Preparation method of propyldicyclohexyl bromide

A technology of propyl bicyclohexyl and cyclohexyl ketone, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of high processing cost, high risk index, burning effect, etc., to reduce pollution, The effect of improving safety factor and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

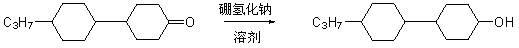

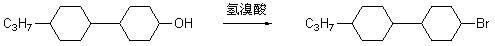

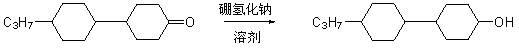

Method used

Image

Examples

Embodiment 1

[0023] Add 27.8mol of water and 0.26mol (0.5eq) of sodium borohydride into a 1000ml three-necked reaction flask. After the sodium borohydride is completely dissolved under stirring, slowly add 0.518mol (1.0eq) of propylbicyclohexyl dropwise at room temperature, and then Carry out the reaction at 20°C, and when the reaction system shows more white powder, spot the plate to confirm whether there is any raw material, if there is no, it means that the reaction is complete. After the reaction product was filtered by suction, it was washed with saturated sodium bicarbonate solution, and then washed with water for 3 to 4 times, drained and dried to obtain 0.58 mol of propyl bicyclohexyl alcohol with a water content of 16%, and the yield was greater than 95%. %, for the next bromination reaction. Set up a mechanical stirring device, add 0.067mol (1.0eq) of the above-mentioned propyl bicyclohexyl alcohol into a 250ml three-necked flask, and then add 0.67mol (10eq) of hydrobromic acid t...

Embodiment 2

[0025] Add 8.87mol of ethanol and 0.518mol (1.0eq) of sodium borohydride into a 1000ml three-necked reaction flask. After the sodium borohydride is completely dissolved under stirring, add 0.518mol (1.0eq) of propyl bicyclohexyl ketone dropwise at room temperature, slowly drop Add, let it react at 10°C after the dropwise addition is complete. When the reaction system appears more white powder, spot the board to confirm whether there are raw materials, if there is no, it means that the reaction is complete. After the reaction product was filtered by suction, it was washed with saturated sodium bicarbonate solution, and then washed with clear water for 3 to 4 times, drained and dried to obtain 0.473 mol of propyl bicyclohexyl alcohol with a water content of 20%, and the yield was greater than 92 %. Set up a mechanical stirring device, add 0.067mol (1.0eq) of the above-mentioned propyl bicyclohexyl alcohol into a 250ml three-necked flask, then add 0.335mol (5eq) of HBr into the ...

Embodiment 3

[0027] Add 12.3mol of methanol and 0.78mol (1.5eq) of sodium borohydride into a 1000ml three-necked reaction flask. After the sodium borohydride is completely dissolved under stirring conditions, add 0.518mol (1.0eq) of propylbicyclohexyl dropwise at room temperature, slowly drop Add, because heat will be released during the dropwise addition, after the dropwise addition is complete, let it react at 30°C. When the reaction system appears more white powder, spot the board to confirm whether there are raw materials, if there is no, it means that the reaction is complete. After the reaction product was filtered by suction, it was washed with saturated sodium bicarbonate solution, and then washed 3 to 4 times with clear water, and then dried and air-dried to obtain 0.58 mol of propyl bicyclohexyl alcohol with a water content of 18%, and the yield was greater than 91 %. Set up a mechanical stirring device, add 0.067mol (1.0eq) of the above-mentioned propyl bicyclohexyl alcohol int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com