Method for preparing alginic acid and sodium alginate through air steam explosion coupling biological compound enzyme technology

A technology of biological compound enzyme and sodium alginate, which is applied in the field of modernization of traditional Chinese medicine, can solve the problems of low molecular weight of alginic acid, destroy effective substances, reduce product quality, etc., so as to improve product yield and product quality, reduce interference, and reduce production capacity. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

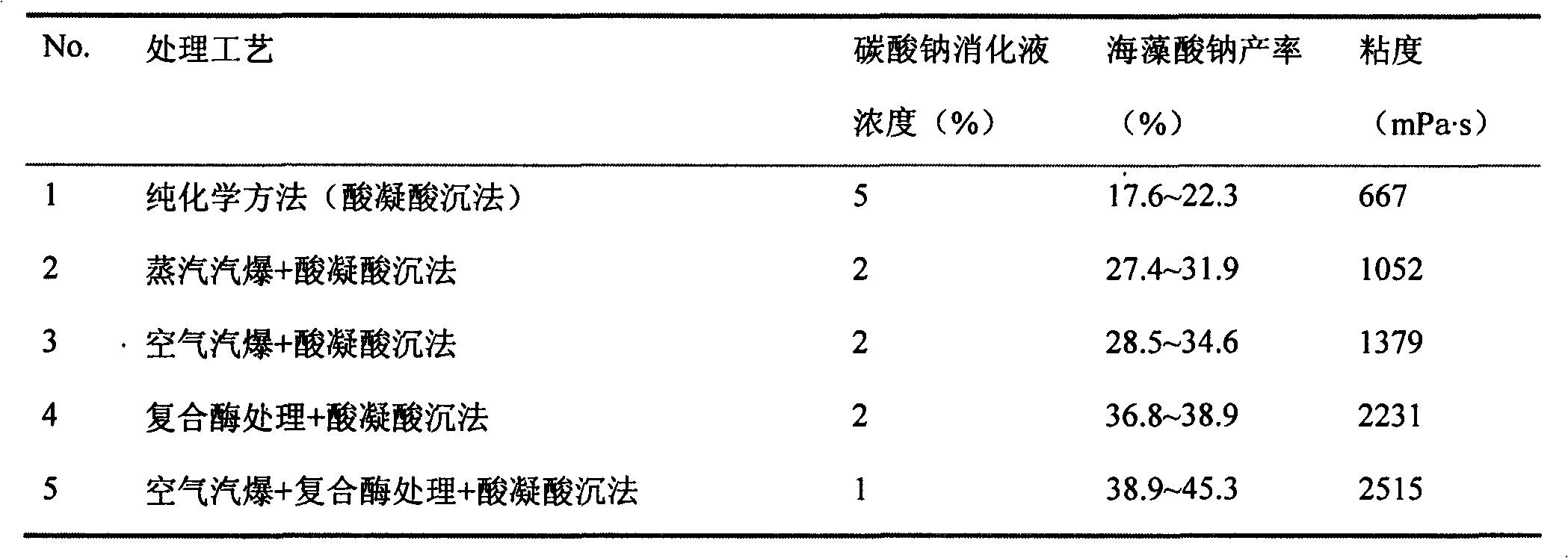

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Pre-treatment of raw materials: soak dried kelp in water for 1 hour to soften, wash to remove impurities such as sediment, cut into 5-15cm sections, and drench off the surface moisture;

[0032] (2) Air steam explosion treatment: place the kelp through the raw material pretreatment in the steam explosion tank, use air as the steam explosion medium, make the pressure in the blasting device 1.0MPa, and the blasting time is 5min;

[0033] (3) Biological compound enzyme treatment: suspend the kelp after the air explosion with 10 times the amount of water, add a biological compound enzyme preparation equivalent to 0.5% of the raw material mass (mass ratio: 15% cellulase, 20% acid protease, fruit Gluease 15%, α-amylase 15%, xylanase 20%, laccase 10%, mannanase 5%), hydrolyze at pH 5.5, 50°C for 3 hours;

[0034] (4) Digestion: add 1.0% aqueous sodium carbonate solution equivalent to 10 times the amount of raw materials to the system obtained through (3), and digest at 60°C ...

Embodiment 2

[0038] (1) Raw material pre-treatment: wash the fresh kelp with water to remove impurities such as sediment, cut it into 5-15cm sections, and drench off the surface moisture;

[0039] (2) Air steam explosion treatment: place the kelp through the raw material pretreatment in the steam explosion tank, use air as the steam explosion medium, make the pressure in the blasting device 1.5MPa, and the blasting time is 15min;

[0040] (3) Biological compound enzyme treatment: Suspend the kelp after air explosion with 10 times the amount of water, add biological compound enzyme preparation equivalent to 0.5% of raw material quality (mass ratio: 20% cellulase, 20% acid protease, fruit Gluease 10%, α-amylase 10%, xylanase 20%, laccase 15%, mannanase 5%), hydrolyze at pH 6 and 60°C for 2 hours;

[0041] (4) Digestion: add 0.5% aqueous sodium carbonate solution equivalent to 10 times the amount of raw materials to the system obtained after the treatment in (3), and digest at 40° C. for 1.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com