Preparation method of lactic acid by saccharifying and fermenting lignocellulose

A technology of lignocellulose and cellulase, which is applied in the direction of fermentation, can solve the problems of less research and application of lactic acid, low lactic acid concentration, and high production cost, and achieve low substrate cost, high lactic acid concentration and yield, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

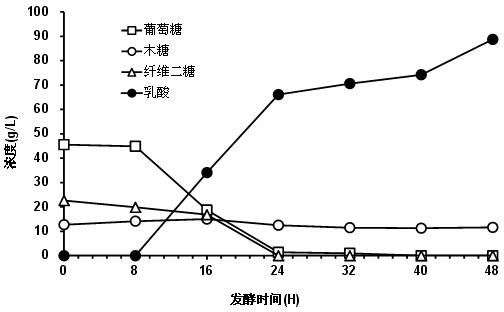

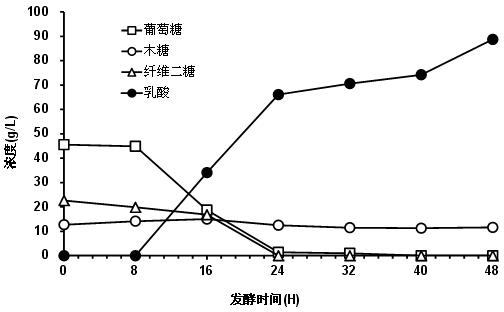

[0039] Dried corn stalks were mixed with dilute sulfuric acid solution until the water content was 33%, the sulfuric acid concentration was 2.5%, and pretreated at 190°C for 3min; Solid state culture for 7 days; Harvest the material without high-temperature sterilization, add it to the fermenter, the solid content in the fermenter is 30% by mass, the amount of cellulase is 15 FPU / g DM, pre-saccharification at 50°C for 10 hours, 5M hydrogen Sodium oxide controlled the pH of the fermentation process at 5.5, and fermented at 42°C for 48 hours. Because the process adds a large amount of lye, the final volume calculation solid content is 26.7%.

[0040] The Pediococcus acidilactici used in the examples is Pediococcus acidilactici DQ2 isolated and preserved from lignocellulose.

[0041] Pediococcus acidilactici DQ2 is isolated from lignocellulose hydrolyzate, spread the hydrolyzate sample containing microorganisms on YPD medium agar plate, culture at 42°C, and test whether the grow...

Embodiment 2

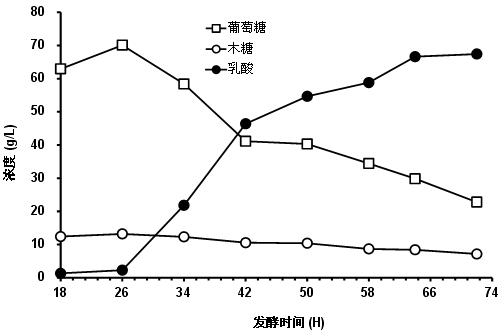

[0043] Dried corn stalks are mixed with dilute sulfuric acid solution until the water content is 33%, the sulfuric acid concentration is 2.5%, and pretreated at 190°C for 3 minutes. After the pretreatment, the material is adjusted to pH 5.4, and the water content is 58%. Solid state culture for 4 days; Harvest the material, store the material in a refrigerator at 4°C for half a month, the material is not sterilized, add 30% solid mass fraction to the fermenter, add enzyme amount 13FPU / g DM, use 5M sodium hydroxide solution to control pH 5.0, 42 ℃ fermentation.

Embodiment 3

[0045]The dried corn stalks were mixed with dilute sulfuric acid solution until the water content was 33%, the sulfuric acid concentration was 2.5%, and pretreated at 190°C for 3 minutes. After the pretreatment, the material was adjusted to pH 5.4 and the water content was 58%. Add cellulase 15FPU / gDM to the fermenter with a solid mass fraction of 30%, 50°C, pH 5.0, hydrolyze for 48H, centrifuge at 13000rpm for 10min to obtain a supernatant; insert the cultured supernatant into the supernatant containing high sugar concentration Pediococcus lactis seeds were fermented at 42°C, pH 5.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com