Preparation and application of Pt-Cu alloy hollow nanoparticle enzyme-free glucose sensor electrode

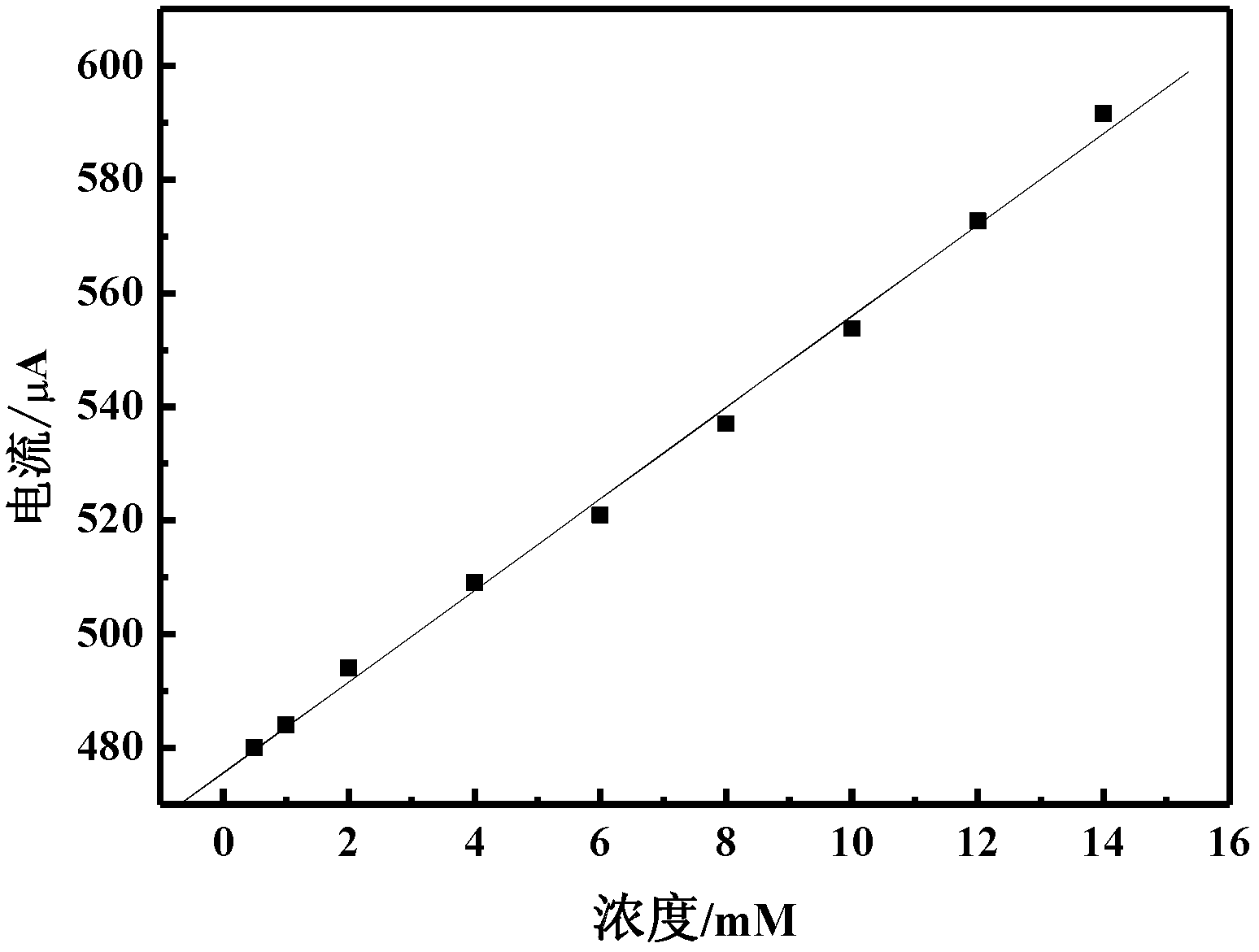

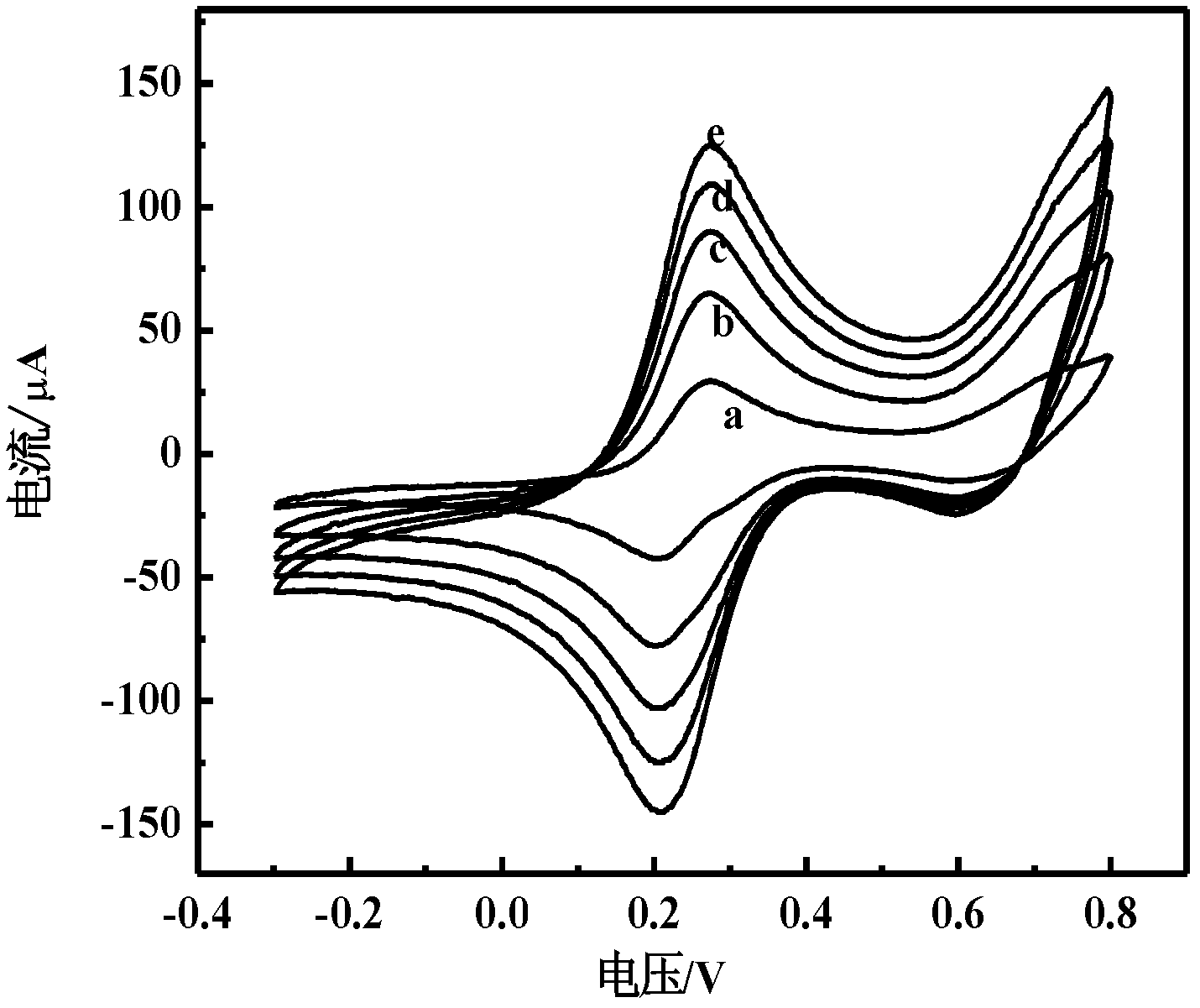

A glucose sensor and alloy nanoparticle technology, which is applied in the preparation and application of Pt-Cu alloy hollow nanoparticle enzyme-free glucose sensor electrodes, can solve the problems of loss of glucose electrocatalytic oxidation activity and poor selectivity, and achieve a wide detection linear range , Large current response, small toxin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

