Rare earth polishing material and preparation method thereof

The technology of rare earth polishing and rare earth polishing powder is applied in the field of rare earth polishing materials and their preparation, and can solve the problems of complex compounding process of fluoride and oxide, high true density of rare earth polishing powder, easy precipitation of polishing powder and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] On the other hand, the preparation method of rare earth polishing material of the present invention, it comprises the steps:

[0043] (1) Preparation of rare earth polishing powder:

[0044] Fluorination: mix rare earth carbonate with water, heat to 30-50°C, add a certain amount of 20% hydrofluoric acid solution dropwise under stirring conditions, add 10-15% ammonium bicarbonate aqueous solution to adjust to The pH is 6.5-7, heated to 70-90°C, and kept for 5-10h to obtain partially fluorinated rare earth carbonate slurry;

[0045] Dehydration and drying: After dehydrating the partially fluorinated rare earth carbonate slurry, dry it at 120-200°C for 10-20h;

[0046] Roasting: Roast the above product at 950-1100°C for 4-6 hours to obtain rare earth oxyfluoride;

[0047] Pulverization and classification: The obtained rare earth oxyfluoride is pulverized and classified to obtain the median diameter D 50: 0.8-3.0μm rare earth polishing powder;

[0048] (2) Preparation o...

Embodiment 1

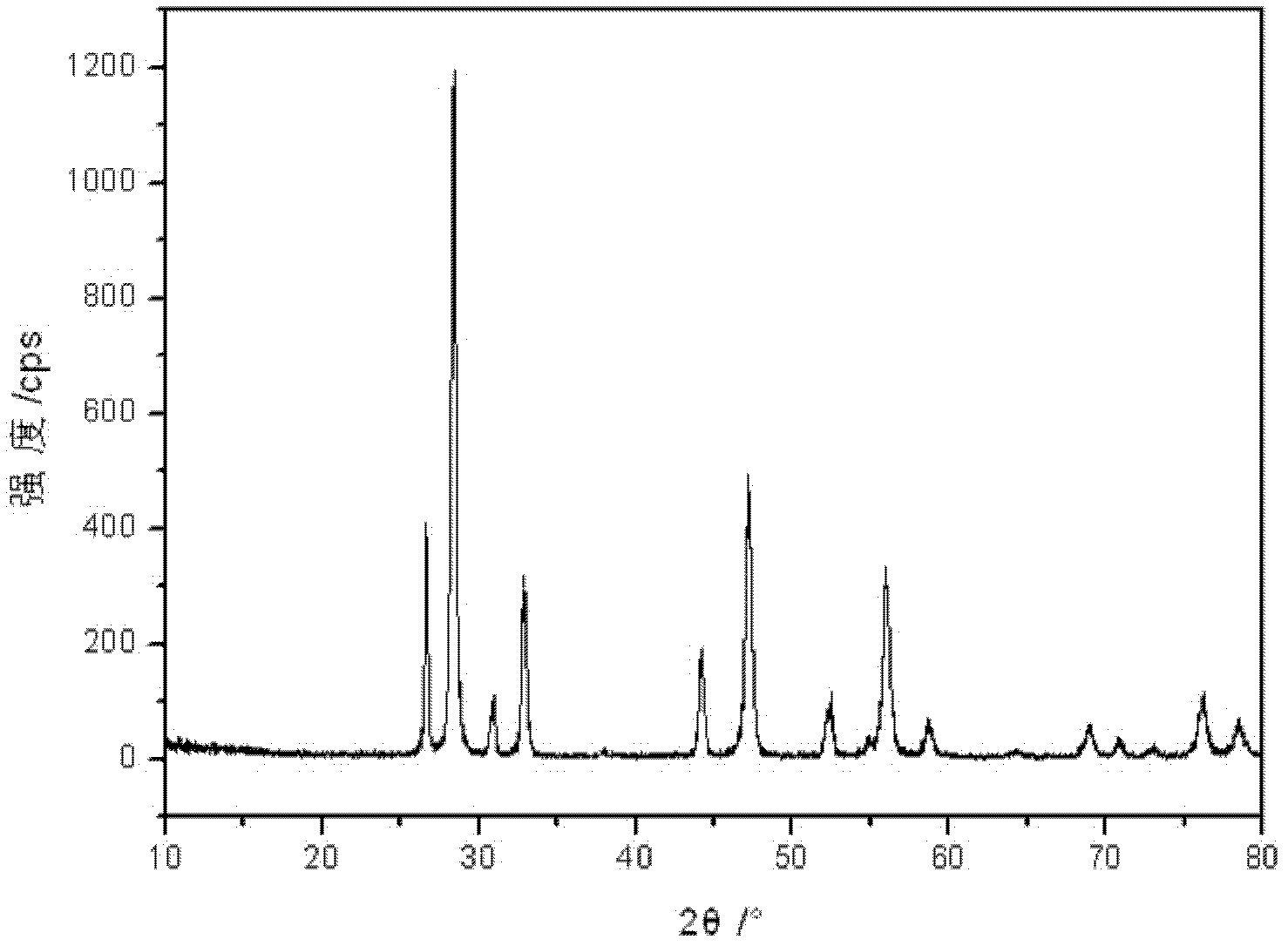

[0054] Mix 1000kg of lanthanum cerium carbonate with 1000kg of water, heat to 30°C, add 80kg of 20% hydrofluoric acid dropwise, heat to 70°C after the dropwise addition, and keep warm for 10h to obtain partially fluorinated lanthanum cerium carbonate slurry; The partially fluorinated lanthanum cerium carbonate slurry was dehydrated by centrifugation, dried at 200°C for 10h, and calcined at 1100°C for 4h. Then it is pulverized and classified by airflow to obtain rare earth polishing powder. Tested by laser particle size analyzer, product D 50 =0.81μm, XRD results see figure 1 .

