Control method of intermediate phase carbon microball D50 and device for producing intermediate phase carbon microball

A technology of mesophase carbon microspheres and pretreatment devices, which is applied in the direction of carbon preparation/purification, etc., can solve the problems of inconvenient catalyst addition, intense catalytic reaction, and long addition time, so as to reduce production costs, overcome uneven mixing, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

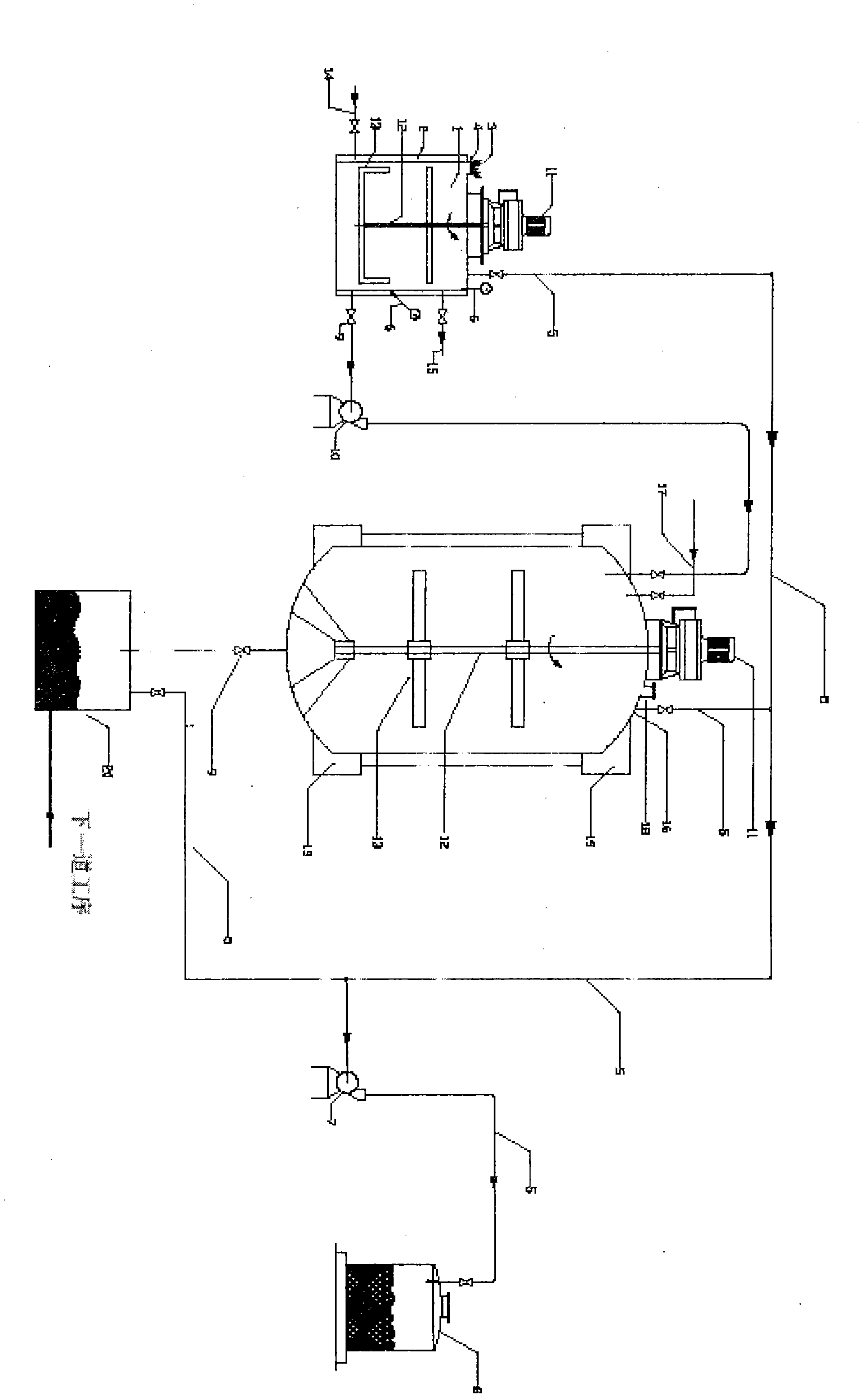

Method used

Image

Examples

Embodiment 1

[0055] Example 1 Preparation of mesocarbon microspheres

[0056] 12 batches of coal tar pitch from different sources or treatments were selected, and the primary quinoline insoluble matter was tested according to "GB 2293-1980 Coal Pitch Quinoline Insoluble Matter Determination Method".

