Novel high-consumption resistant multi-element rare earth tungsten electrode and preparation method thereof

A new technology of rare earth tungsten, which is applied in the field of tungsten electrode materials and its preparation, can solve the problems of difficult processing of high-content rare earth tungsten materials and low yield, and achieve the effects of shortening sintering time, improving product yield, and simplifying equipment and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

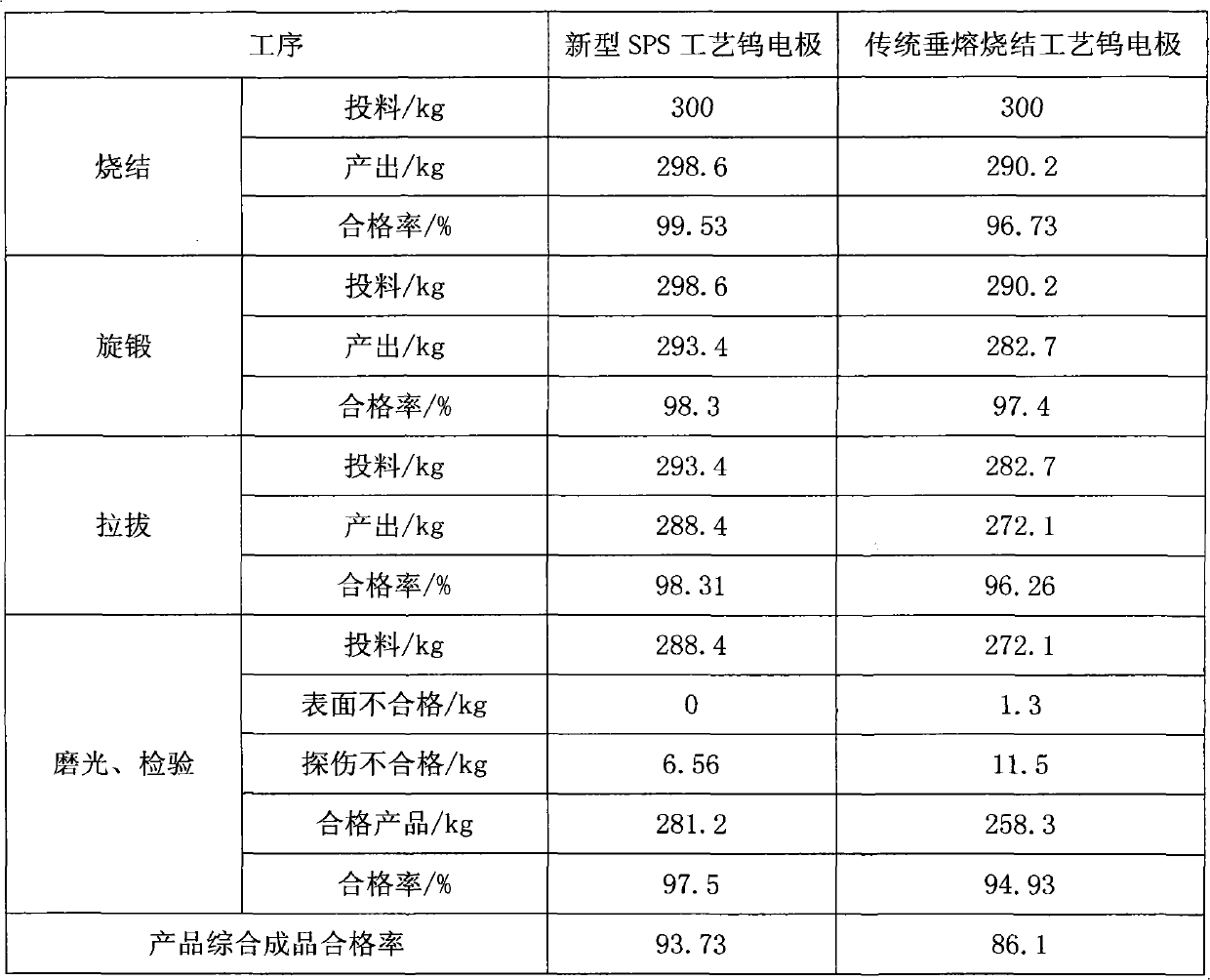

[0018] The present invention will be further described below in conjunction with the technical scheme of the present invention and the traditional process method.

[0019] In a new type of high-durability multi-component rare earth tungsten electrode, the weight ratio of rare earth is Re 2 o 3 : La 2 o 3 : CEO 2 : Y 2 o 3 = 1:2:2:6, the other is W, and the composite rare earth tungsten electrode with a total content of 2.2% is studied through the SPS preparation process, and compared with the traditional "pressing + vertical melting sintering" process, the specific content is as follows:

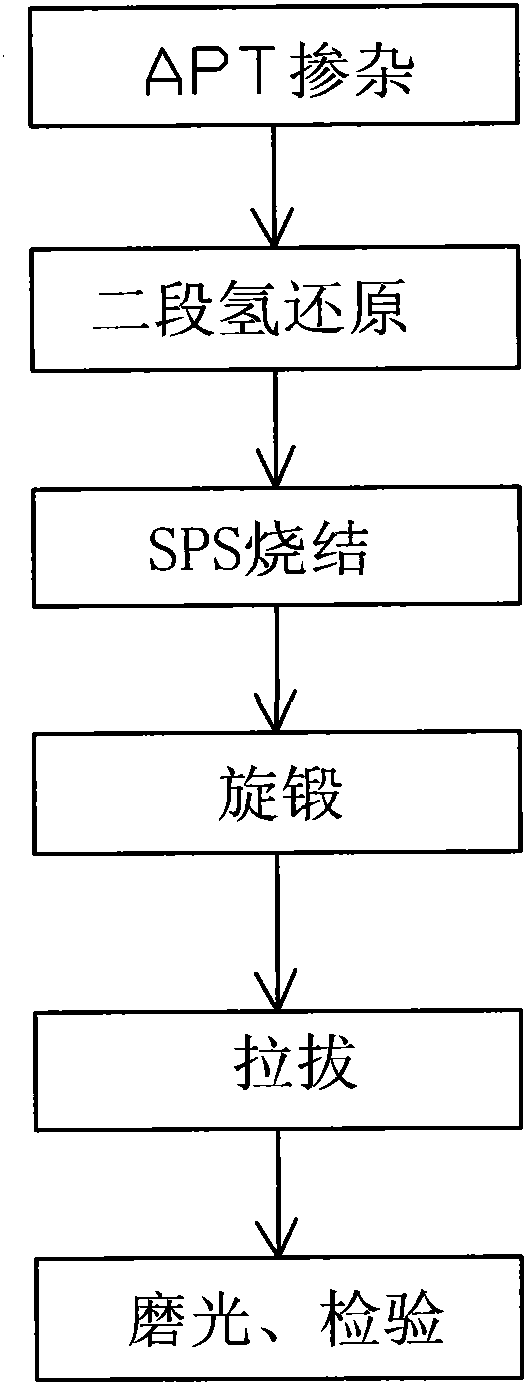

[0020] Such as figure 1 , described in the process flow chart of the present invention: the invention includes the following steps: 1. Doping, 2. Reduction, 3SPS sintering, 4 swaging, 5 drawing, 6 polishing, and inspection.

[0021] Wherein, in the doping step, a liquid-solid doping method is adopted. Make a solution of rare earth nitrate and deionized water, put a certain weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com