Preparation method of polystyrene-b-polybutadiene segmented copolymer nanometer latex

A polybutadiene block and polystyrene technology, applied in the field of polymers, can solve the problems of limiting the application of SBS, inability to introduce polar groups in situ, etc., and achieve the effects of large molecular weight, low pollution and high polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of polystyrene-b-polybutadiene block copolymer nano latex of the present invention comprises the steps:

[0019] Add 0.5-10 parts by weight of amphiphilic macromolecular emulsifier to 40-100 parts by weight of water to form a water phase; mix 5-20 parts by weight of styrene and 0.02-1 part by weight of a reversible addition-fragmentation chain transfer reagent , to form an oil phase; after fully mixing the water phase and the oil phase, move it into the reactor, pass nitrogen gas and exhaust oxygen for 30-60 minutes while stirring, heat up to 50-80°C, add 0.005-0.5 parts by weight of the initiator, and initiate polymerization After 10 to 60 minutes, add 0.05 to 1.5 parts by weight of sodium hydroxide, after 0.5 to 5 hours of polymerization, add 1 to 80 parts by weight of butadiene, polymerize for 1 to 15 hours, cool and discharge, add 0.01 to 0.5 parts by weight Terminator hydroquinone.

[0020] The general chemical structure formula of the rever...

Embodiment 1

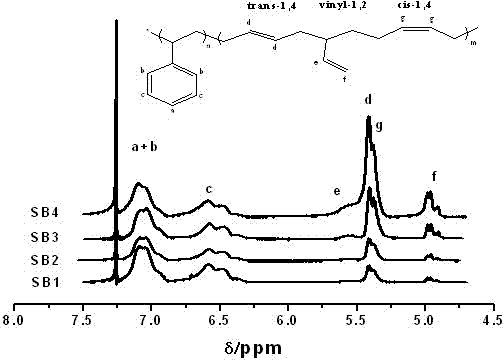

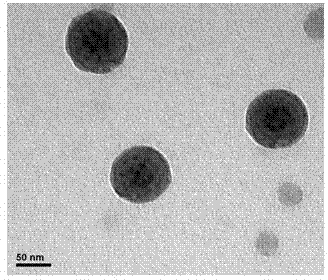

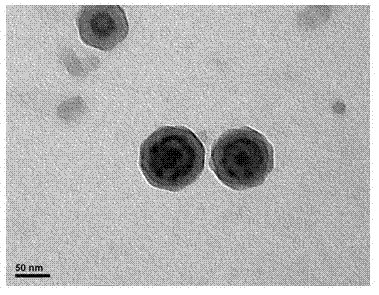

[0034] Add 0.5 parts by weight of amphiphilic macromolecular emulsifier to 40 parts by weight of water to form a water phase; 5 parts by weight of styrene and 0.1 parts by weight of RAFT1 to form an oil phase; after fully mixing the water and oil phases, Move it into the reactor, pass nitrogen gas and exhaust oxygen for 30 minutes while stirring, heat up to 80°C, add 0.01 parts by weight of potassium persulfate, initiate polymerization for 20 minutes, add 0.05 parts by weight of sodium hydroxide, and after polymerization for 1 hour, add 2.5 parts by weight part of butadiene, polymerized for 2 hours, cooled and discharged, and added 0.01 parts by weight of terminator hydroquinone to obtain latex with a block structure, its composition is as follows figure 1 SB1 in the nuclear magnetic spectrum, the polybutadiene in the copolymer has three configurations of cis-1,4 addition, trans-1,4 addition and 1,2 addition, the polybutadiene block The mass fraction is 32%, and the inside of th...

Embodiment 2

[0036] Add 1 part by weight of amphiphilic macromolecular emulsifier to 50 parts by weight of water to form a water phase; mix 10 parts by weight of styrene and 0.2 parts by weight of RAFT2 to form an oil phase; fully mix the water phase and the oil phase , moved into the reactor, passed nitrogen gas and deoxygenated for 60 minutes while stirring, heated up to 70°C, added 0.02 parts by weight of potassium persulfate, initiated polymerization for 30 minutes, added 0.1 parts by weight of sodium hydroxide, and added 8 parts by weight after polymerization for 30 minutes. The butadiene of weight part, polymerize 5 hours, cool discharge, add 0.1 weight part terminator hydroquinone, can obtain the latex with block structure, its composition is as follows figure 1 SB2 in the nuclear magnetic spectrum, the polybutadiene in the copolymer has three configurations: cis-1,4 addition, trans-1,4 addition and 1,2 addition, the polybutadiene block The mass fraction is 42%, and the interior of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com