Method for preparing titanium or titanium alloy super-hydrophobic surface

A super-hydrophobic surface and titanium alloy technology, which is applied in the field of metal surface treatment, can solve the problems of no literature reports on the super-hydrophobic surface of titanium or titanium alloy, and achieve the effects of easy large-area preparation, high processing efficiency, and good super-hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

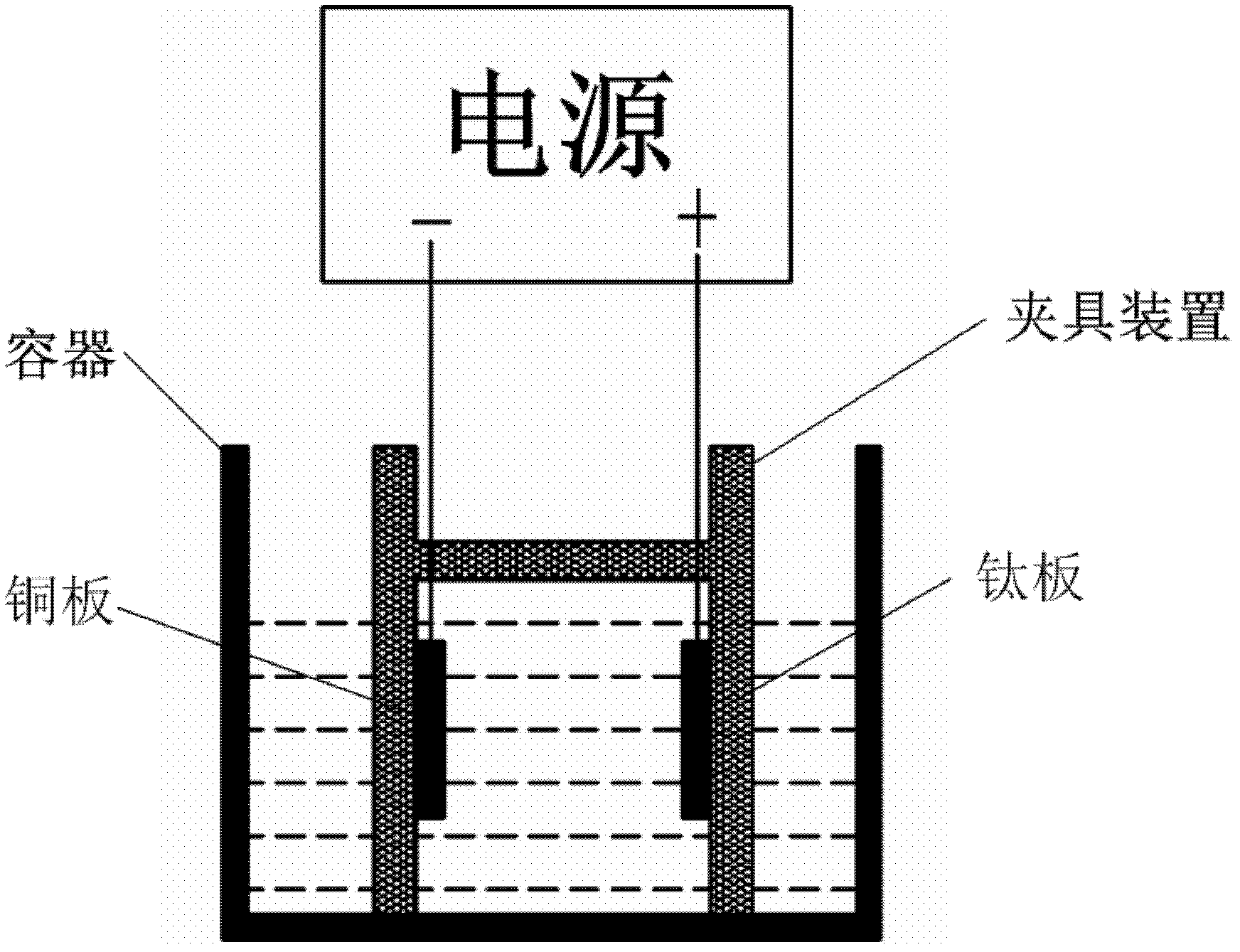

[0021] (1) Cut the titanium plate and cathode copper plate into 20mm×30mm, the actual processing area is 20mm×20mm, and the rest is used for clamping and conducting. Before processing, the titanium plate and the cathode copper plate are ultrasonically cleaned with absolute ethanol and deionized water in sequence, and dried.

[0022] (2) Fix the titanium plate and cathode copper plate symmetrically in parallel, the distance between the two plates is 10mm, the two plates are connected to the DC power supply through wires, the titanium plate is connected to the positive pole of the power supply, and the cathode copper plate is connected to the negative pole of the power supply; put the two plates into a container containing 0.2mol / L NaCl aqueous solution; connect the DC power supply, start processing, and the current density is 1A / cm 2 . During processing, the solution temperature is room temperature (about 25° C.), and the processing time is 3 minutes.

[0023] (3) After the ...

Embodiment 2

[0025] (1) Cut the titanium plate and cathode copper plate into 20mm×30mm, the actual processing area is 20mm×20mm, and the rest is used for clamping and conducting. Before processing, the titanium plate and the cathode copper plate are ultrasonically cleaned with absolute ethanol and deionized water in sequence, and dried.

[0026] (2) Fix the titanium plate and cathode copper plate symmetrically in parallel, the distance between the two plates is 10mm, the two plates are connected to the DC power supply through wires, the titanium plate is connected to the positive pole of the power supply, and the cathode copper plate is connected to the negative pole of the power supply; put the two plates into a container containing 0.2mol / L NaBr aqueous solution; connect the DC power supply, start processing, the current density is 0.5A / cm 2 . During processing, the solution temperature is room temperature (about 25° C.), and the processing time is 15 minutes.

[0027] (3) After the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com