Formula of acid and alkali-resistant and anti-pollution ultrafiltration membrane and preparation method thereof

An anti-pollution, ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reduced separation efficiency, poor hydrophilicity, easy pollution, etc., and achieve improved mechanical strength, strong resistance Pollution ability, effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

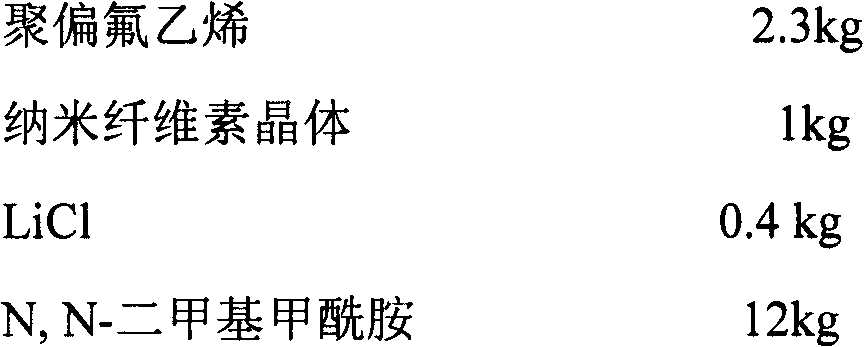

[0027] 1. Prepare materials according to the following weight ratio:

[0028]

[0029] 2. Preparation of ultrafiltration membrane:

[0030] 1) Raw material drying:

[0031] The above several raw materials (except the solvent) are dried in a hot air oven at 105°C for subsequent use.

[0032] 2) Preparation of polyvinylidene fluoride-nanocellulose crystal-LiCl mixed solution

[0033] Add the dried polyvinylidene fluoride into the solvent, stir to completely dissolve the polyvinylidene fluoride, then add nanocellulose crystals, continue to stir to dissolve, continue to add LiCl, and stir well to obtain polyvinylidene fluoride-nano Cellulose crystal-LiCl mixture.

[0034] 3) Casting liquid degassing

[0035] Put polyvinylidene fluoride-nanocellulose crystals-LiCl mixture in a double-layer vacuum barrel, use a vacuum pump to decompress and degas the vacuum barrel, and pass water or oil with a controlled temperature in the interlayer of the double-layer vacuum barrel , adjus...

Embodiment 2

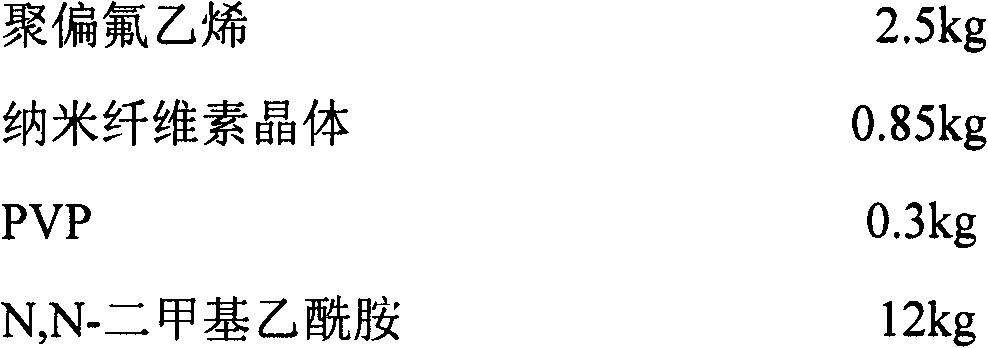

[0044] 1) Prepare materials according to the following weight ratio:

[0045]

[0046] The formula and process steps of preparing the film in this example are the same as Example 1 except that the formula of the film casting solution is changed from the formula described in Example 1.

[0047] The performance index of the polyvinylidene fluoride composite ultrafiltration membrane prepared in this example, the test results are shown in Table 1.

Embodiment 3

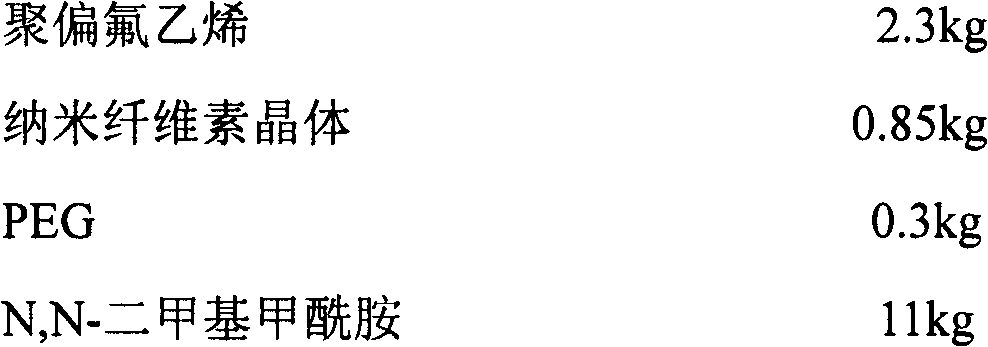

[0049] 1) Prepare materials according to the following weight ratio:

[0050]

[0051] The formula and process steps of preparing the film in this example are the same as Example 1 except that the formula of the film casting solution is changed from the formula described in Example 1.

[0052] The performance index of the polyvinylidene fluoride composite ultrafiltration membrane prepared in this example, the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com