Anti-freezing solution regenerating and recovering device used for refrigerating air-conditioning system

A technology of heat recovery device and antifreeze solution, which is applied in air conditioning system, heat recovery system, household heating, etc., and can solve problems such as expansion and cracking of evaporative condenser components, freezing of refrigerant into ice, and huge solution storage space, etc. , to avoid freezing, increase the evaporation temperature, and increase the concentration of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

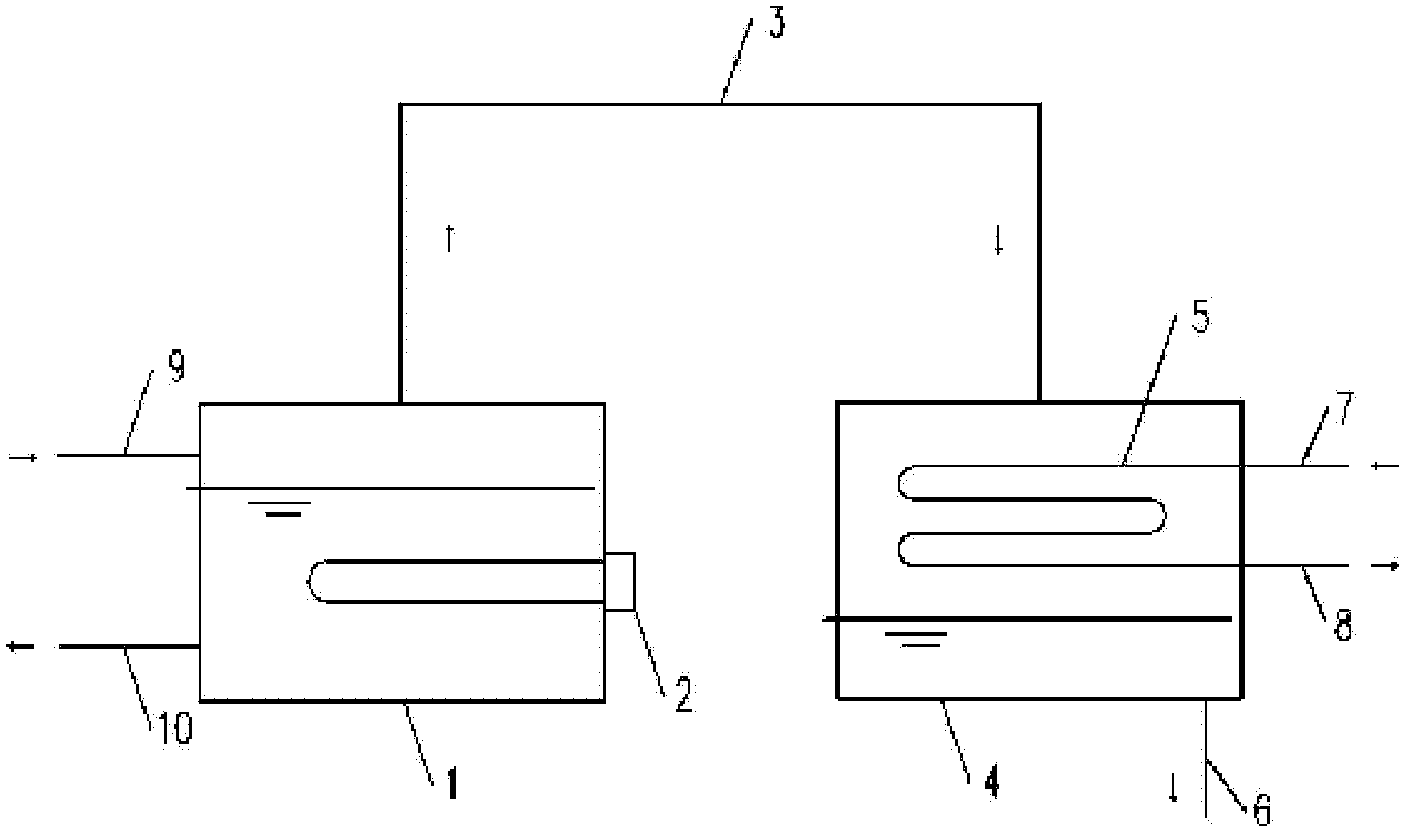

Embodiment 1

[0041] This embodiment is a kind of antifreeze solution regeneration heat recovery device for refrigeration and air conditioning system, such as figure 1 As shown, it includes a regeneration container 1 and a water vapor condensation heat recovery device 4, and the regeneration container and the water vapor condensation heat recovery device are connected through a water vapor channel 3; A low-concentration antifreeze solution channel 9 and a high-concentration antifreeze solution channel 10; a first heat exchanger 5 is provided in the water vapor condensation heat recovery device, and a heat exchange medium inlet 7 and a heat exchange medium outlet 8 are respectively provided on the first heat exchanger , The water vapor condensation heat recovery device is provided with a condensed water outlet 6 .

