High-energy-storage density dielectric material and preparation method thereof

A technology of high energy storage density and dielectric materials, applied in the field of high energy storage density dielectric materials and their preparation, can solve the problems of reducing composite materials, brittleness, poor mechanical properties, etc., and achieve the effect of avoiding brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

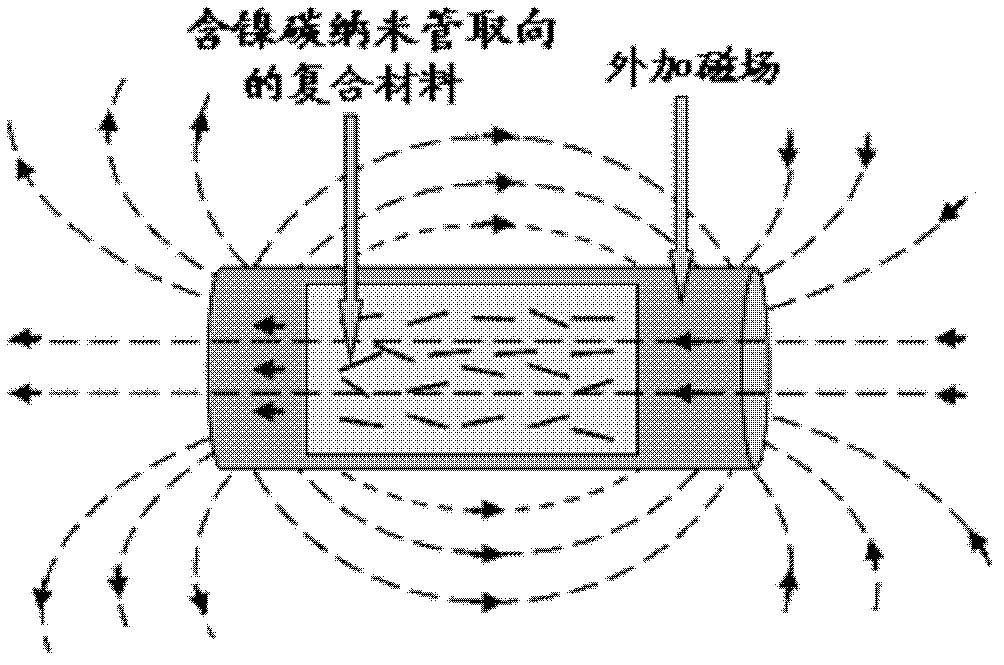

[0028] (1) Disperse 0.02 g of nickel-containing carbon nanotubes in 100 ml of DMF solvent, stir on a mechanical stirrer for 1 h, and then put them into an ultrasonic apparatus for ultrasonic treatment for 1 h.

[0029] (2) Dissolve 1.98g of polyvinylidene fluoride in 50ml of DMF solvent, then pour the stirred and ultrasonically treated nickel-containing carbon nanotube solution into the polyvinylidene fluoride solution, and continue to stir on a magnetic stirrer for 1h.

[0030] (3) Pour the obtained complex solution into a petri dish, and dry the solvent in an oven at 100° C. until the inclined petri dish can just flow;