[0055] Fully mix 98 parts of rare earth polishing powder, 1 part of polyacrylic acid, 1 part of microcrystalline cellulose, and 0.05 part of sodium bicarbonate to obtain the rare earth polishing material.

Embodiment 2

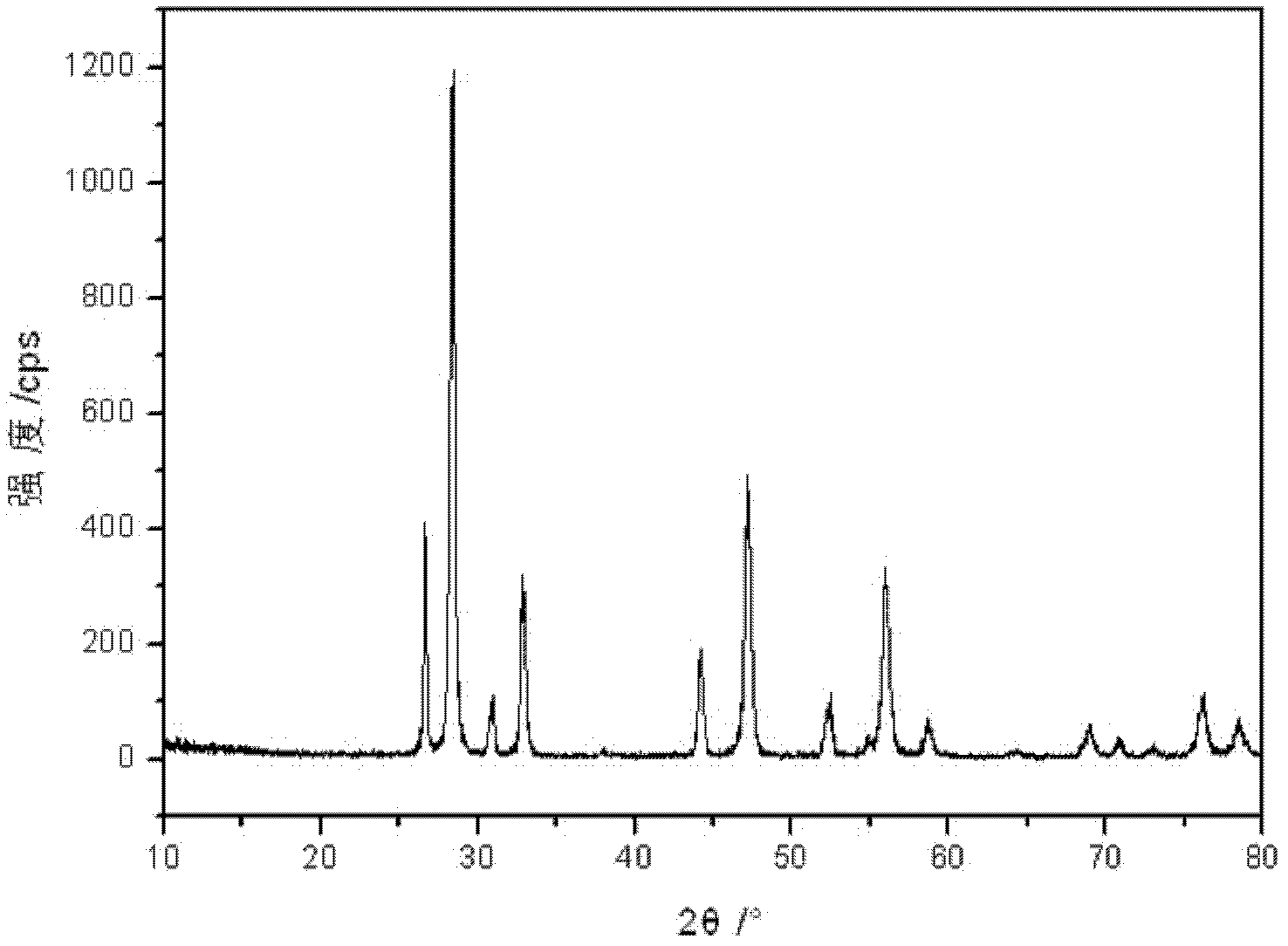

[0057] Mix 1000kg of lanthanum cerium carbonate with 1000kg of water, heat to 50°C, add 160kg of 20% hydrofluoric acid dropwise, heat to 90°C after the dropwise addition, and keep warm for 5 hours to obtain partially fluorinated lanthanum cerium carbonate slurry; The obtained partially fluorinated lanthanum-cerium-praseodymium carbonate slurry was centrifuged and dehydrated, dried at 120°C for 20 hours, and calcined at 950°C for 6 hours; then crushed and classified by airflow to obtain rare earth polishing powder. Tested by laser particle size analyzer, product D 50 =2.98μm, XRD results see figure 2 .

[0058] Fully mix 65 parts of rare earth polishing powder, 5 parts of polyacrylic acid, 10 parts of agar gum, 15 parts of guar gum, 5 parts of ara gum, and 0.3 part of sodium carbonate to obtain the rare earth polishing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com