Method for quickly separating chain hydrocarbon and phenols from medium and low temperature tar

A low-temperature tar, low-temperature coal tar technology, applied in the direction of tar processing by selective solvent extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

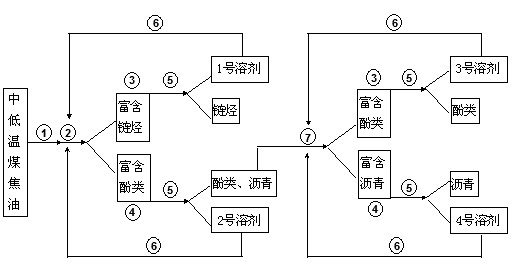

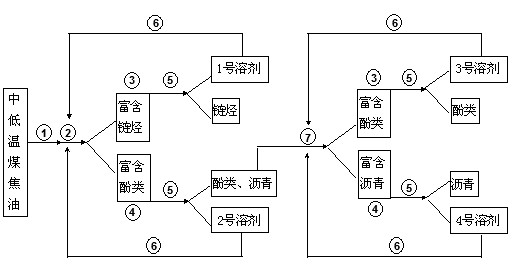

Image

Examples

Embodiment 1

[0025] The first type of biphasic organic solvent A: Slowly add n-hexane solvent and cyclohexanone solvent under the condition of sufficient stirring, the volume ratio of n-hexane solvent and cyclohexanone solvent is 1:6; then add a total volume of 2.0‰ by weight Ratio of polycarbamide alcohol, fully mixed system, layered after static, that is, prepared into biphasic organic solvent A;

[0026] The second type of biphasic organic solvent B: Slowly add glycerol and carbon tetrachloride solvent under the condition of sufficient stirring, the volume ratio of glycerol and carbon tetrachloride solvent is 1:6; then add a total volume of 1.5‰ weight Ratio of polycarbonate alcohols, after fully mixing the system to stand still, after layering, it is prepared into a biphasic organic solvent B.

[0027] 2. Method and process for the enrichment and separation of medium chain hydrocarbons and phenolic components of medium and low temperature tar:

[0028] Add medium and low temperature c...

Embodiment 2

[0033] The first type of biphasic organic solvent A: Slowly add kerosene solvent and isopropanol solvent under the condition of sufficient stirring, the volume ratio of kerosene solvent and isopropanol solvent is 1:4; then add the total volume of 1.5‰ weight ratio Polycarbamin alcohol, fully mixed system, layered after static, that is, prepared into biphasic organic solvent A;

[0034] The second type of biphasic organic solvent B: Slowly add chloroform solvent and oil washing solvent under the condition of sufficient stirring, the volume ratio of chloroform solvent and oil washing solvent is 1:8; then add polycarbonate with a total volume of 2.5‰ weight ratio Amino alcohol, after fully mixing the system to stand still, the two-phase organic solvent B is prepared after layering.

[0035] 2. Method and process for the enrichment and separation of medium chain hydrocarbons and phenolic components of medium and low temperature tar:

[0036] To the first type of biphasic organic ...

Embodiment 3

[0041] The first type of biphasic organic solvent A: Slowly add petroleum ether solvent and butanone solvent under the condition of sufficient stirring, the volume ratio of petroleum ether solvent and methyl ethyl ketone solvent is 1:8; then add the total volume of 3.2‰ weight ratio Polycarbamin alcohol, fully mixed system, layered after static, that is, prepared into biphasic organic solvent A;

[0042] The second type of biphasic organic solvent B: Slowly add acetone solvent and carbon disulfide solvent under the condition of sufficient stirring, the volume ratio of acetone solvent and carbon disulfide solvent is 1:5; then add polycarbamide alcohol with a total volume of 2.0‰ weight ratio , after fully mixing the system to stand still and separate the layers, the biphasic organic solvent B is prepared.

[0043] 2. Method and process for the enrichment and separation of medium chain hydrocarbons and phenolic components of medium and low temperature tar:

[0044] Add medium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com