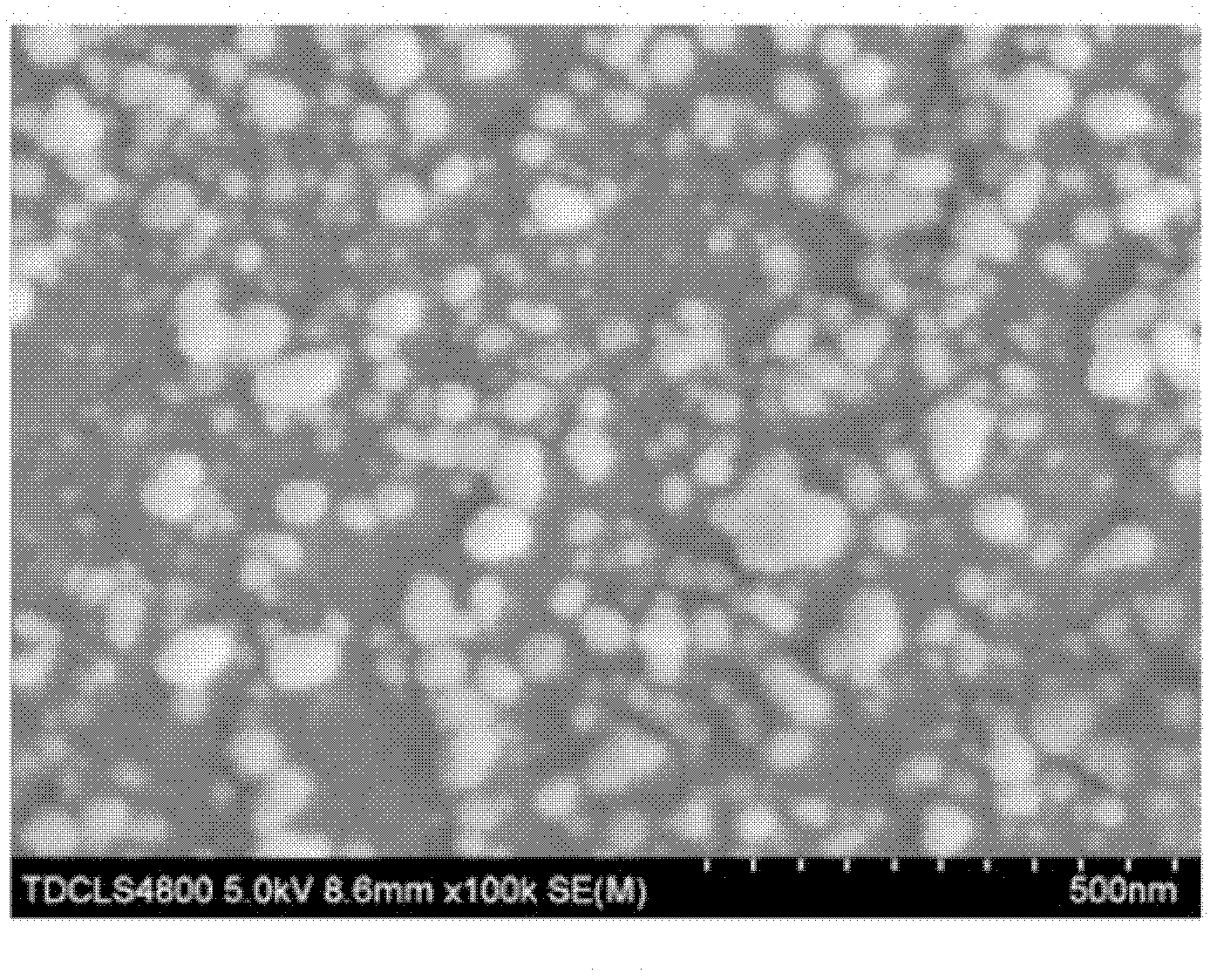

Embodiment 1

[0032]Grind and polish the Au electrode on the animal skin, rinse it repeatedly with twice distilled water, and ultrasonicate for 5 minutes in an ultrasonic cleaner with a power of 100-150 watts, then place it in PBS with a pH of 7.0 and activate it by cyclic voltammetry scanning for 10 cycles spare. First, 50 μl of 0.1mol / L CuCl 2 With 50 μl of 1mol / L sodium citrate (C 6 h 5 o 7 Na 3 2H 2 O) Dissolve in 20ml of double distilled water, stir for 5 minutes, then continue to stir, inject 1ml 0.025mol / L sodium borohydride (NaBH 4 ), and stirred for 15 minutes. Cu-Pt alloy nanoparticles were prepared by the method of current displacement, that is, 3.2ml of 0.1×10 -3 mol / L chloroplatinic acid. Then, after stirring and reacting for 20 minutes, the solution was reacted statically at room temperature (14±2°) for 24 hours. Centrifuge at a rotational speed of 12000r / min for 15 minutes, and repeatedly wash with double distilled water to completely remove remaining unreacted subst...

Embodiment 2

[0034] First, 50 μl of 0.1mol / L CuCl 2 With 60μl 0.1mol / L sodium citrate (C 6 h 5 o 7 Na 3 2H 2 O) Dissolved in 25ml of double distilled water, stirred for 6 minutes, then continued to stir, and quickly injected 1.25ml of 0.025mol / L sodium borohydride (NaBH 4 ), and stirred for 10 minutes. Cu-Pt alloy hollow nanoparticles were prepared by current displacement method, that is, 4.8ml of 0.1×10 -3 mol / L chloroplatinic acid. Then, after stirring and reacting for 15 minutes, the solution was reacted statically at room temperature (14±2°) for 36 hours. The Au electrode was polished on the chicken skin, rinsed repeatedly with twice distilled water, ultrasonicated in an ultrasonic cleaner with a power of 120 watts for 8 minutes, placed in PBS with a pH of 7.0, and activated by cyclic voltammetry scanning for 12 laps for use. Centrifuge at a rotational speed of 12000r / min for 20 minutes, and repeatedly wash with double distilled water to completely remove remaining unreacted su...

Embodiment 3

[0036] First, 50 μl of 0.1mol / L CuCl 2 With 70μl of 0.1mol / L sodium citrate (C 6 h 5 o 7 Na 3 2H 2 O) be dissolved in 30ml of double distilled water, after stirring for 8 minutes, then continue to stir, inject 1.5ml 0.025mol / L sodium borohydride (NaBH 4 ), and stirred for 15 minutes. Cu-Pt alloy hollow nanoparticles were prepared by current displacement method, that is, 5.4ml of 0.1×10 -3 mol / L chloroplatinic acid. Then, after stirring and reacting for 20 minutes, the solution was reacted statically at room temperature (14±2°) for 32 hours. The Au electrode was polished on the chicken skin, rinsed repeatedly with double distilled water, ultrasonicated for 10 minutes in an ultrasonic cleaner with a power of 120 watts, and then placed in PBS with a pH of 7.0 and activated by cyclic voltammetry scanning for 15 cycles for use. Centrifuge at a rotational speed of 12000r / min for 18 minutes, and repeatedly wash with double distilled water to completely remove remaining unreac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com