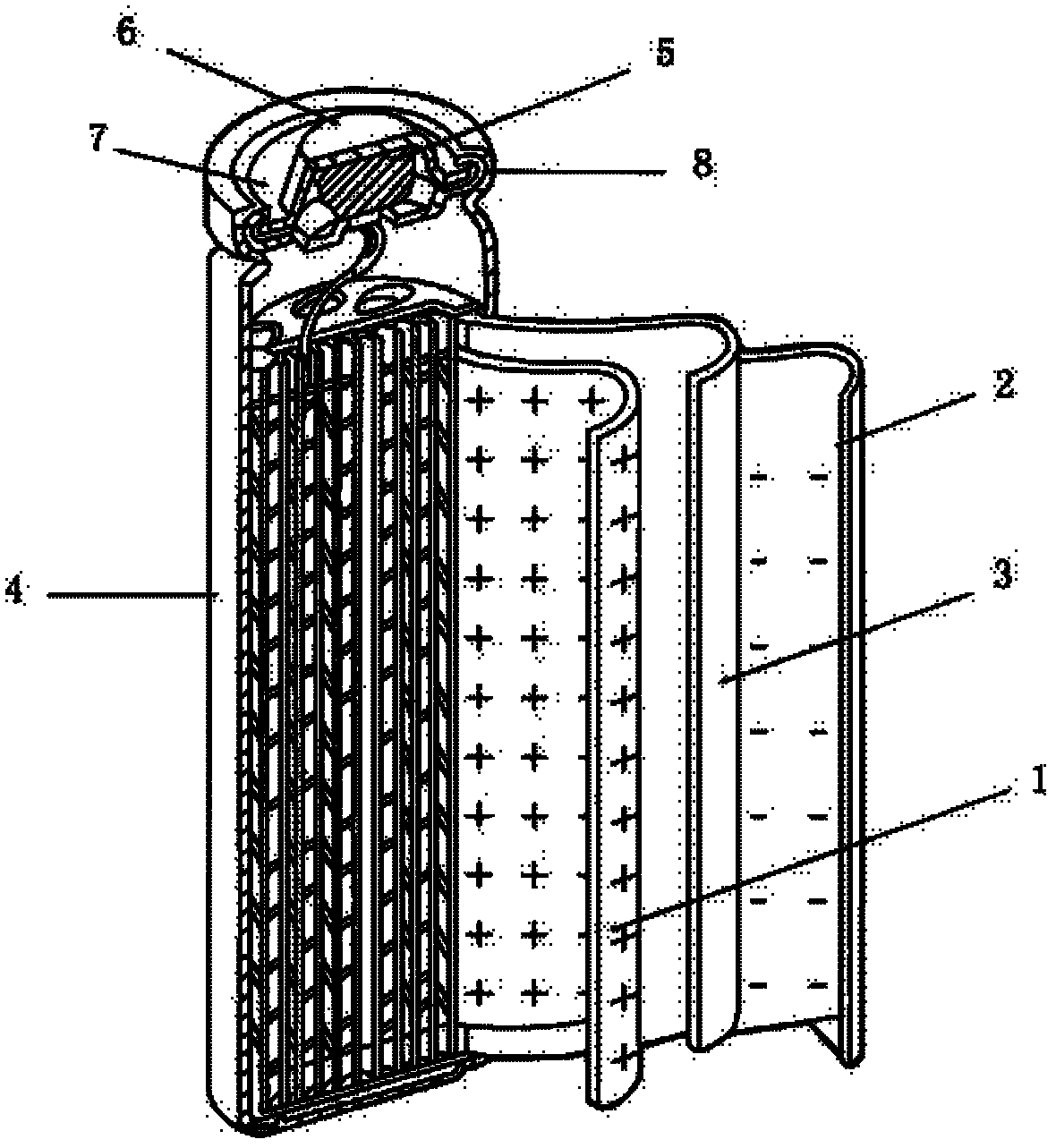

Nickel-hydrogen battery capable of being used in low-temperature environment and preparation method thereof

A nickel-metal hydride battery, low-temperature environment technology, applied in the manufacture of nickel batteries, alkaline batteries, battery electrodes, etc., can solve problems such as unfavorable discharge and unfavorable charging, and achieve good cycle life and power performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

