End-point fixing preparation method for multi-aldehyde alginic acid coating

A polyaldehyde-based sodium alginate, sodium alginate technology, applied in the direction of coating, special packaging items, packaging item types, etc., can solve the problems of poor anticoagulant activity, potential toxicity, poor biocompatibility, etc., and achieve low cost. , Natural low toxicity, mild reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

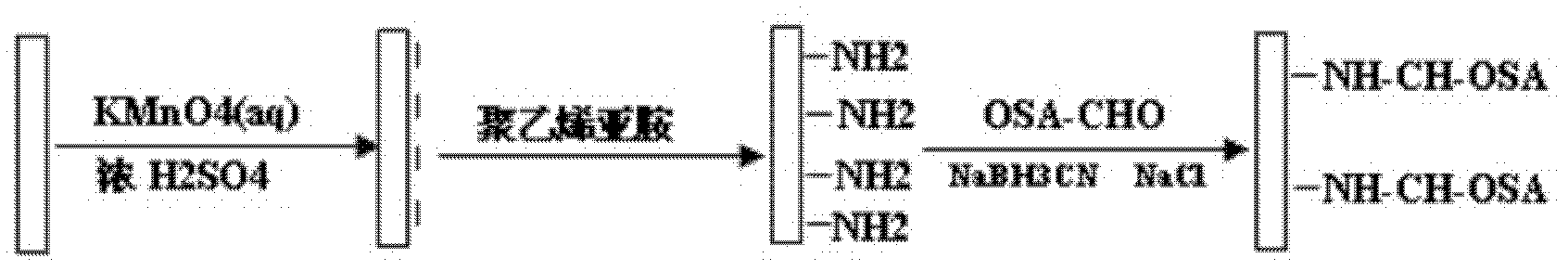

[0023] In the first step, 0.344 g of potassium permanganate was dissolved in 162 ml of deionized water, and 10 ml of 95 wt % concentrated sulfuric acid was slowly added to mix the concentrated sulfuric acid and potassium permanganate evenly.

[0024] In the second step, the polymer material PVC is added to the solution obtained in the first step, and the reaction is fully stirred for 10 minutes.