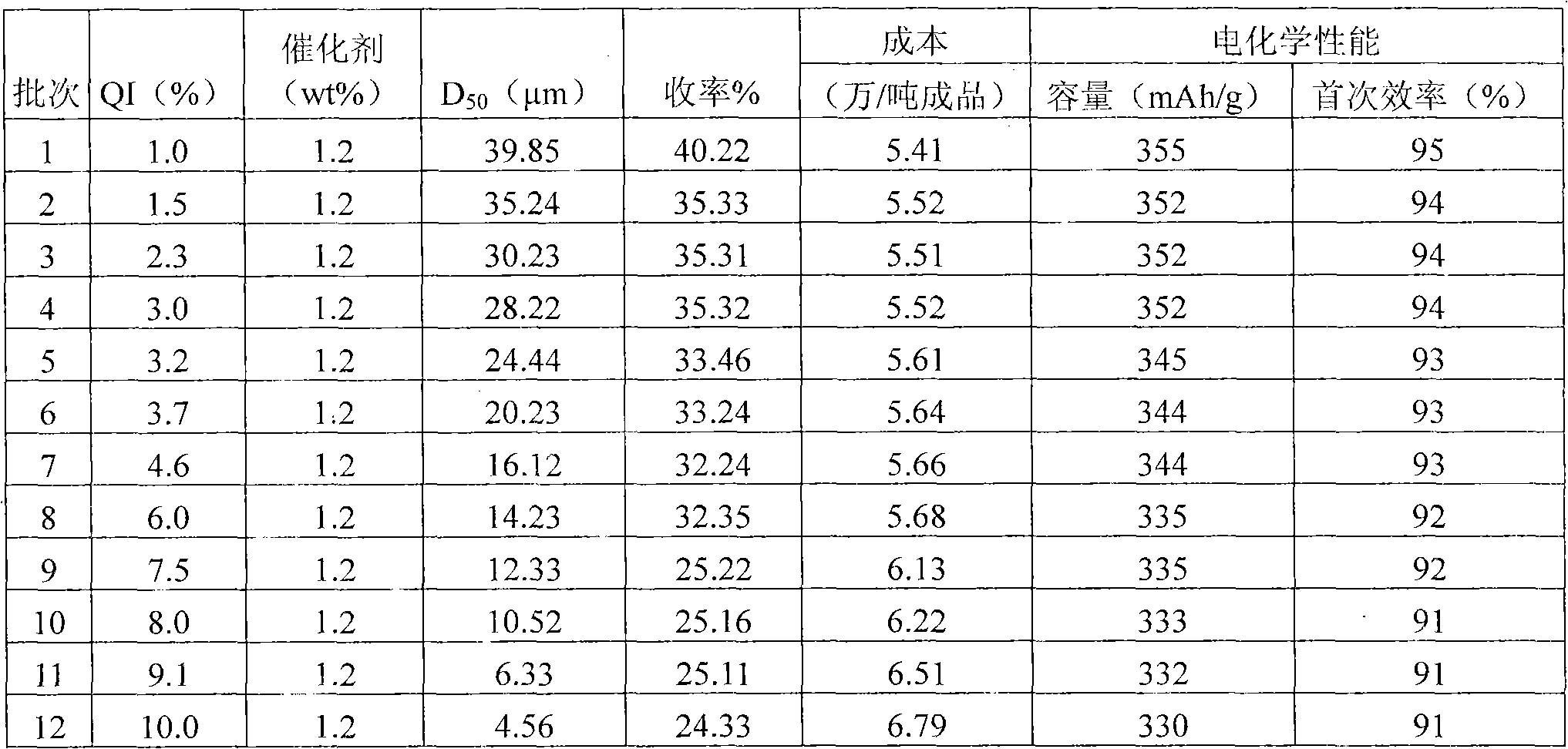

[0057] Take 400 grams of coal tar pitch from each batch and add them to the reactor, add 5.6 grams of iron oxide, and react for 4 hours at 420°C and 0.6Mpa to prepare the mesophase pellet precursor, and then reduce the mesophase. The precursor body of the ball is carbonized and graphitized to obtain the required D 50 Of mesophase carbon microspheres. Using the laser method and the British Malvern-Mastersizer 2000 laser particle size analyzer to determine its D 50 . The results are shown in Table 1.

[0058] Table 112 Preparation conditions and results of mesophase carbon microspheres from coal pitch

[0059]

[0060] It can be seen from Table 1 that the particle size of mesocarbon microspheres can...

