Electroactive fluorescent polymer, preparation method and use for detecting oxidizing or reducing substance

A fluorescent polymer and electroactive technology, applied in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of limited types of detection objects, pollution, and inability to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 0.9691g (5.015mmol) of 2-aminoanthracene and 2mL of triethylamine into 15mL of tetrahydrofuran, then dissolve 0.8828g (5mmol) of 2,6-difluorobenzoyl chloride in 15mL of tetrahydrofuran, dropwise within 2 hours Add to the above solution system, stir rapidly; after the dropwise addition, continue to react under nitrogen protection for 2 hours, filter with suction, wash the obtained precipitate with dichloromethane to obtain N1 monomer, and then dry it in a vacuum oven at 45°C for 24 hours. The yield was 91%.

Embodiment 2

[0045] Add 0.9089g (5.015mmol) of 2-aminofluorene and 2mL of triethylamine into 15mL of tetrahydrofuran, then dissolve 0.8828g (5mmol) of 2,6-difluorobenzoyl chloride in 15mL of tetrahydrofuran, dropwise within 2 hours Add to the above solution system, stir quickly; after the dropwise addition, continue to react for 2 hours under the protection of nitrogen, filter with suction, wash the obtained precipitate with dichloromethane to obtain N2 monomer, and then dry it in a vacuum oven at 45°C for 24h. The yield was 89%.

