Low-cost high-flame-retardant reinforced polyamide and preparation method for same

A technology of high flame retardant and polyamide, which is applied in the field of low-cost high flame retardant reinforced polyamide and its preparation, can solve the problems of difficulty in reducing the cost of flame retardant materials and rising prices, and achieve excellent mechanical properties, reduced dosage, and good surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope described in the examples.

[0030] The raw materials adopted in the following examples 1-5 are respectively:

[0031] The nylon resin is polycaprolactam PA6 YH700 from Yueyang Petrochemical.

[0032] The main flame retardant is Nantong Chemical America Albemarle BPS621.

[0033] The first flame retardant synergist is a stannate composite flame retardant.

[0034] The first flame retardant synergist is ultrafine magnesium silicate LX-999.

[0035] The glass fiber is Taishan long glass fiber T635B.

[0036] The toughening and solubilizing agent is POE-g-MAH.

[0037] Antioxidant is 1098,168.

[0038] The lubricant is zinc stearate, TAF.

[0039] The nucleating agent is long-chain carboxylic acid calcium salt CAV102.

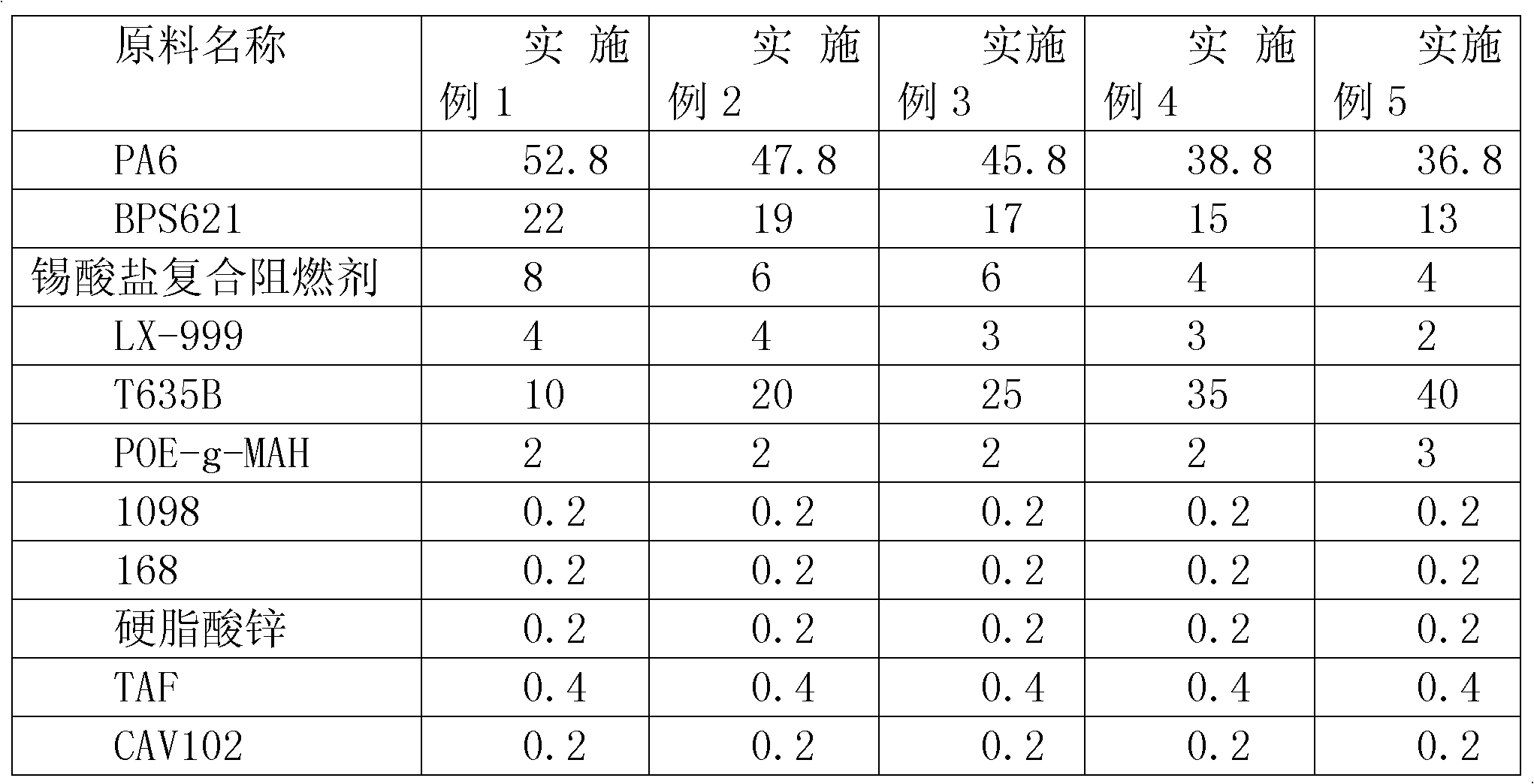

[0040] The proportioning in embodiment 1-5 is as shown in table 1.

[0041] During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com