Water and leakage plugging material of retarded crosslinking gel wrapping high valence metal ions

A high-valent metal ion, cross-linked gel technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of formation fluid mixing and flow away, and achieve slow hydration expansion and small filtration loss. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

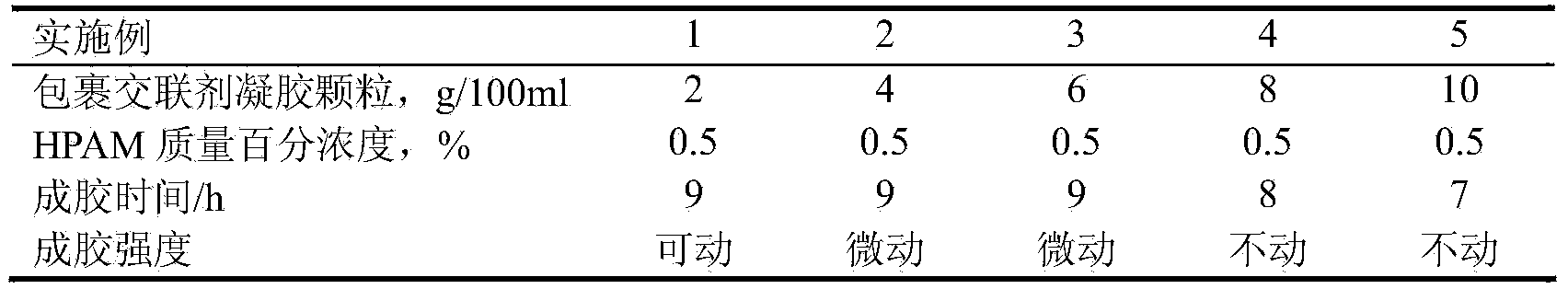

example 1~10

[0015] First, add 20 grams of acrylamide and 1 gram of styrene into a beaker filled with 73 grams of deionized water, then add 0.01 grams of N, N-methylenebisacrylamide and 6 grams of zirconium tetrachloride, and then add them respectively 0.01 gram of ammonium persulfate and 0.01 gram of sodium sulfite, after gelatinization at room temperature for 0.5h, stand still for 1h to obtain a gel block product, which is finally granulated, dried at 85°C, and sieved into solid phase gel particles; Add 120 grams of o-xylene and 3 grams of dispersant Span-80 into a three-necked flask with a stirrer, water receiver and reflux condenser, and the solution is used as the oil phase; add 20 g of 0.1 to 0.5 mm solid-phase gel particles Add 20 grams of polyvinyl alcohol aqueous solution with a mass fraction of 10% to obtain a uniformly dispersed suspension; control the stirrer speed to 350-400n / min, pour the suspension into the oil phase solution, and add anti-adhesive liquid paraffin 2 grams, a...

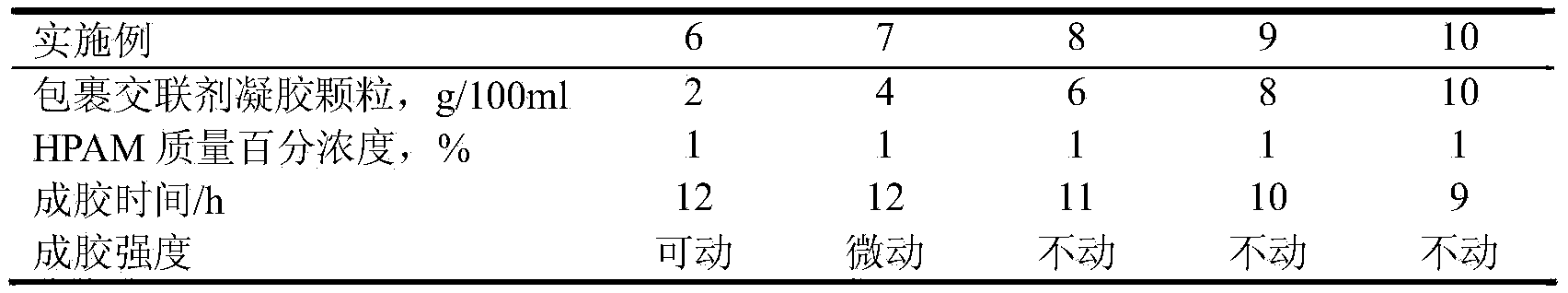

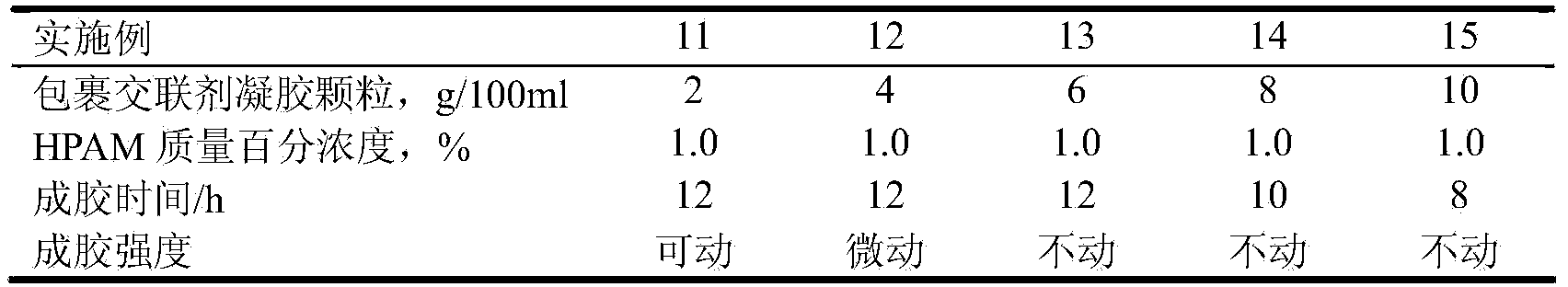

example 11~20

[0023] First add 25 grams of acrylamide and 1.5 grams of styrene into a beaker filled with 70.5 grams of deionized water, then add 0.015 grams of N, N-methylenebisacrylamide and 3 grams of aluminum trichloride after completely dissolving 0.02 grams of potassium persulfate and 0.02 grams of sodium bisulfite, after gelatinization at room temperature for 0.5 hours, stand still for 1 hour to obtain a gel block product, which is finally granulated, dried at 85°C, and sieved into a solid phase gel Particles; add 150 toluene and 3 grams of dispersant Span-80 in a three-necked flask with a stirrer, water receiver and reflux condenser, and the solution is used as the oil phase; add 20 g of 0.1 to 0.5 mm solid phase gel particles Add 20 grams of polyvinyl alcohol aqueous solution with a mass fraction of 10% to obtain a uniformly dispersed suspension; control the stirrer speed to 350-400n / min, pour the suspension into the oil phase solution, and add anti-adhesive liquid paraffin 2 grams,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com