Slag powder-doped composition for preparing white facing as-cast finish concrete

The technology of fair-faced concrete and slag powder is applied in the field of the composition field of preparing white-faced fair-faced concrete mixed with slag powder, which can solve the problem that fly ash does not have its own hydration and hardening characteristics, the concrete itself shrinks greatly, and the slump is long. To solve problems such as large loss in time, to achieve the effect of scientific and reasonable component ratio, compact concrete, and ensure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

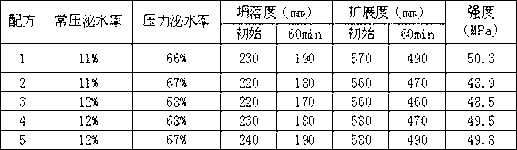

Examples

Embodiment Construction

[0030] Prepare each component of white C40 finish fair-faced concrete composition as follows:

[0031] ⑴. The cement is P.W42.5 white Portland cement produced by Aalborg Portland (Anqing) Co., Ltd. Main indicators: whiteness greater than 87, initial setting time not earlier than 45min, final setting time not later than 10h, and stability qualified. It meets the quality requirements of GBT2015-2005 "White Portland Cement" standard.

[0032] (2) The slag powder adopts S95 grade slag powder produced by Ningxia Boyu Cement Co., Ltd., the main indicators: specific surface area ≥ 400 kg / m2, activity index 7d ≥ 75%, loss on ignition ≤ 3.0%, chloride ion content ≤ 3.0%, in line with GB / T18046-2008 "Granulated Blast Furnace Slag Powder Used in Cement and Concrete" standard requirements.

[0033] ⑶. The sand adopts the middle sand of Wuzhong Gaozha in Ningxia Autonomous Region, with uniform color, fineness modulus 2.6, good gradation, mud content < 3%, and mud content < 1%, which co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com