Electrostatic spinning preparation method of POSS (Polyhedral Oligomeric Silsesquioxane)-containing polymer composite fiber

An electrospinning and composite fiber technology, which is applied in the field of electrospinning preparation of POSS polymer composite fibers, can solve the problems of affecting the performance of composite materials, POSS agglomeration, poor dispersion of POSS particles, etc. Compatibility, short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concrete steps of preparation are:

[0026] Step 1, first mix the high molecular polymer and the corresponding polymer solvent according to the mass ratio of 2.5:97.5, then place it at a temperature of 30°C and stir for 2 hours to obtain a mixed solution with a concentration of 2.5%; the polymer is three Ethylene-propylene-diene rubber (EPDM), the solvent is tetrahydrofuran;

[0027] Step 2, then mix the soluble POSS (here phenyl-POSS) and the EPDM mixed solution obtained in step 1 according to the mass ratio of POSS:EPDM = 2:98, and stir at a temperature of 30°C for 15min, so that POSS is fully dissolved to obtain a spinning solution;

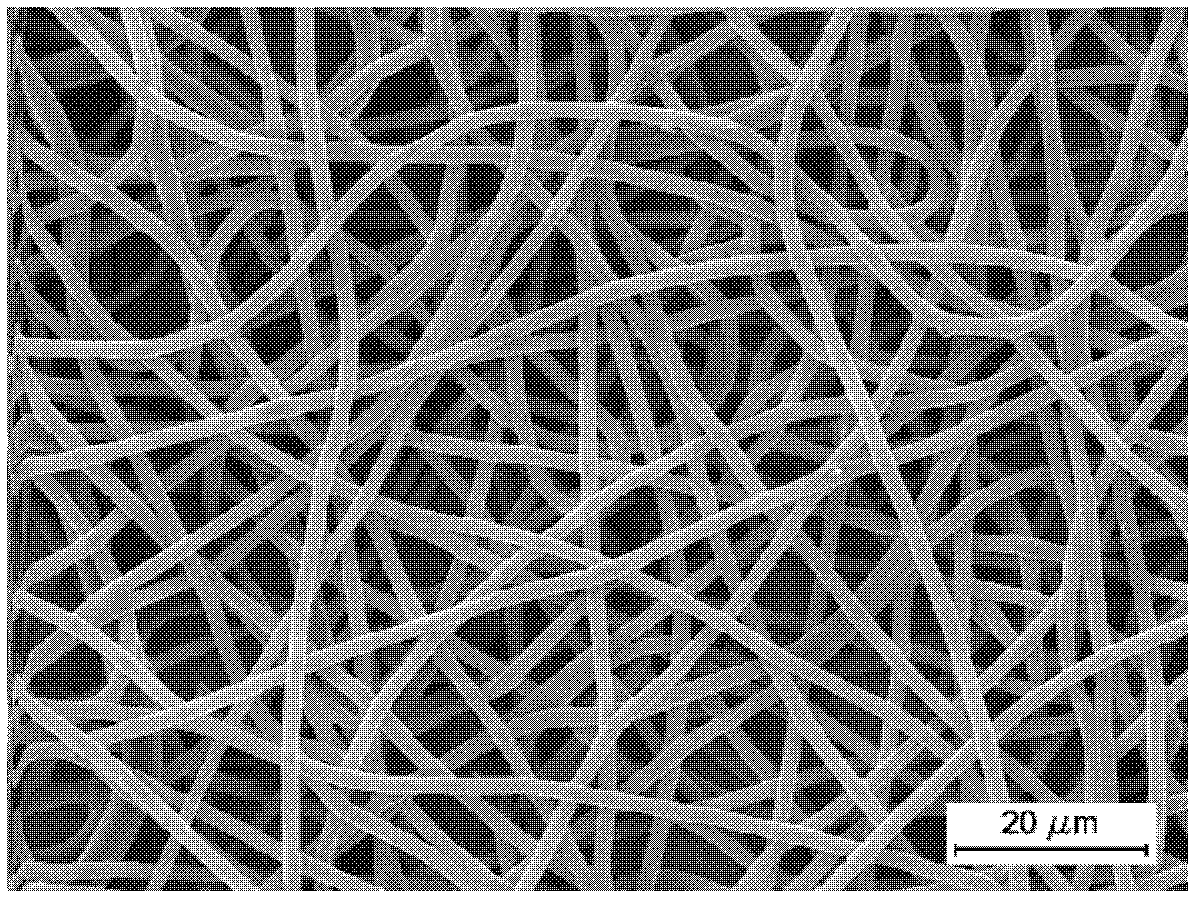

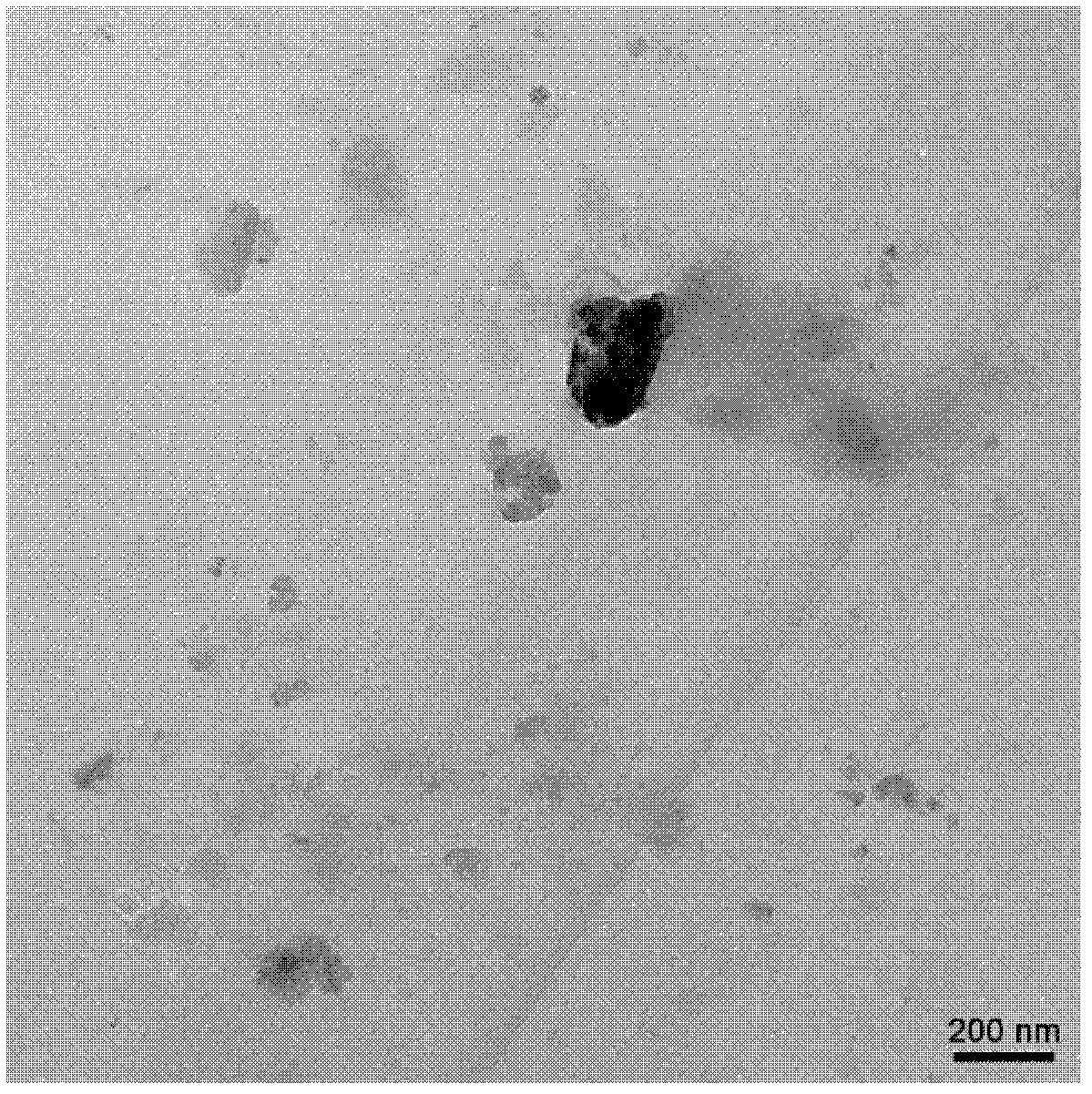

