Preparation method of chitosan modified polylactic acid material by gamma-ray irradiation

A modification technology of polylactic acid material and chitosan, which is applied in the field of γ-ray irradiation preparation of chitosan modified polylactic acid material, can solve the problem of environmental protection and biodegradation characteristics of polylactic acid material, thermodynamic performance decline, degradation Uncontrollable performance and other problems, to achieve good thermodynamic performance, reduce dosage, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

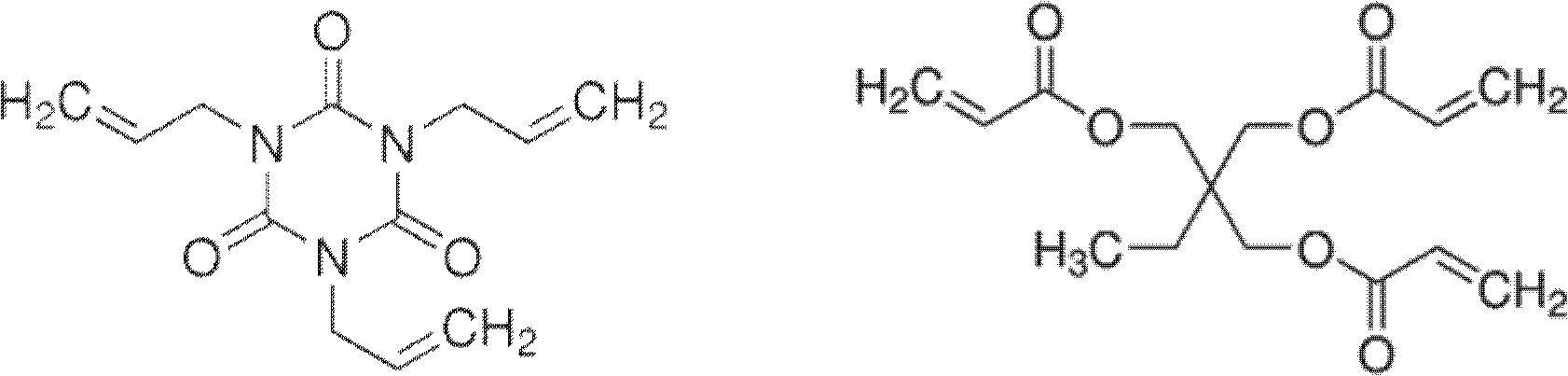

[0019] First put the polylactic acid in a vacuum drying oven at 60°C for 2 hours, weigh 100g of polylactic acid and add 1.5g of chitosan (molecular weight about 4000) and 1.5g of triallyl isocyanurate in sequence, and mix at room temperature; Heat to 190°C, stir for 1 hour, and mix well; pour the mixed melt into a preheated (90°C-120°C) mold, pressurize to 10MPa on a flat vulcanizer, and heat press at 150°C for 30min, keep The above-mentioned pressure is cooled and molded, and demoulded; the obtained material is put into an irradiation bag filled with nitrogen and sealed, and placed in a Co-60 γ-ray irradiation center at room temperature for irradiation treatment, and the γ-ray irradiation dose rate is about 2KGy. h -1 , when the absorbed dose reaches 50KGy, the irradiation bag is taken out to obtain chitosan-modified polylactic acid material.

[0020] The test results of the samples show that the gel fraction of the chitosan-modified polylactic acid material is 83%, the glas...

Embodiment 2

[0022] First put the polylactic acid in a vacuum drying oven at 60°C to dry for 2 hours, weigh 100g of polylactic acid and add 2.5g of chitosan (molecular weight about 4000) and 2.5g of triallyl isocyanurate in sequence, and mix at room temperature; Heat to 190°C, stir for 1 hour, and mix well; pour the mixed melt into a preheated (90°C-120°C) mold, pressurize to 10MPa on a flat vulcanizer, and heat press at 150°C for 30min, keep The above-mentioned pressure is cooled and molded, and demoulded; the obtained material is put into an irradiation bag filled with nitrogen and sealed, and placed in a Co-60 γ-ray irradiation center at room temperature for irradiation treatment, and the γ-ray irradiation dose rate is about 2KGy. h -1 , when the absorbed dose reaches 40KGy, the irradiation bag is taken out, and the chitosan-modified polylactic acid material is obtained.

[0023] The test results of the samples show that the polylactic acid material modified by chitosan after γ-ray irr...

Embodiment 3

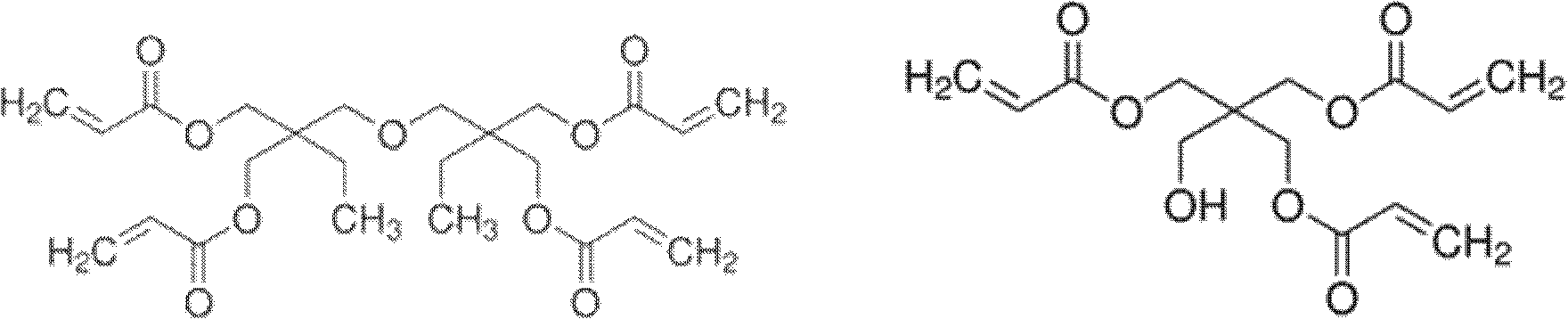

[0025] First put the polylactic acid in a vacuum drying oven at 60° C. for 2 hours, weigh 100 g of polylactic acid and add chitosan (molecular weight 10 3 ~10 5 ,) 0.5g, trimethylolpropane triacrylate 0.5g, mix at room temperature; heat the above mixture to 240°C, stir for 2h, mix well; pour the mixed melt into preheated (90°C-120°C) In the mold, pressurize to 10MPa in stages on a flat vulcanizer, hot press at 180°C for 1h, keep the above pressure to cool and form, and demould; put the obtained material into an irradiation bag, seal it, and then vacuumize it (vacuum degree-0.09MPa ), put it into the Co-60 gamma ray irradiation center for irradiation treatment at room temperature, and the gamma ray irradiation dose rate is about 10KGy h -1 , when the absorbed dose reaches 150KGy, the irradiation bag is taken out to obtain chitosan-modified polylactic acid material.

[0026] The test results of samples show that the polylactic acid material modified by chitosan after γ-ray irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com