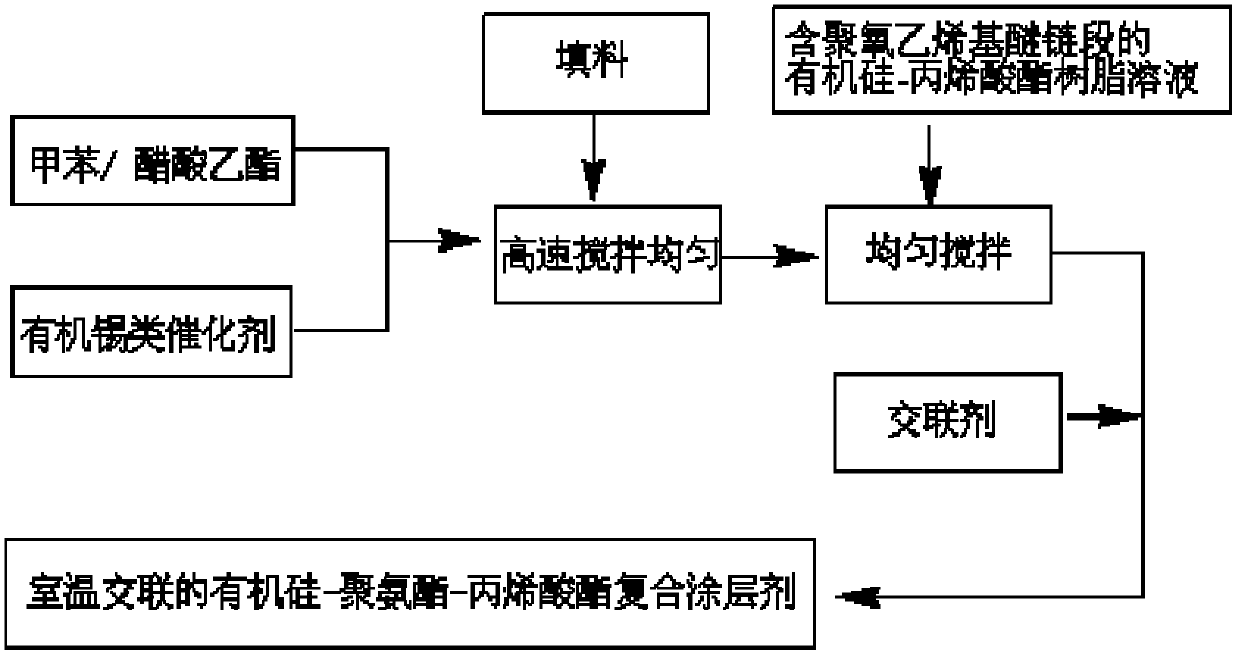

[0035] Dissolve 100 mg of hydroxysilicone oil (molecular weight: 2000), 80 mg of hydroxyl-terminated polyoxyethylene ether, 150 mg of toluene, 150 mg of ethyl acetate, and 2.5 mg of p-toluenesulfonic acid, and heat up to 70 o C was reacted for 2 hours to prepare a hydroxyl silicone oil solution containing polyoxyethylene ether.

[0036] Dissolve 100 mg of polyoxyethylene ether-containing hydroxyl silicone oil in a mixed solvent of 100 mg toluene and 90 mg ethyl acetate, heat to 75 o C. Mix 85 mg of methyl methacrylate, 50 mg of butyl acrylate and 6 mg of β-hydroxyethyl methacrylate, and add 1.2 mg of dibenzoyl peroxide. After fully dissolving, slowly add the above-mentioned In the hydroxy silicone oil solution of polyoxyethylene base ether, the control dropwise adding time is 2.5 hours, after adding, add again at 85 o C for 1.5 hours, then add 20 mg of toluene and 25 mg of ethyl acetate, and stir evenly to prepare a polyoxyethylene ether-containing silicone-ac...

Embodiment 2

[0039] The same as in Example 1, but the amount of hydroxyl-terminated polyoxyethylene ether in step (1) was changed from 80 mg to 60 mg, and the others remained unchanged.

Embodiment 3

[0041] Same as Example 1, but the amount of hydroxyl-terminated polyoxyethylene ether in step (1) was changed from 80 mg to 100 mg, and the others remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com