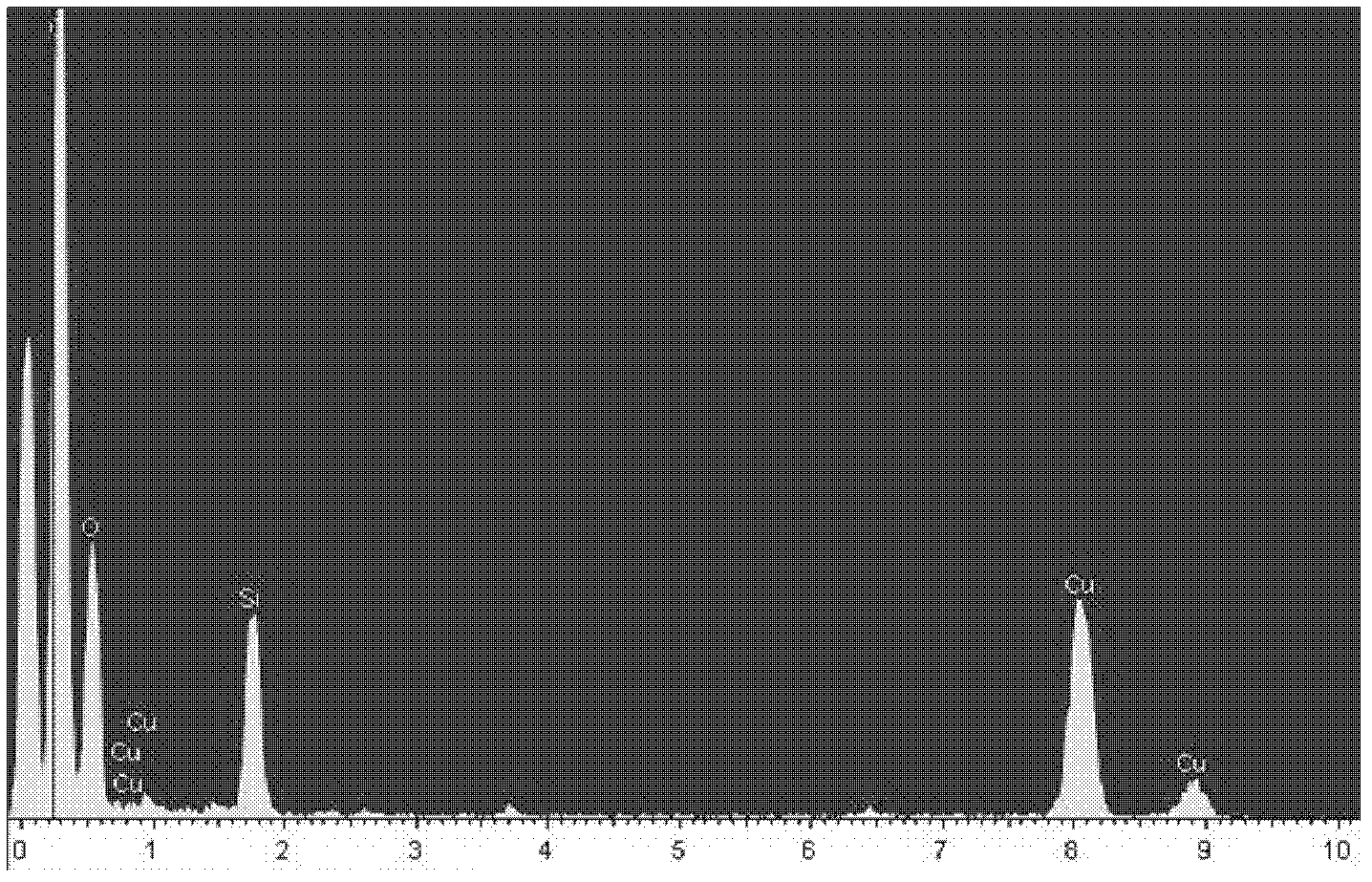

[0028] Step 3, and then the spinning solution is placed on the electrospinning equipment for spinning. The various experimental parameters are: applied voltage 20kV, distance from the spinning needle to the receiving device 20cm, spinning solution flow rate 3.0mL / h, spinning The silk collection method is flat plate collection, whi...

Embodiment 2

[0034] The concrete steps of preparation are:

[0035] Step 1, first mix the high molecular polymer and the corresponding polymer solvent according to the mass ratio of 3:97, and then stir at a temperature of 40°C for 2 hours to obtain a mixed solution of high molecular polymer with a concentration of 3%; Wherein the polymer is EPDM, and the solvent is tetrahydrofuran;

[0036] Step 2, then mix the phenyl-POSS and the EPDM mixed solution obtained in step 1 according to the mass ratio of POSS:EPDM = 5:95, and stir at a temperature of 40°C for 20 minutes to fully dissolve the POSS and obtain the spinning solution;

[0037] Step 3, and then the spinning solution is placed on the electrospinning equipment for spinning. The various experimental parameters are: applied voltage 22kV, distance from the spinning needle to the receiving device 18cm, spinning solution flow rate 2.5mL / h, spinning The silk collection method is flat plate collection, which is similar to figure 1 , figu...

Embodiment 3

[0039] The concrete steps of preparation are:

[0040] Step 1, first mix the high molecular polymer and the corresponding polymer solvent according to the mass ratio of 5:95, then place it at a temperature of 45°C and stir for 2.5 hours to obtain a mixed solution with a concentration of 5%; the polymer is EPDM, the solvent is tetrahydrofuran;

[0041] Step 2, then mix the phenyl-POSS and the EPDM mixed solution obtained in step 1 according to the mass ratio of POSS:EPDM = 8:92, and stir at a temperature of 45°C for 25 minutes to fully dissolve the POSS and obtain the spinning solution;

[0042] Step 3, and then the spinning solution is placed on the electrospinning equipment for spinning. The various experimental parameters are: applied voltage 25kV, distance from the spinning needle to the receiving device 15cm, spinning solution flow rate 2.0mL / h, spinning The silk collection method is flat plate collection, which is similar to figure 1 , figure 2 shown, and approximate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com