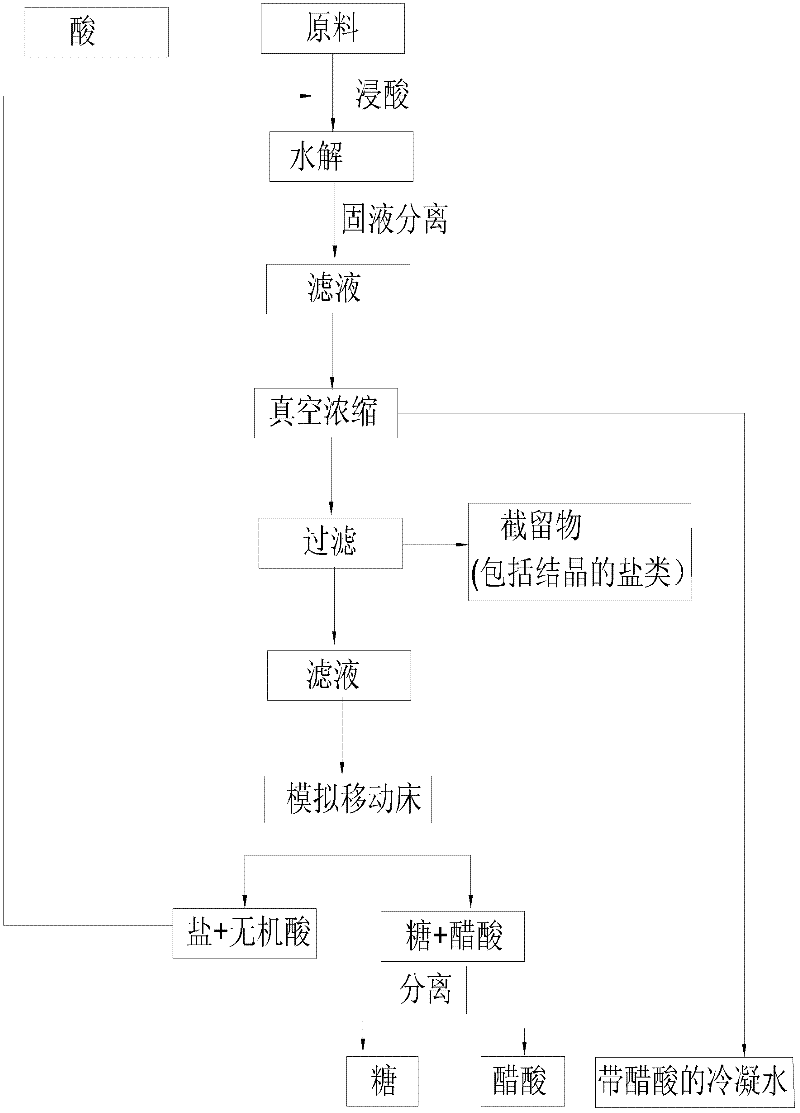

Method for separating sugar, acid and salt of lignocellulose hydrolysate

A technology of lignocellulose and hydrolyzate, applied in the chemical industry, can solve problems such as incomplete separation of sugar and acid, and achieve the effect of saving fermentation cost and simple and convenient recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Put 125Kg of air-dried corncobs in a volume of 1M 3 In the hydrolysis tank, add 1.2% sulfuric acid solution to soak the material surface (acid liquid about 700Kg) and overflow from the top overflow pipe, close the overflow pipe outlet, make the pressure in the tank rise to 0.2Mpa, and maintain 1h, then from Drain the free acid from the bottom. The acid solution actually absorbed by the corn cob material in the pickling process is about 240Kg. After the acid liquid is drained, the hydrolysis kettle is directly fed with steam to be heated in the hydrolysis kettle. Under the condition of 0.2Mpa steam, the pressure is maintained for 1.5h, and the pressure is released instantly to spray out the material. The total weight of the sprayed material is 425kg, and the filtrate is squeezed to obtain 250kg. The residue is soaked with 130kg of water, squeezed again and 140kg of filtrate is collected. The two filtrates combined were 390kg in total, with a soluble solid content of 13...

Embodiment 2

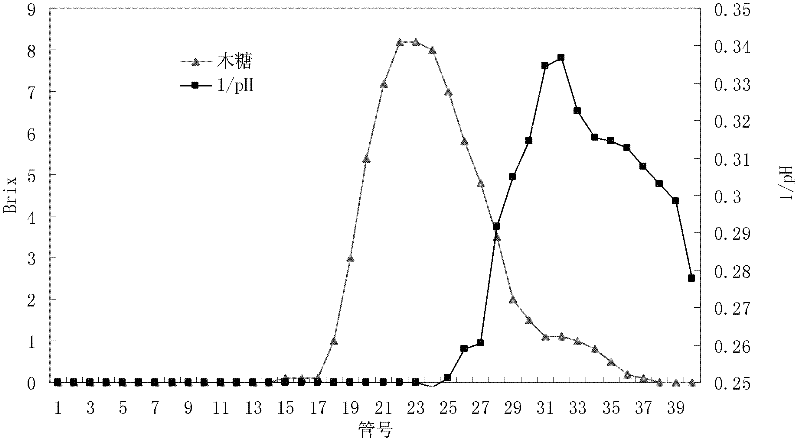

[0060] Air-dried bagasse 90Kg, the loading volume is 1M 3 Carry out pickling treatment in the hydrolysis still, acid solution concentration, pickling treatment condition, hydrolysis condition are all with embodiment 1. During the pickling process, the bagasse actually absorbs about 270kg of acid solution, and the total weight of the sprayed material after hydrolysis is 330kg. Press filter the material to collect the hydrolyzate, add water to the residue to soak the surface of the material again, press again and collect the hydrolyzate. The combined hydrolyzate collected by pressing twice is 450Kg in total, the total solid content of this hydrolyzate is 7%, and the xylose content is about 30g / kg.

Embodiment 3

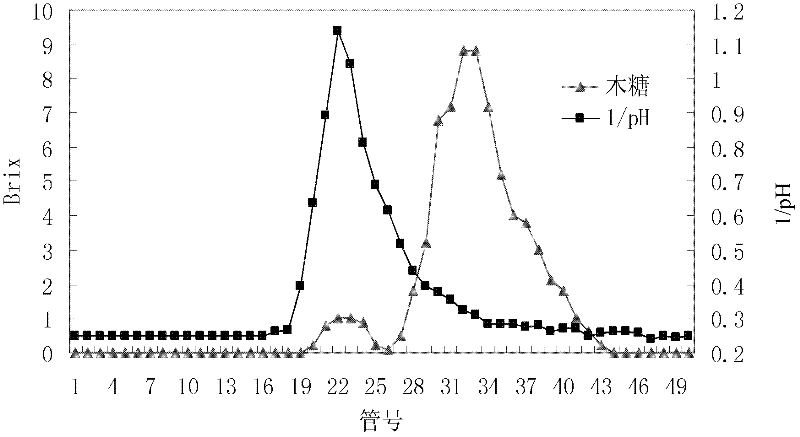

[0062] Prepared according to the conditions of Example 1, 1500Kg of corn cob dilute sulfuric acid hydrolyzate with 12% soluble content was concentrated to a total solid concentration of 45% under vacuum conditions of -0.09Mpa, and the evaporative condensate was collected; the concentrate was filtered to remove insolubles, to obtain Clarified concentrated hydrolyzate 350Kg. The concentrated hydrolyzate of corn cob contains about 350g / kg xylose, 48g / kg sulfate, and 10g / kg acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com