Preparation method of nanoscale carbon-loaded metallic copper catalyst

A carbon-supported and catalyst technology is applied in the field of preparation of nano-scale carbon-supported metal copper catalyst, which can solve the problems of low impurity ash content, low mechanical strength, low production cost, complicated process, etc., and achieves good product stability and anti-caking performance. , the data is accurate and accurate, the effect of rich material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

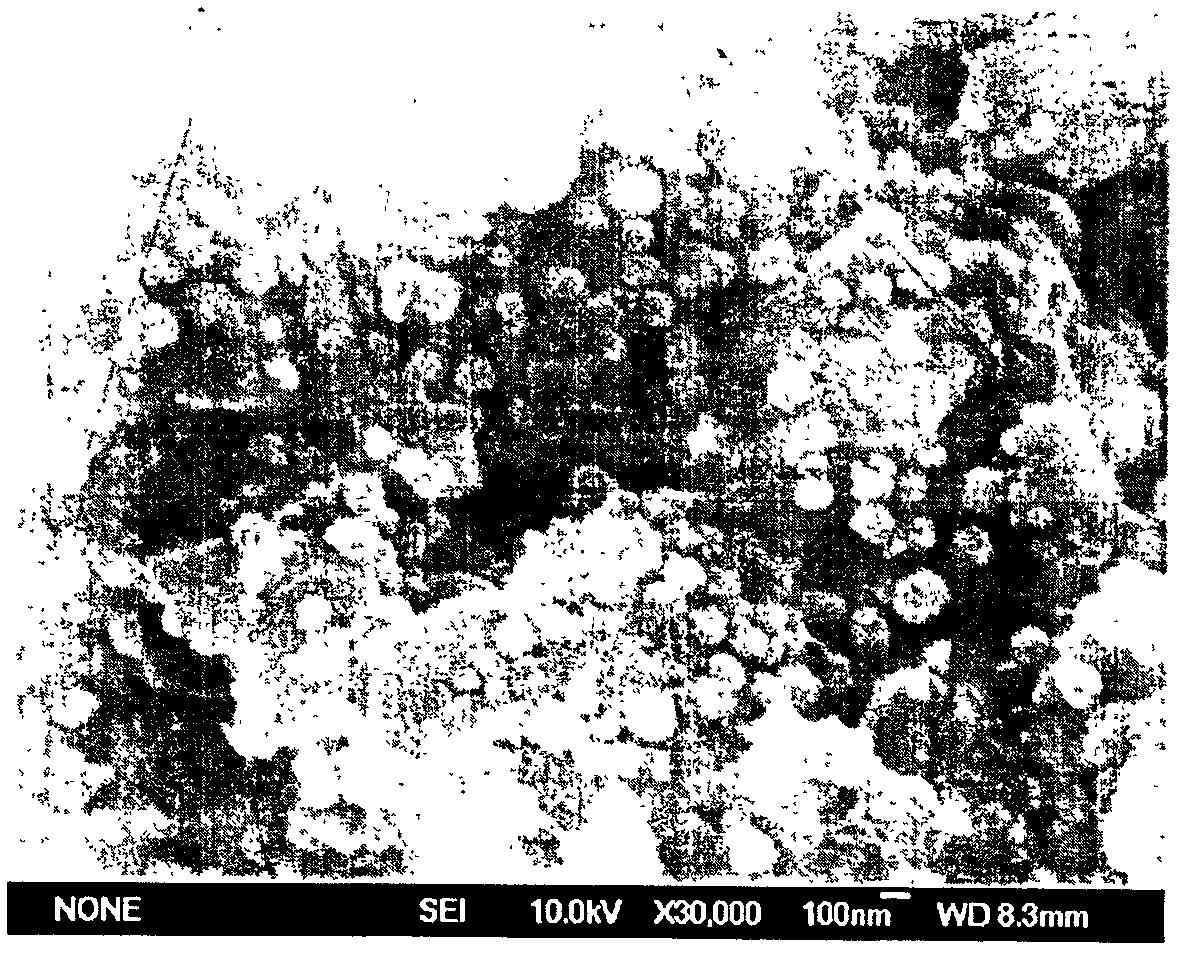

[0073] The performance measurement method of carbon-supported metal copper catalyst is as follows:

[0074] Analyzer: GC-950 gas chromatograph from Shanghai Haixin Chromatography Co., Ltd., hydrogen flame detector, carrier gas Ar, capillary column is Agilent DB-5, column inner diameter 0.35mm, column length 30m, mainly analyzes the Methanol, dimethyl carbonate, methyl formate, dimethoxymethane;

[0075] The gas-phase oxidative carbonylation reaction of methanol is carried out in a high-pressure continuous fixed-bed miniature stainless steel tube reactor (φ6mm×L450mm). Methanol is introduced by a micro-injection pump, and then carbon monoxide and oxygen gas are mixed into the gasification chamber, and after being mixed in the vaporization chamber Enter the reactor, flow through the catalyst bed, and the product flows out from the bottom and is condensed by a cold trap to obtain a liquid phase product; the volume ratio of carbon monoxide and oxygen in the raw gas is 11:1, the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com