Catalyst for aldol condensation reaction and preparation method thereof

A catalyst and straight-chain aldehyde technology, applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve problems such as low selectivity and complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

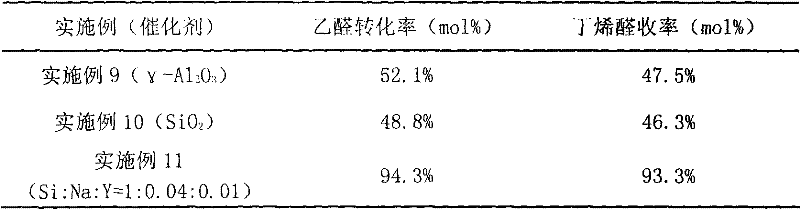

Examples

Embodiment 1

[0017] This example mainly relates to the use of a fixed-bed reactor to evaluate the catalyst carrier for the gas-phase cross-aldol condensation reaction of formaldehyde and acetaldehyde to prepare acrolein. The fixed bed reactor is divided into two sections, the first section is the preheating section, and the second section is the reaction section. The reactor in the preheating section is filled with inert glass balls, the purpose of which is to fully vaporize the added raw material liquid into a gas phase state. In order to make the vaporized raw materials easy to flow, an inert gas such as N 2 To carry vaporized raw materials. The gas after the reaction contains unreacted raw materials and the target product acrolein, as well as the inert gas nitrogen, and the gas flow is cooled and collected by a cold trap to obtain a mixed product. The results were analyzed by gas chromatography.

[0018] First, use the fixed bed reactor to evaluate the activity of the carrier, bake t...

Embodiment 2

[0021] The catalyst prepared in this embodiment, the carrier is activated alumina, no alkali metal or alkaline earth metal element is added, only a small amount of rare earth metal element La is added, and the molar ratio of the components is Al:La=1:0.01, its preparation Methods as below:

[0022] The carrier activated alumina treatment method is the same as that described in Example 1. Weigh 2.17g of lanthanum nitrate hexahydrate in beaker A, add 60ml of deionized water and stir until completely dissolved to obtain solution I; then weigh 61.00g of the previously dried activated alumina particles and place them in beaker B, add solution I In the beaker B, stir while adding, place it for impregnation after the addition, evaporate the excess water after 24.0h, take out the catalyst, bake in an oven at 110°C for 12.0h, and then place the above catalyst in a dry oxygen-containing atmosphere at 600°C for roasting treatment 10.0h, cooled to room temperature that is the desired cat...

Embodiment 3

[0025] The catalyst prepared in this embodiment, its carrier is activated alumina, the active component is Li element, no rare earth metal element is added, and the molar ratio of the components is Al:Li=1:0.04, and its preparation method is as follows:

[0026] The carrier activated alumina treatment method is the same as that described in Example 1. Weigh 1.38g of lithium nitrate in a 100ml beaker A, add 60ml of deionized water to dissolve to obtain solution I, then weigh 61.00g of the previously dried activated alumina particles and place them in beaker B, add solution I to beaker B, Stir while adding, place it for impregnation after adding, evaporate the excess water after 24.0h, take out the catalyst, bake in an oven at 110°C for 12.0h, then put the above catalyst in a dry oxygen-containing atmosphere at 600°C for 10.0h, cool to the desired catalyst at room temperature.

[0027] The method in Example 1 was used to evaluate the catalyst of this example. As a result, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com