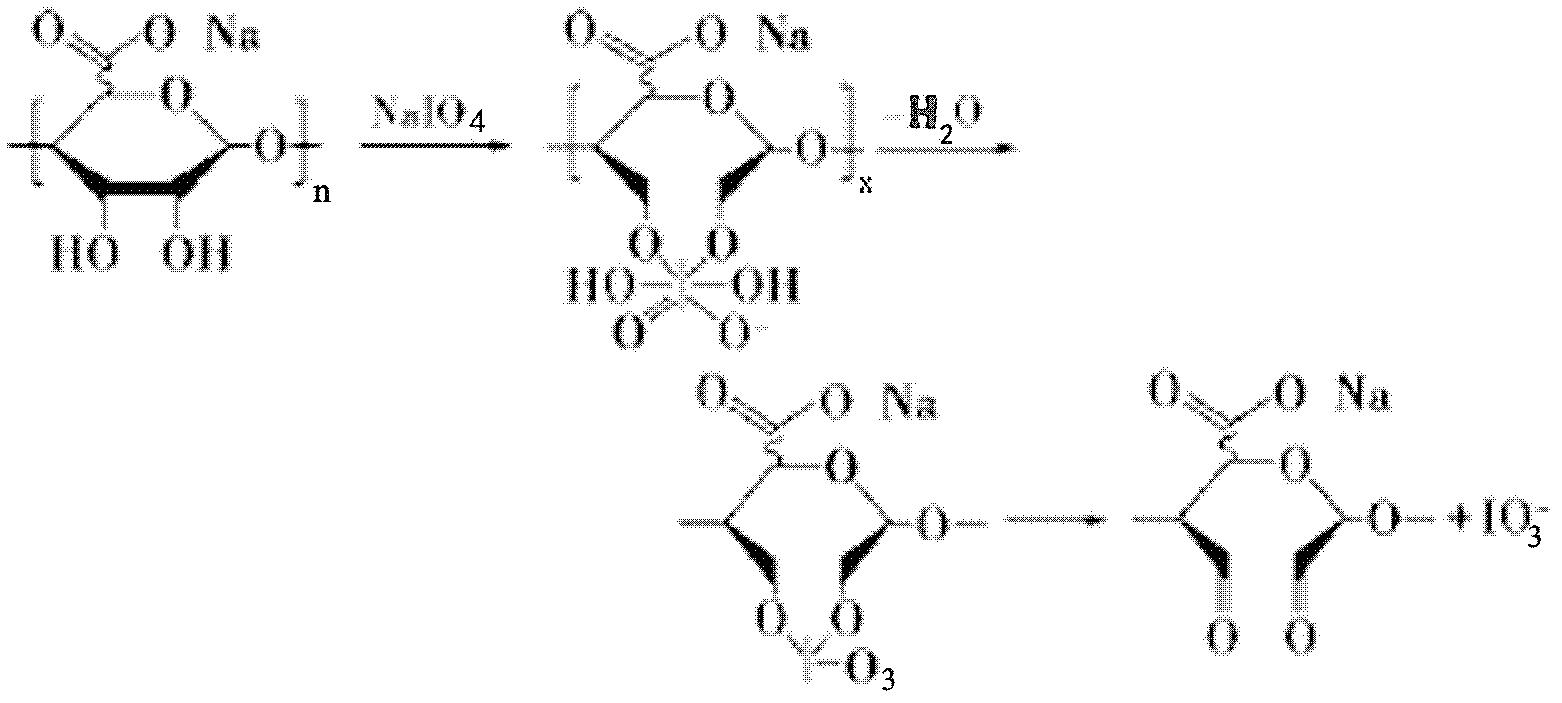

[0025] The third step is to oxidize the alginic acid according to the molar ratio of sodium periodate to sodium alginate unit of 1:10, so that the end of the alginic acid segment is exposed to aldehyde groups, ethylene glycol terminates the reaction, 96wt% ethanol aqueous solution is precipitated, and suction is filtered after the precipitation , dialyzed, and freeze-dried at -80°C to obtain polyaldehyde sodium alginate. The oxidation reaction was stirred and reacted for 24 hours in the dark.

[0026] In the fourth step, the polymer material pretreated in the second step is immersed...

Embodiment 2

[0030] In the first step, 0.328 g of potassium permanganate was dissolved in 144 ml of deionized water, and 20 ml of 95% concentrated sulfuric acid was slowly added to mix the concentrated sulfuric acid and potassium permanganate evenly.

[0031] In the second step, the polymer material is added to the solution obtained in the first step, and the mixture is stirred and fully reacted for 1 min.

[0032] The third step is to oxidize the alginic acid according to the molar ratio of sodium periodate and sodium alginate unit 3:10, so that the end of the alginic acid fragment is exposed to the aldehyde group, ethylene glycol terminates the reaction, 96% ethanol precipitation, suction filtration after precipitation, Dialyze and freeze-dry at -80°C to obtain polyaldehyde sodium alginate. The oxidation reaction was stirred and reacted for 40 hours in the dark.

[0033] In the fourth step, the polymer material pretreated in the second step is immersed in a 0.5% polyethyleneimine aqueou...

Embodiment 3

[0036] In the first step, 0.328 g of potassium permanganate was dissolved in 144 ml of deionized water, and 20 ml of 95% concentrated sulfuric acid was slowly added to mix the concentrated sulfuric acid and potassium permanganate evenly.

[0037] In the second step, the polymer material is added to the solution obtained in the first step, and stirred and fully reacted for 8 minutes.

[0038] The third step is to oxidize the alginic acid according to the molar ratio of sodium periodate and sodium alginate unit 1:10, so that the end of the alginic acid fragment is exposed to aldehyde groups, ethylene glycol terminates the reaction, 96% ethanol precipitates, and after the precipitation, suction filtration, Dialyze and freeze-dry at -80°C to obtain polyaldehyde sodium alginate. The oxidation reaction was stirred and reacted for 30 hours under the condition of avoiding light.

[0039] In the fourth step, the polymer material pretreated in the second step is immersed in a 0.05% pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com