Embodiment 3

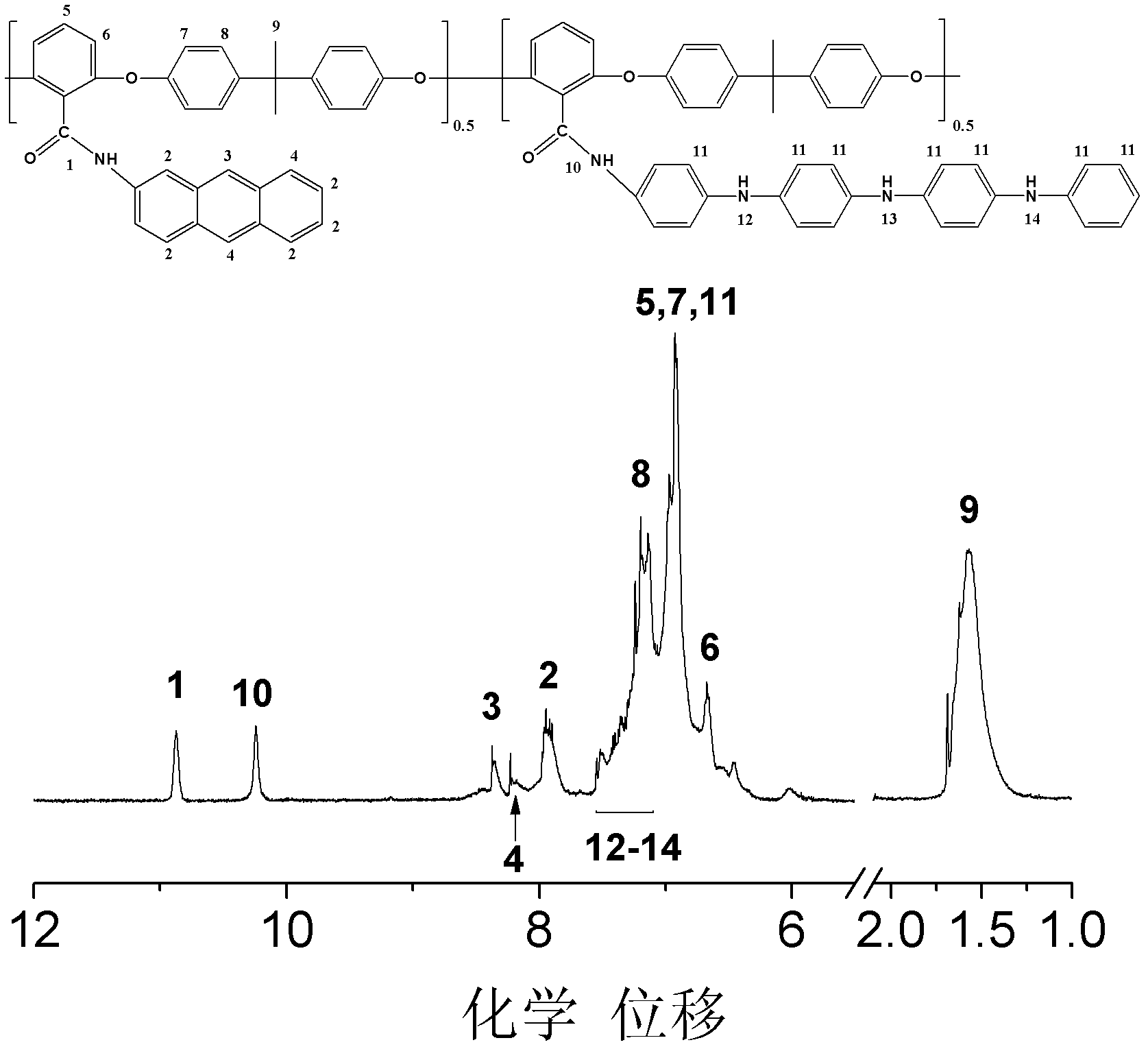

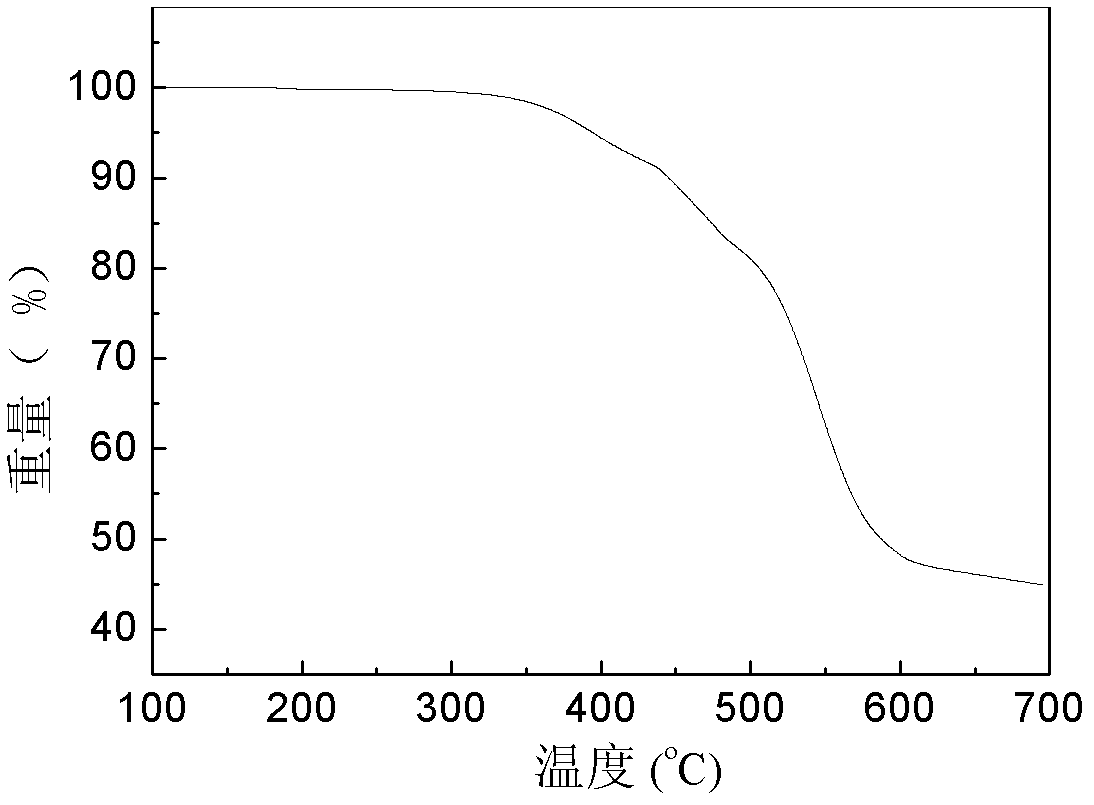

[0047] Difluoromonomer M (1.520g, 3mmol) and bisfluoromonomer N1 (1.041g, 3mmol), bisphenol A (1.370g, 6mmol) were added to a 100mL three- In the neck flask, add 20mL N-methylpyrrolidone (NMP), 10mL toluene, 0.8354g (6.018mmol) anhydrous potassium carbonate, N 2 Protected, heated to 165°C toluene and refluxed water for 2 hours, then distilled the toluene, increased the temperature to 190°C and continued the reaction for 8 hours, stopped heating, and cooled to room temperature. Discharge in 200mL distilled water, and obtain precipitate after filtration. Washed three times each with distilled water and absolute ethanol, and dried under vacuum for 48 hours to obtain a blue-gray powder solid C 1 (PAE-p-OA), yield 87%. The number average molecular weight of the polymer was 33800 (where 15<m<25, 25<n<40), and the molecular weight distribution was 1.79.

