Metal selenide counter-electrode for dye-sensitized solar cell and preparation method of metal selenide counter-electrode

A technology for solar cells and metal selenide, applied in the field of solar cells, can solve the problems of harsh preparation conditions, high production costs, cumbersome experimental equipment or high temperature sintering, etc., and achieves the effect of simple process and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

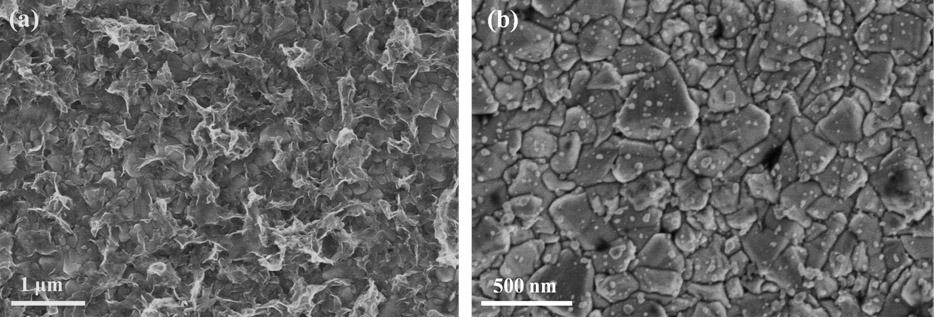

[0015] Example 1, 0.1 mmol cobalt chloride hexahydrate (CoCl 2 ·6H 2 (0) and 0.15 mmol selenium powder (purity 99.999%) were added in a 50 mL hydrothermal kettle, then 7.5 mL of hydrazine hydrate solution (content 85wt%) was added, and finally 30 mL of deionized water was added to make the volume of the mixed solution reach about 3 / 4 capacity. After fully stirring evenly, put a piece of thoroughly cleaned FTO conductive glass into the hydrothermal kettle, seal the hydrothermal kettle tightly, and conduct a hydrothermal reaction at 120°C for 12 h. After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the conductive glass was taken out, rinsed and dried.