Embodiment 2

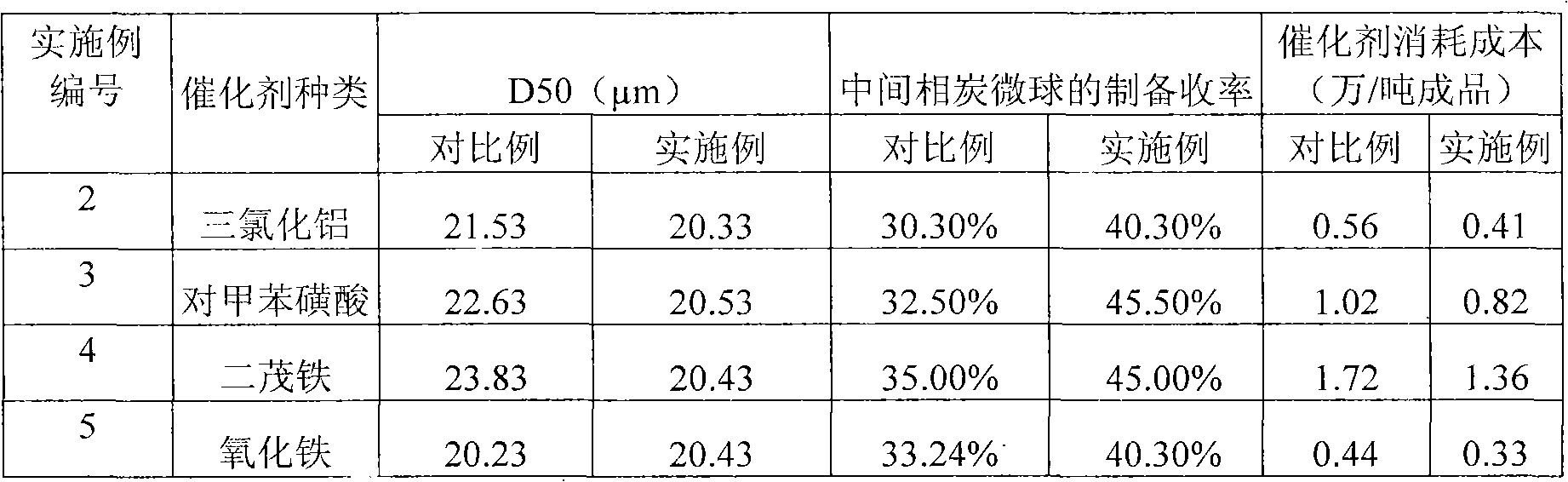

[0061] Example 2 Preparation of mesocarbon microspheres and comparative study on the pretreatment effect of catalyst aluminum trichloride

[0062] According to "GB 2293-1980 Coal Pitch Quinoline Insoluble Matter Determination Method", the content of primary quinoline insoluble matter in coal pitch was determined to be 3.7%.

[0063] Open the feeding butterfly valve of the catalyst pretreatment device, add aluminum trichloride from the catalyst feeding bin, add hot water from the water inlet, open the water outlet, and keep the heating temperature of the water bath at 50-100°C. After the catalyst is heated to melt and mix uniformly, pass the metering The system injects the treated aluminum trichloride into the reaction kettle, mixes it evenly with the pitch, and performs thermal polycondensation reaction to prepare mesophase carbon microspheres.

[0064] Similarly, 80-100 kg of the catalyst aluminum trichloride is directly injected into the reaction kettle, and mixed with the pitch f...

Embodiment 3

[0066] Example 3 Study on the preparation of mesocarbon microspheres and the pretreatment effect of the catalyst ferrocene

[0067] According to "GB 2293-1980 Coal Pitch Quinoline Insoluble Matter Determination Method", the content of primary quinoline insoluble matter in coal pitch was determined to be 3.7%.

[0068] Open the feeding butterfly valve of the catalyst pretreatment device, add 80-100kg of catalyst ferrocene from the catalyst feeding bin, add hot water from the water inlet, open the water outlet, keep the heating temperature of the water bath at 50-100°C, and wait until the catalyst is heated to melt and mix evenly , Through the metering system, the treated ferrocene is injected into the reaction kettle to mix it uniformly with the pitch and perform thermal polycondensation reaction to prepare mesocarbon microspheres.

[0069] Similarly, 80-100kg of the catalyst ferrocene is directly injected into the reaction kettle, and mixed with the pitch for thermal polycondensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com