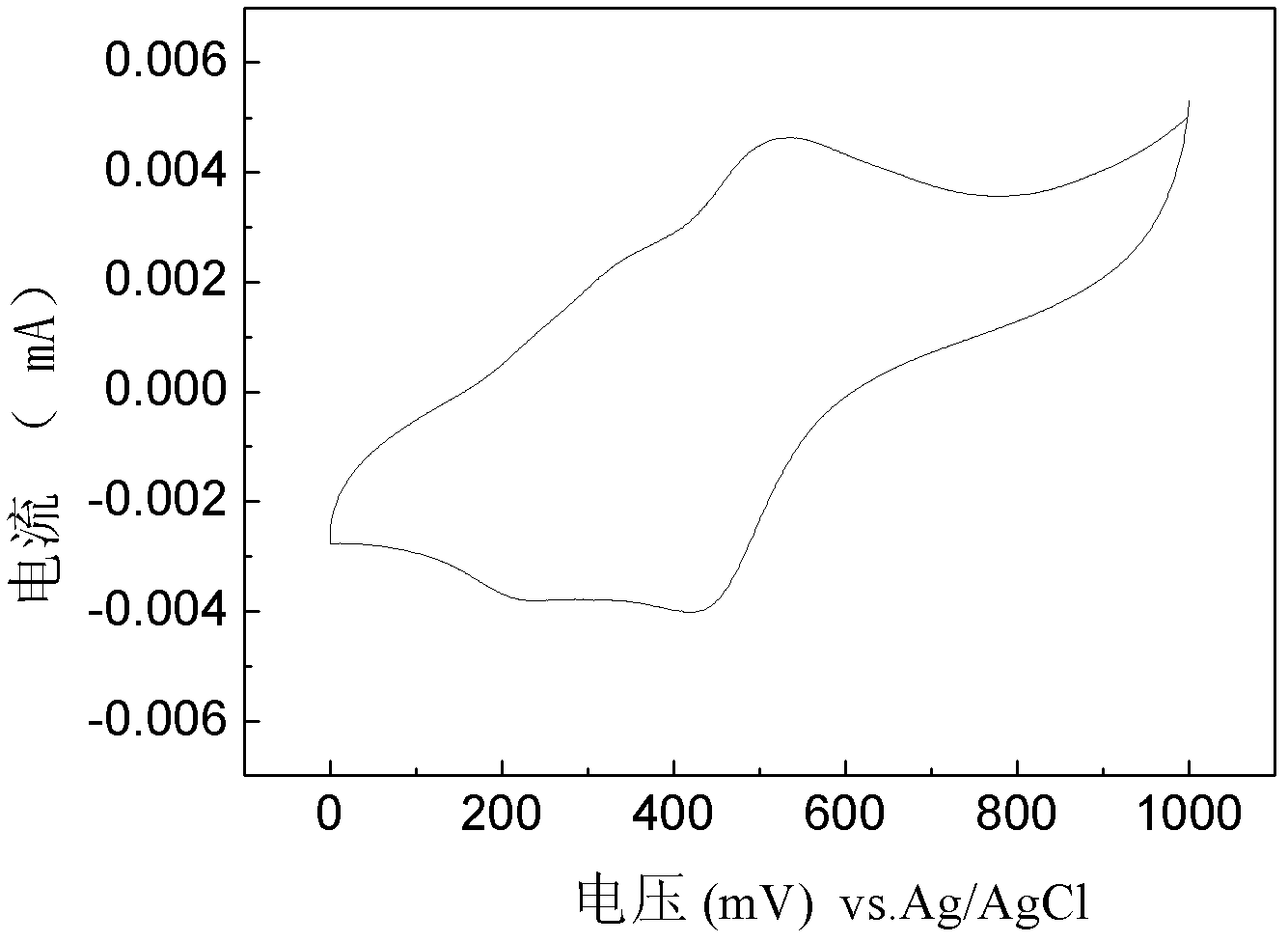

[0048] Polymer C 1 Dubbed two parts with a concentration of 1.0×10 -5 M of DMAc (containing 3vol% H 2 O) solution, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com