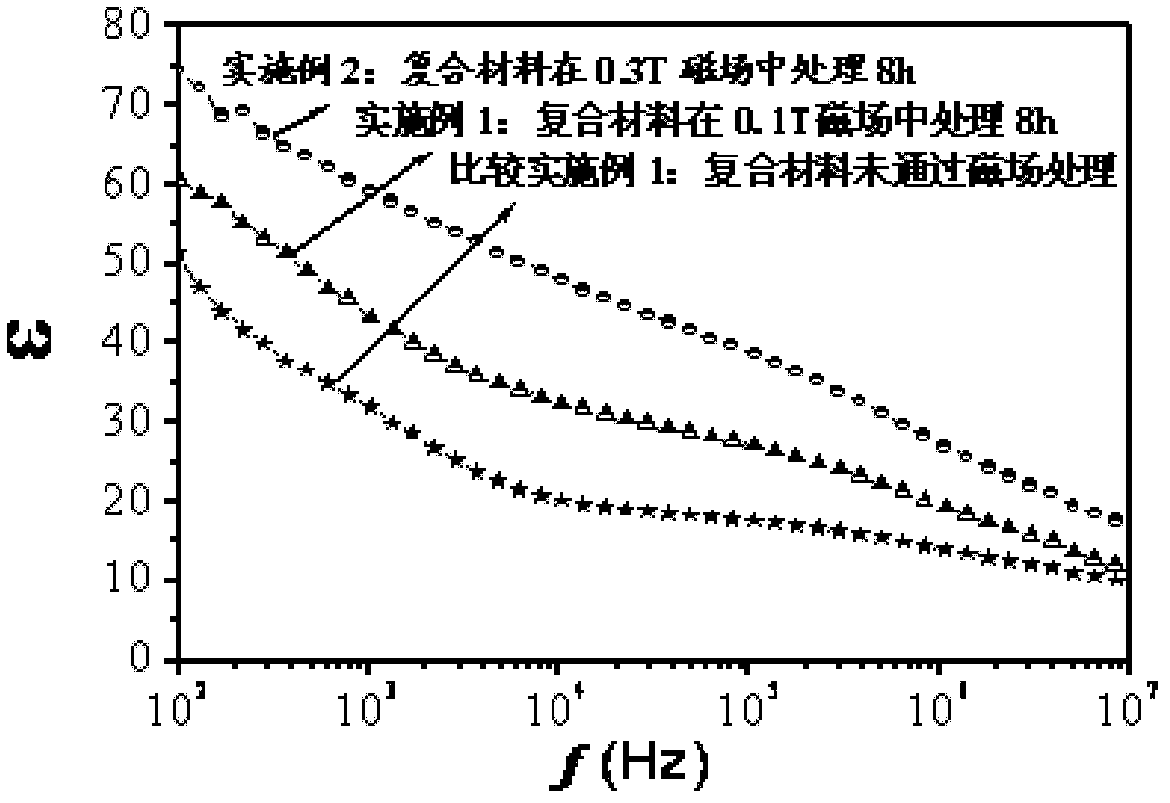

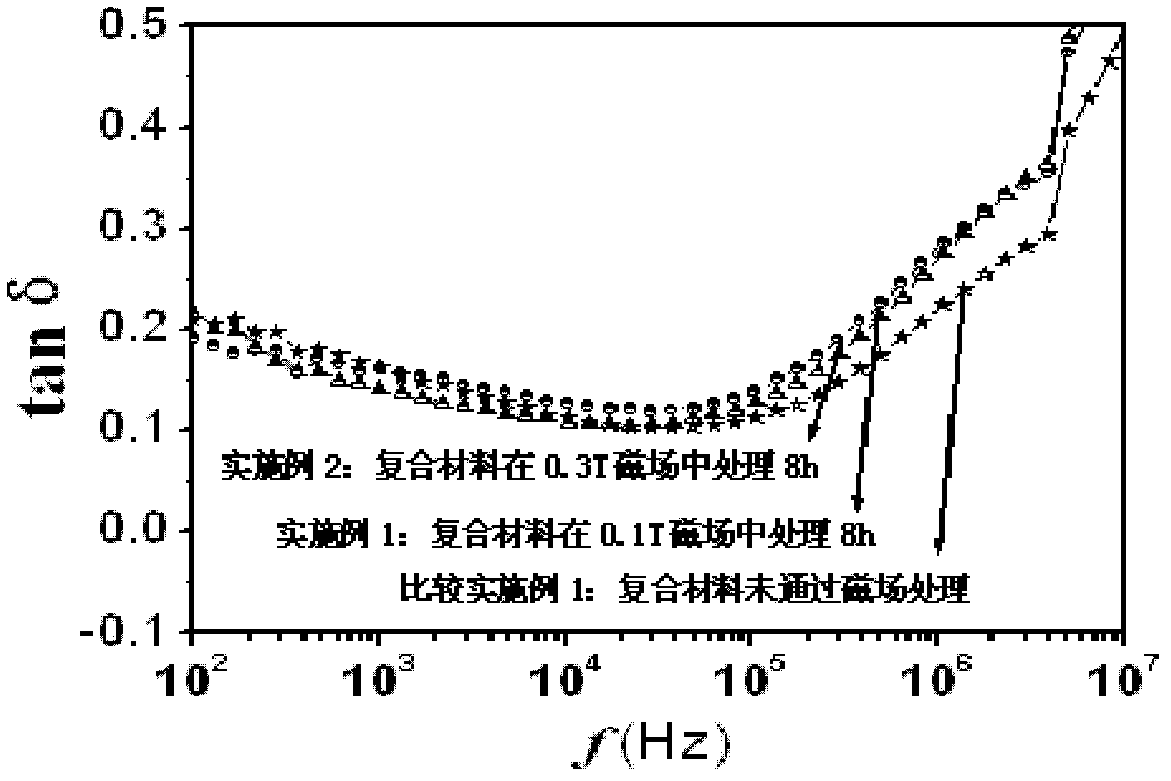

[0031] (4) Place the composite in a 0.1T magnetic field for 8 hours and then dry the solvent in an oven at 100°C to obtain a composite film;

[0032] (5) Cut the composite film and put it into a mold, put it on a hot press at 180° C. and 18 MPa constant pressure for 10 minutes, and press it into a disc sample with a thickness of 1 mm and a diameter of 12 mm....

Embodiment 2

[0035] (1) Disperse 0.02 g of nickel-containing carbon nanotubes in 100 ml of DMF solvent, stir on a mechanical stirrer for 1 h, and then put them into an ultrasonic apparatus for ultrasonic treatment for 1 h.

[0036] (2) Dissolve 1.98g of polyvinylidene fluoride in 50ml of DMF solvent, then pour the stirred and ultrasonically treated nickel-containing carbon nanotube solution into the polyvinylidene fluoride solution, and continue to stir on a magnetic stirrer for 1h.

[0037] (3) Pour the obtained complex solution into a petri dish, and dry the solvent in an oven at 100° C. until the inclined petri dish can just flow;

[0038] (4) Place the composite in a 0.3T magnetic field for 8 hours and then dry the solvent in an oven at 100°C to obtain a composite film;

[0039](5) Cut the composite film and put it into a mold, put it on a hot press at 180° C. and 18 MPa constant pressure for 10 minutes, and press it into a disc sample with a thickness of 1 mm and a diameter of 12 mm. ...

Embodiment 3

[0042] (1) Disperse 0.1 g of nickel-containing carbon nanotubes in 100 ml of DMF solvent, stir on a mechanical stirrer for 3 h, and then put them into an ultrasonic apparatus for ultrasonic treatment for 1 h.

[0043] (2) Dissolve 1.9 g of polyvinylidene fluoride in 50 ml of DMF solvent, then pour the stirred and ultrasonically treated nickel-containing carbon nanotube solution into the polyvinylidene fluoride solution, and continue stirring on a magnetic stirrer for 1 h.

[0044] (3) Pour the obtained complex solution into a petri dish, and dry the solvent in an oven at 80° C. until the inclined petri dish can just flow;

[0045] (4) Place the composite in a 0.1T magnetic field for 5 hours and then dry the solvent in an oven at 80°C to obtain a composite film;

[0046] (5) Cut the composite film and stack it into a mold, press on a hot press at 160° C. and 20 MPa constant pressure for 10 minutes, and press it into a disc sample with a thickness of 1 mm and a diameter of 12 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com