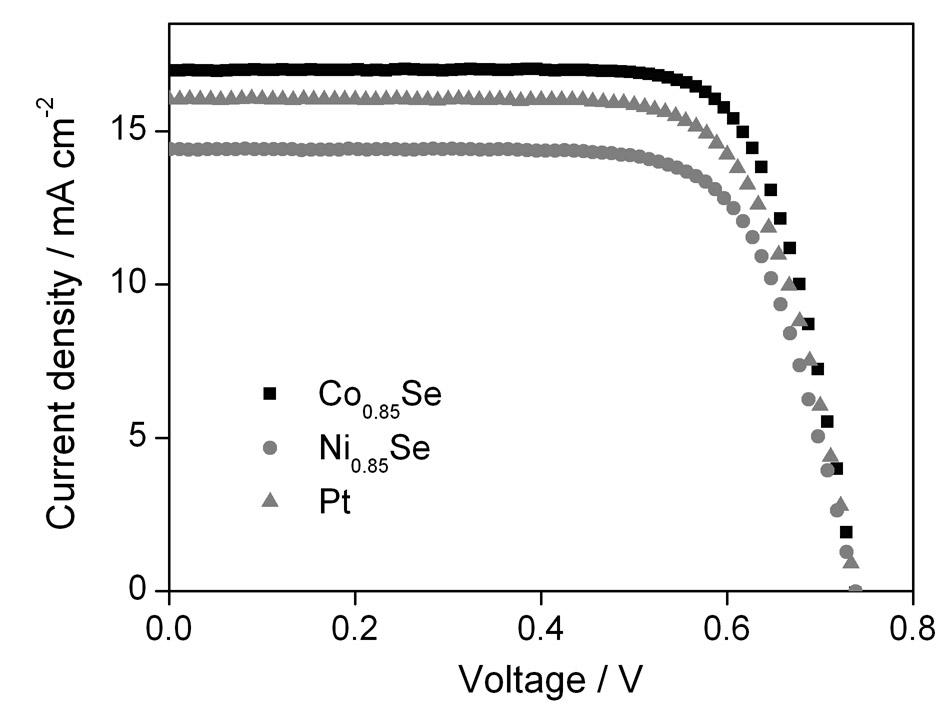

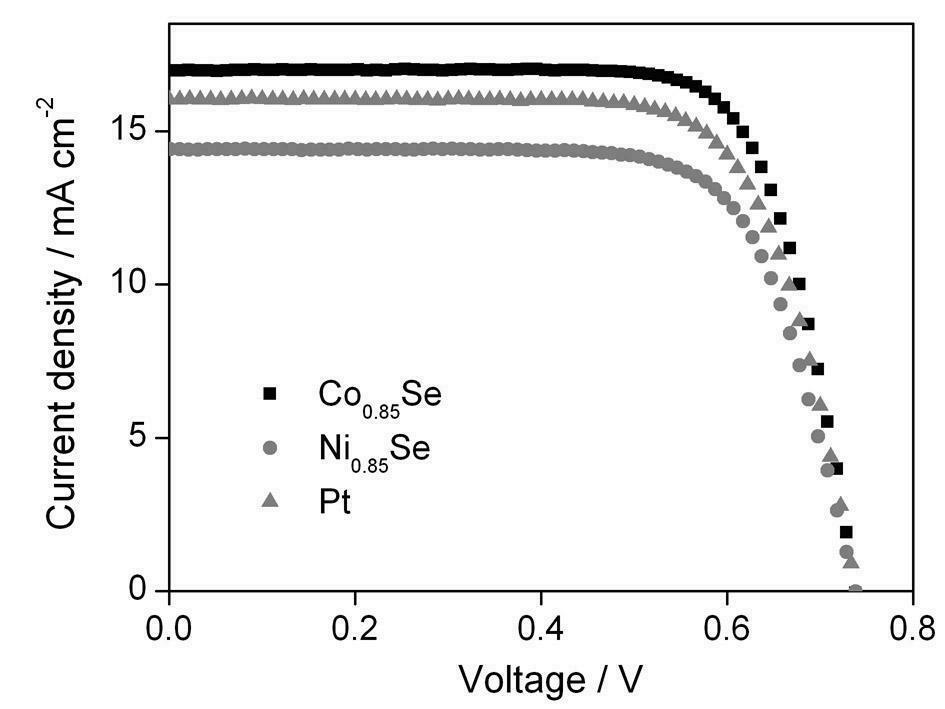

[0016] This counter electrode was assembled into DSSCs according to the standard method, with a cell area of 0.2304 cm 2 . The current-voltage (I-V) curve of the dye-sensitized solar cell was measured under AM1.5 simulated sunlight ( figure 2 shown in curve 1), to obtain the open cir...

Embodiment 2

[0017] Example 2, 0.2 mmol nickel chloride hexahydrate (NiCl 2 ·6H 2 (0) and 0.24 mmol selenium powder (purity 99.999%) were added in a 50 mL hydrothermal kettle, then 15 mL of hydrazine hydrate solution (content 85wt%) was added, and finally 22.5 mL of deionized water was added to make the volume of the mixed solution reach about 3 / 4 capacity. After fully stirring evenly, put a piece of thoroughly cleaned FTO conductive glass into the hydrothermal kettle, seal the hydrothermal kettle tightly, and conduct a hydrothermal reaction at 140°C for 10 h. After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the conductive glass was taken out, rinsed and dried.

[0018] This counter electrode was assembled into DSSCs according to the standard method, with a cell area of 0.2304 cm 2 . The I-V curve of the dye-sensitized solar cell was measured under AM1.5 simulated sunlight ( figure 2 shown in curve 2), we get V oc is 738 mV, J sc at 15.6...

Embodiment 3

[0019] Example 3, 0.2 mmol CoCl 2 ·6H 2 O and 0.4 mmol selenium powder (purity 99.999%) were added in a 50 mL hydrothermal kettle, then 20 mL of hydrazine hydrate solution (content 85wt%) was added, and finally 17.5 mL of deionized water was added to make the volume of the mixed solution reach about 3 / 4 capacity. After fully stirring evenly, put a piece of thoroughly cleaned FTO conductive glass into the hydrothermal kettle, seal the hydrothermal kettle tightly, and conduct a hydrothermal reaction at 100°C for 24 h. After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the conductive glass was taken out, rinsed and dried.

[0020] This counter electrode was assembled into DSSCs according to the standard method, with a cell area of 0.2304 cm 2 . The I-V curve of the dye-sensitized solar cell was measured under AM1.5 simulated sunlight, and obtained V oc is 722 mV, J sc at 14.74 mA / cm 2 , FF is 0.74, n is 7.88%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com