Manufacturing method of hollow nanotube structure

A manufacturing method and nanotube technology, applied in nanotechnology, microstructure technology, microstructure devices, etc., can solve the problems of complex and time-consuming process technology, inability to directly form nanotube structures, and affecting the optoelectronic properties of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

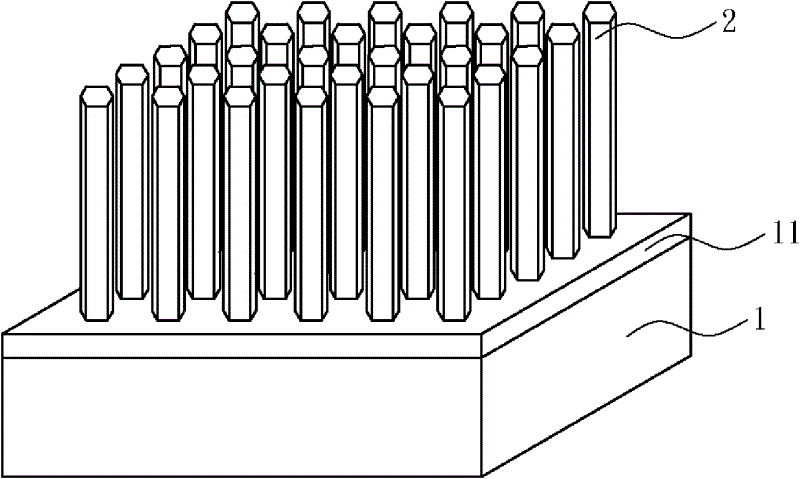

[0031] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be exemplified below in detail with accompanying drawings.

[0032] The invention relates to a manufacturing method of a hollow nanotube structure, which mainly utilizes a nanowire and an outer coating layer to produce a hollow nanotube (nanotube) structure with various unique physical and chemical properties, so that the hollow nanotube (nanotube) structure can be passed through the hollow nanotube Structural design of micro-electromechanical elements and sensing elements with various functions, for example, hollow nanotube structures can be used as light waveguide materials to supply various optoelectronic elements, such as photo detectors, solar cells ( Solar cell), Liquid Crystal Display (LCD) and Light Emitting Diode (LED), etc., so it has great business opportunities and application potential in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com