[0042] Wherein, the heat exchange medium inlet is the inlet of heating circulating water, refrigerant or antifreeze solution, and the heat exchange medium outlet is corresponding...

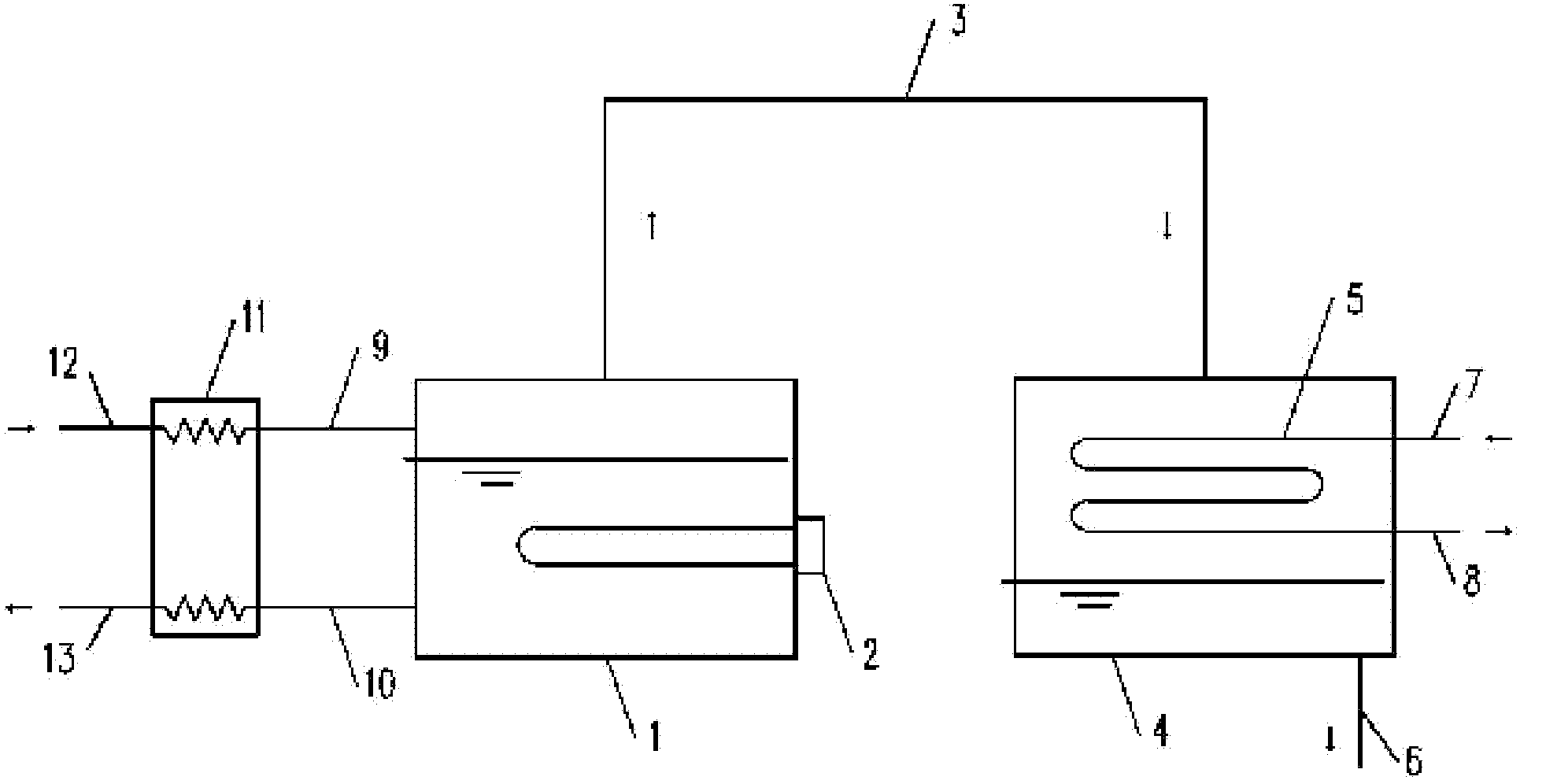

Embodiment 2

[0046] This embodiment is as a kind of improved scheme of embodiment 1, as figure 2 As shown, compared with Example 1, the difference is that the antifreeze solution regeneration heat recovery device also includes a second heat exchanger 11, and the second heat exchanger 11 is provided with a low-concentration solution inlet 12 and a high-concentration solution outlet 13. The low-concentration antifreeze solution channel 9 passes through the second heat exchanger 11 and communicates with the low-concentration solution inlet 12 , and the high-concentration antifreeze solution channel 10 passes through the second heat exchanger 11 and communicates with the high-concentration solution outlet 13 . The low-concentration antifreeze solution and the high-concentration antifreeze solution perform primary heat exchange in the second heat exchanger 11, recovering the sensible heat of the high-concentration antifreeze solution and preliminarily heating the low-concentration antifreeze so...