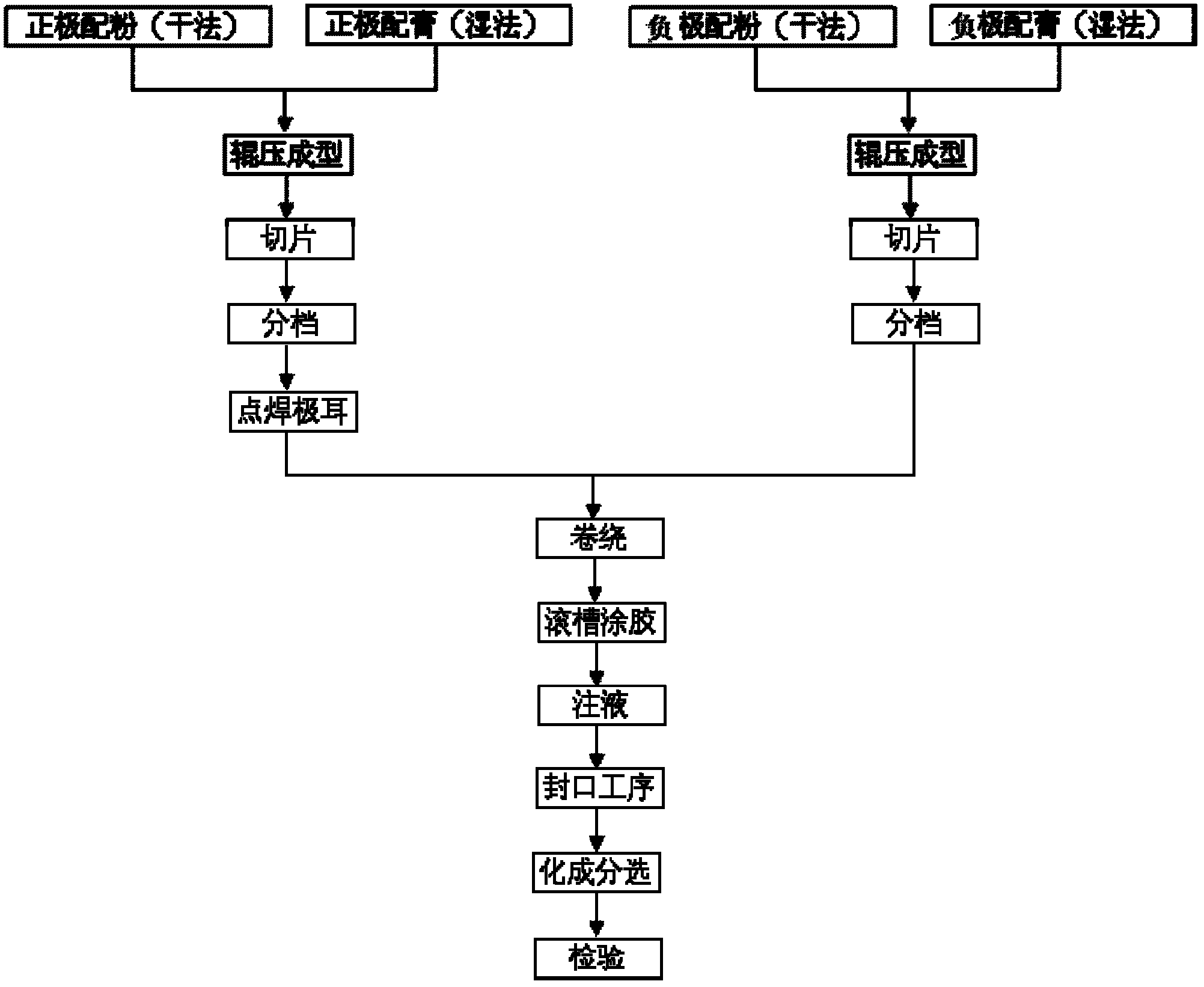

[0027] Such as figure 2 Shown, a kind of preparation method of the Ni-MH battery that can be used in low temperature environment comprises the following steps:

[0028] A, make the positive electrode sheet and the negative electrode sheet; wherein the negative electrode sheet is made as follows: cerium-rich or lanthanum-rich hydrogen storage alloy, carboxymethyl cellulose dispersion, and conductive carbon black dispersion in a mass ratio of 100:12~18:13~ 19.5 Mixing, after fully stirring, mix it into a paste slurry, fill it into the gap of the conductive skeleton of the nickel-plated steel strip by coating, dry it, roll it into a sheet, and cut it into a negative electrode sheet that meets the specifications ;

[0029] B. The position of the positive electrode for spot welding the nickel strip is cleared in the middle position in the length direction by ultrasonic waves, and the nickel strip is spot-welded with the cap in the subsequent assembly as the lead-out end of the po...

