Method for recovering phenol and acetophenone from phenol tar

A technology of acetophenone and phenol tar, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve problems such as high equipment maintenance costs, difficult residue handling, and difficult discharging, and achieves The content of heavy components is significantly reduced, the catalytic effect is good, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

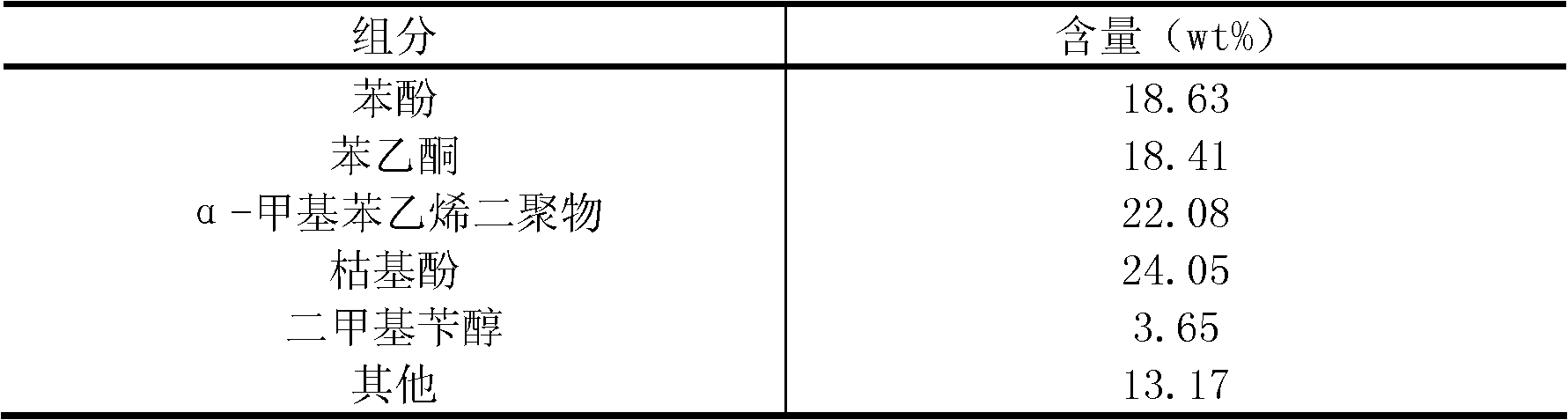

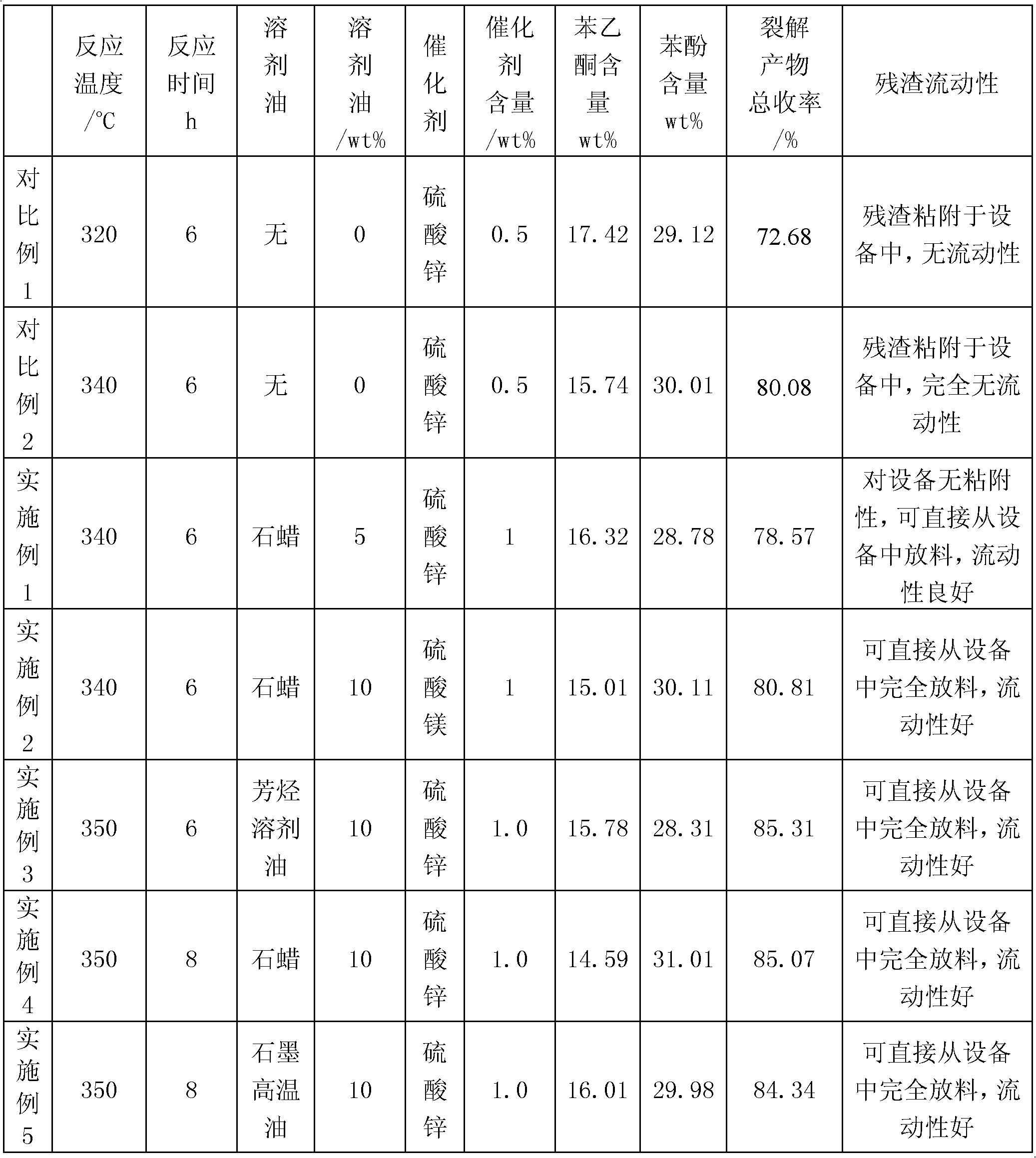

[0015] Add a certain amount of phenol tar to the reactor, the added catalyst content is 0.1-2% (based on the mass of phenol tar), and at the same time add about 5-15% of a high-temperature solvent oil (solvent oil with a boiling range above 240°C) (Based on the mass of phenol tar), stir and heat, first raise the temperature to 240-260 ° C for a certain period of time, distill the light components in it, and dissolve the catalyst evenly and thoroughly in the phenol tar, then raise the temperature The catalytic cracking reaction is carried out at a temperature of 320-360°C, and the reaction time is controlled at 1.5-10 hours. The mixture obtained by catalytic cracking was qualitatively and quantitatively analyzed by mass spectrometry, and the experimental results are shown in Table-2.

[0016] In Comparative Examples 1 and 2, the last residue is very viscous to the station of the equipment at 200°C, and apparently has no fluidity, but remains in the reaction equipment in the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com