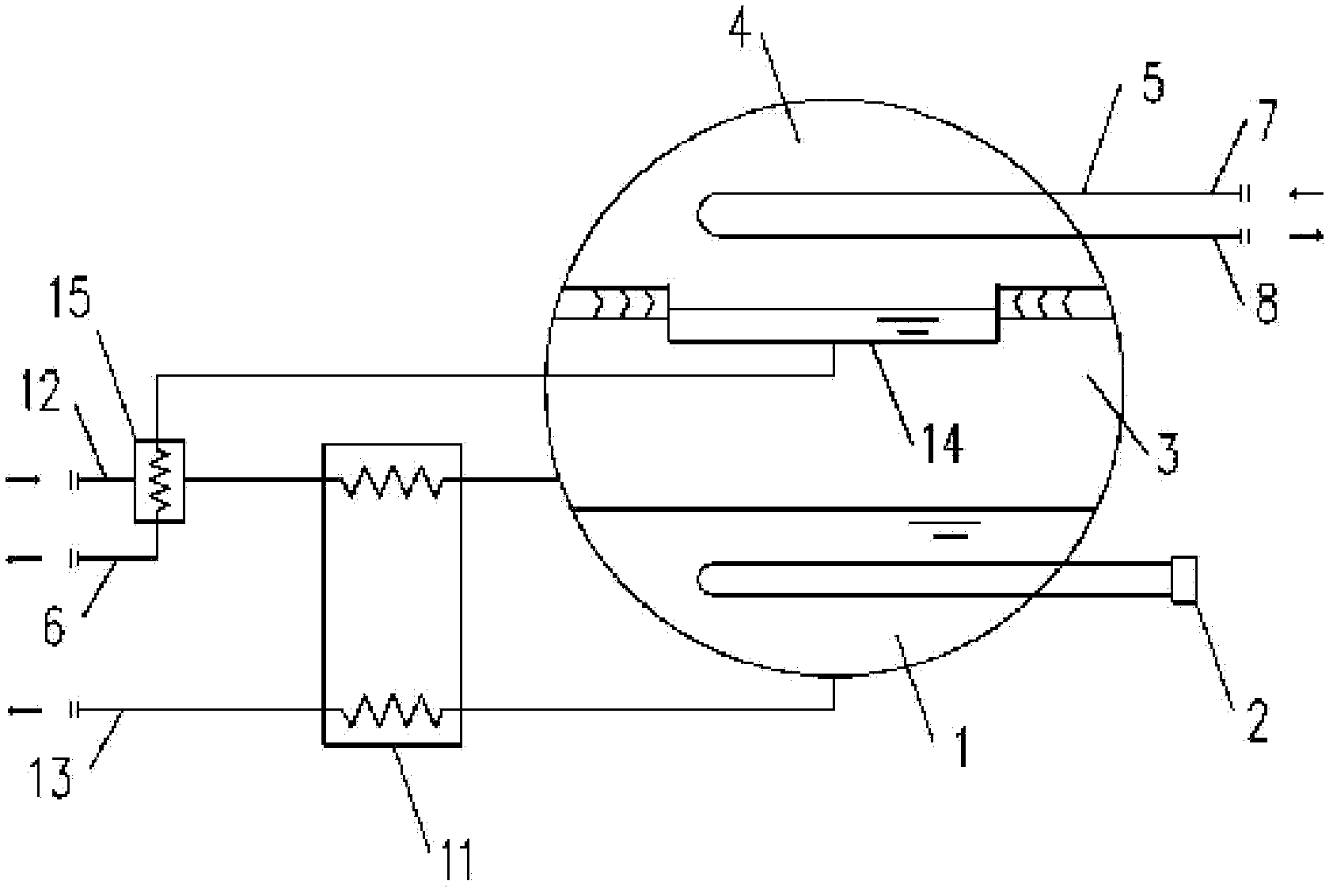

Embodiment 3

[0048] This embodiment is an improvement scheme of embodiment 2, in order to make the regenerative heat recovery efficiency in the regeneration container more significant, such as image 3 As shown, compared with Example 2, the difference is that a water pan 14 is provided below the first heat exchanger, and a third heat exchanger is provided at the low-concentration solution inlet 12 of the second heat exchanger 11. 15. The third heat exchanger 15 is connected to the water pan 14 through the condensed water channel. The condensed water channel passes through the third heat exchanger 15 and ends with the condensed water outlet 6. The low-concentration antifreeze solution channel 9 passes through the second heat exchanger in turn. 11 and the third heat exchanger 15, and the end of the low-concentration antifreeze solution channel 9 is the low-concentration solution inlet 12. The condensed water in the water vapor condensation heat recovery device 4 is received by the water pan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com