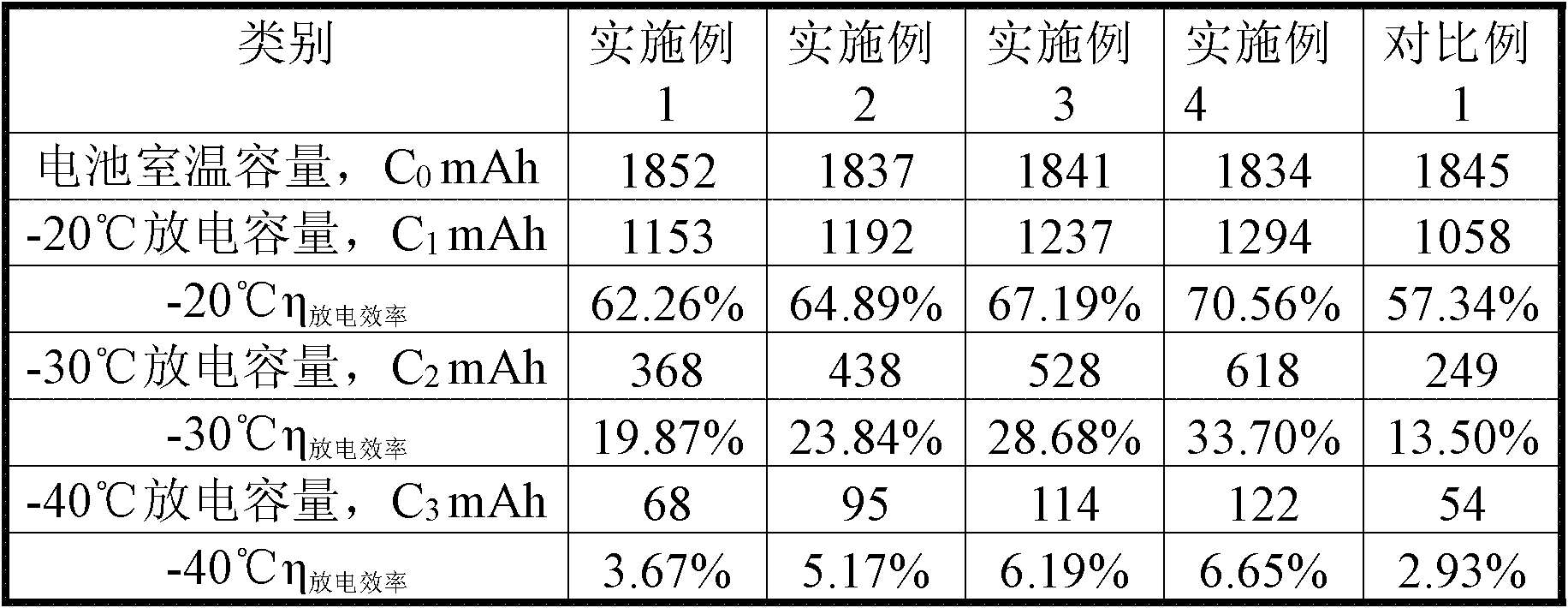

Embodiment 1

[0036] Embodiment 1: Adopt the present invention to make 1.2VAA1800mAh battery and test at low temperature. The production of the positive electrode sheet: ordinary spherical Ni(OH) 2 100 parts, CoO 4 parts, Ca(OH) 21 part, 2 parts of ZnO, add 1 part of polytetrafluoroethylene emulsion (containing 60% polytetrafluoroethylene), mix well in the mortar, then pass through 150 mesh sieve twice, and then fill it into the foamed nickel matrix , rolled into a sheet, and cut into a positive electrode sheet of 80.0 mm long x 38.0 m wide x 0.81 thick. The making of negative plate: 100 parts of ordinary lanthanum-rich hydrogen storage alloys, 12 parts of carboxymethyl cellulose dispersions (containing 2.75% carboxymethyl cellulose), 13 parts of conductive carbon black dispersions (containing 4.6% carbon black solids) Components) after being fully stirred and mixed into a paste slurry, fill it into the gap of the 0.04mm thick nickel-plated steel strip conductive skeleton by coating, dry,...

Embodiment 2

[0037] Embodiment 2: Adopt the present invention to make 1.2VAA1800mAh battery and test at low temperature. The production of the positive electrode sheet: ordinary spherical Ni(OH) 2 100 parts, CoO 5 parts, Ca(OH) 2 1 part, 2 parts of ZnO, add 1 part of polytetrafluoroethylene emulsion (containing 60% polytetrafluoroethylene), after mixing uniformly in a mortar, then pass through a 150 mesh sieve twice, and then fill it into the foamed nickel matrix, It was rolled into a sheet, and cut into a positive electrode sheet with a size of 80.0 mm long×38.0 m wide×0.81 thick. The making of negative plate: 100 parts of ordinary lanthanum-rich hydrogen storage alloys, 12 parts of carboxymethyl cellulose dispersions (containing 2.75% carboxymethyl cellulose), 13 parts of conductive carbon black dispersions (containing 4.6% carbon black solids) Components) after being fully stirred and mixed into a paste slurry, fill it into the gap of the 0.04mm thick nickel-plated steel strip conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com