Synthetic method of polylactic acid-polyethylene glycol

A polyethylene glycol and synthesis method technology, applied in the field of material chemistry, can solve the problems of application limitation, high cost, low molecular weight of polylactic acid-polyethylene glycol, etc., and achieve complete degradation cycle, short degradation cycle and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

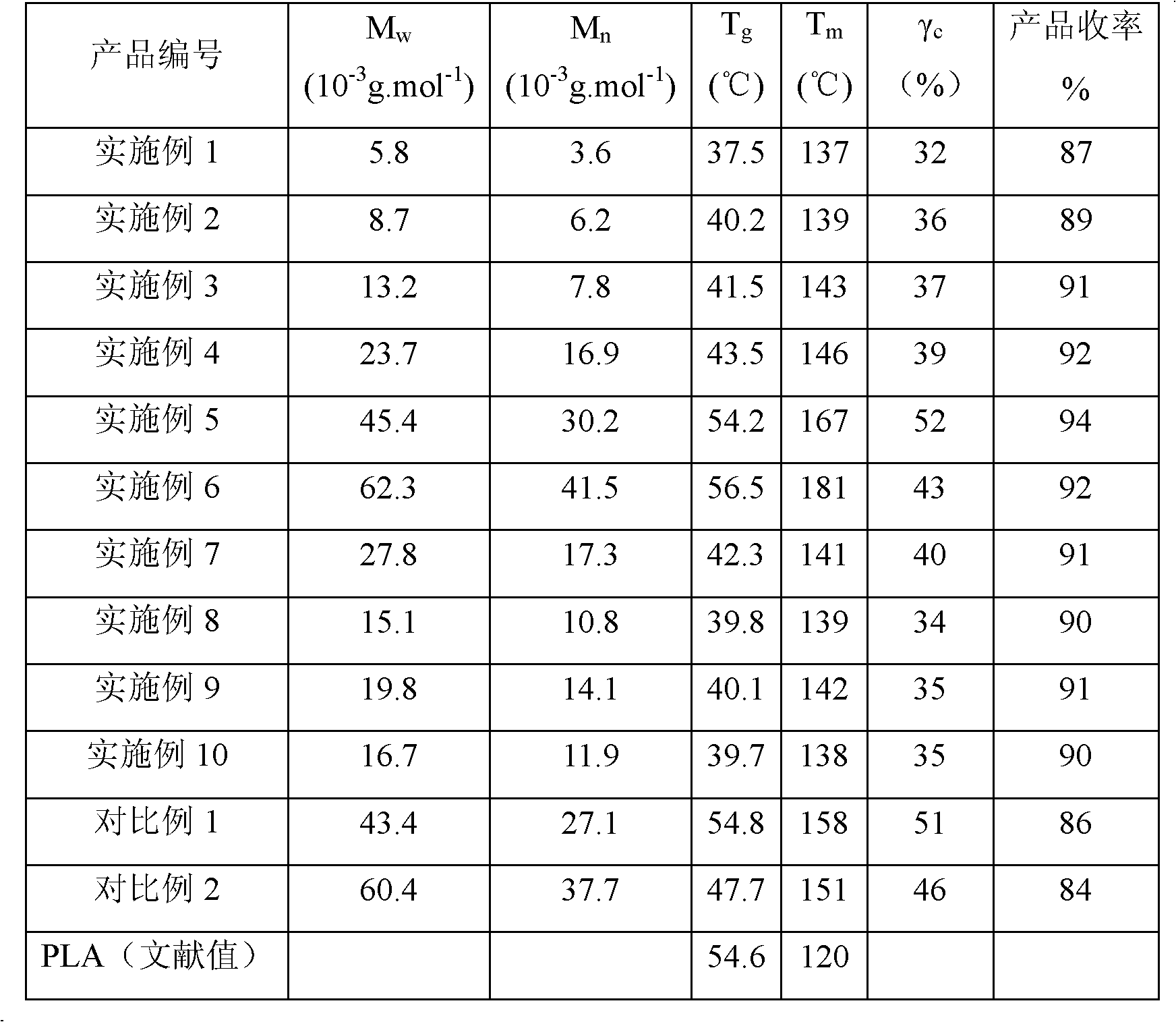

Embodiment 1

[0026] Firstly, the L-lactic acid to be reacted was dried with 5A molecular sieve for 2-3 hours, and then placed for use. In a 250 ml reaction flask, add 200 grams of preliminarily dried L-lactic acid, 22 grams of PLEG with a molecular weight of 400, and 0.1 grams of 1,3-dimethylimidazole p-toluenesulfonate, then heat to reflux and control with a vacuum pump The pressure in the reaction bottle is 800Pa, 170°C, stir and react for 6 hours, then slowly cool down to room temperature to obtain a brownish-yellow solid, add 50 ml of chloroform solvent, stir and dissolve the reactant, and then add it dropwise while stirring with methanol until it becomes cloudy , and a precipitate slowly precipitated out, and stood still for 1 hour. After the precipitation was completed, the crude product was obtained by vacuum filtration. Then recrystallize with chloroform-acetone complex solvent to obtain refined polylactic acid-polyethylene glycol product. The molecular weight of the copolymer was...

Embodiment 2

[0028]Firstly, the L-lactic acid to be reacted was dried with 5A molecular sieve for 2-3 hours, and then placed for use. In a 250 ml reaction flask, add 200 grams of preliminarily dried L-lactic acid, 25 grams of PLEG with a molecular weight of 600, 0.1 gram of 1-ethyl-3-methylimidazole p-toluenesulfonate, and then heat to reflux, And use a vacuum pump to control the pressure in the reaction bottle to be 800 Pa, 170 ° C, stir and react for 6 hours, then slowly cool down to room temperature, add 50 ml of chloroform solvent, stir and dissolve the reactant, then add dropwise while stirring with methanol until turbidity occurs, And a precipitate slowly precipitated out, and stood still for 1 hour. After the precipitation was completed, the crude product was obtained by vacuum filtration. Then recrystallize with chloroform-acetone complex solvent to obtain refined polylactic acid-polyethylene glycol product. The molecular weight of the copolymer was measured by GPC, the thermal an...

Embodiment 3

[0030] Firstly, the L-lactic acid to be reacted was dried with 5A molecular sieve for 2-3 hours, and then placed for use. In a 500 ml reaction bottle, add 300 grams of preliminarily dried L-lactic acid, 35 grams of PLEG with a molecular weight of 1000, 0.1 gram of 1-ethyl-2,3-dimethylimidazole methanesulfonate, and then heat to Reflux, and use a vacuum pump to control the pressure in the reaction bottle to 600 Pa, 175 ° C, stir for 6 hours, then slowly cool down to room temperature, add 80 ml of chloroform solvent, stir and dissolve the reactant, and then add it dropwise while stirring with methanol until it appears It was turbid, and a precipitate slowly precipitated out. After standing still for 1 hour, the precipitation was completed, and the crude product was obtained by vacuum filtration. Then recrystallize with chloroform-acetone complex solvent to obtain refined polylactic acid-polyethylene glycol product. The molecular weight of the copolymer was measured by GPC, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com