Production method for glycolic acid ester

A glycolic acid ester and production method technology, applied in the direction of carboxylate preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of low selectivity of glycolic acid ester, achieve less side reactions, lower temperature, lower The effect of loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare the catalyst according to the content of 20 parts of Cu, 5 parts of Ag and 2 parts of Fe and the silicon oxide of the remainder, and its steps are as follows: (a) configure the mixed nitrate solution and sodium carbonate solution of copper, silver and iron of required concentration; (b) Co-precipitate the above solution at 70°C, stir continuously during the precipitation process, and pH=6 when the precipitation terminates; (c) Repeatedly wash the above precipitation slurry with deionized water until there is no Na + After adding silicon oxide carrier (specific surface area 150 square meters / gram) and concentration are 10% silica sol binding agent beating; Spherical shape; (e) Dry at 120°C for 6 hours and bake at 450°C for 4 hours. That is, the fluidized bed catalyst A was prepared.

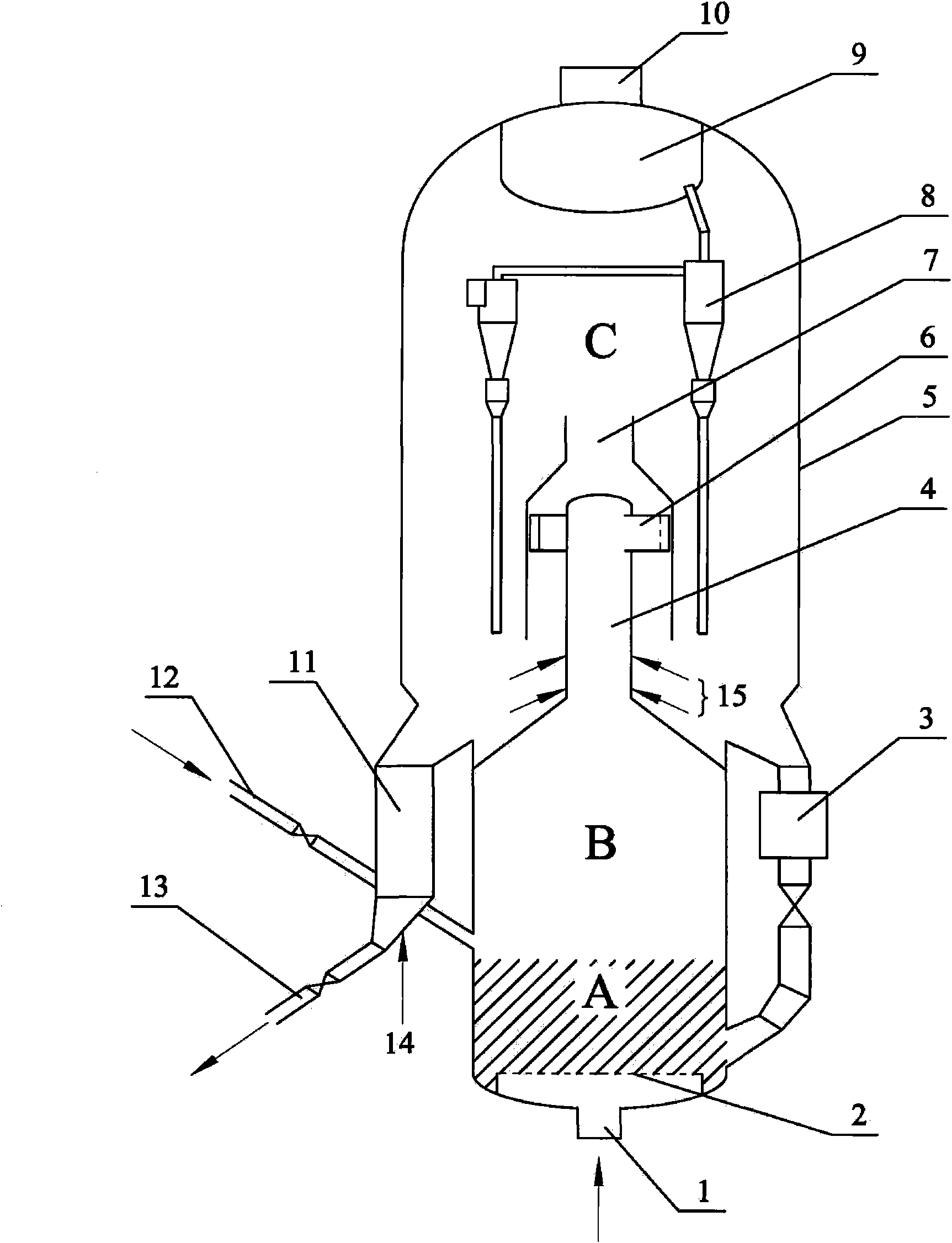

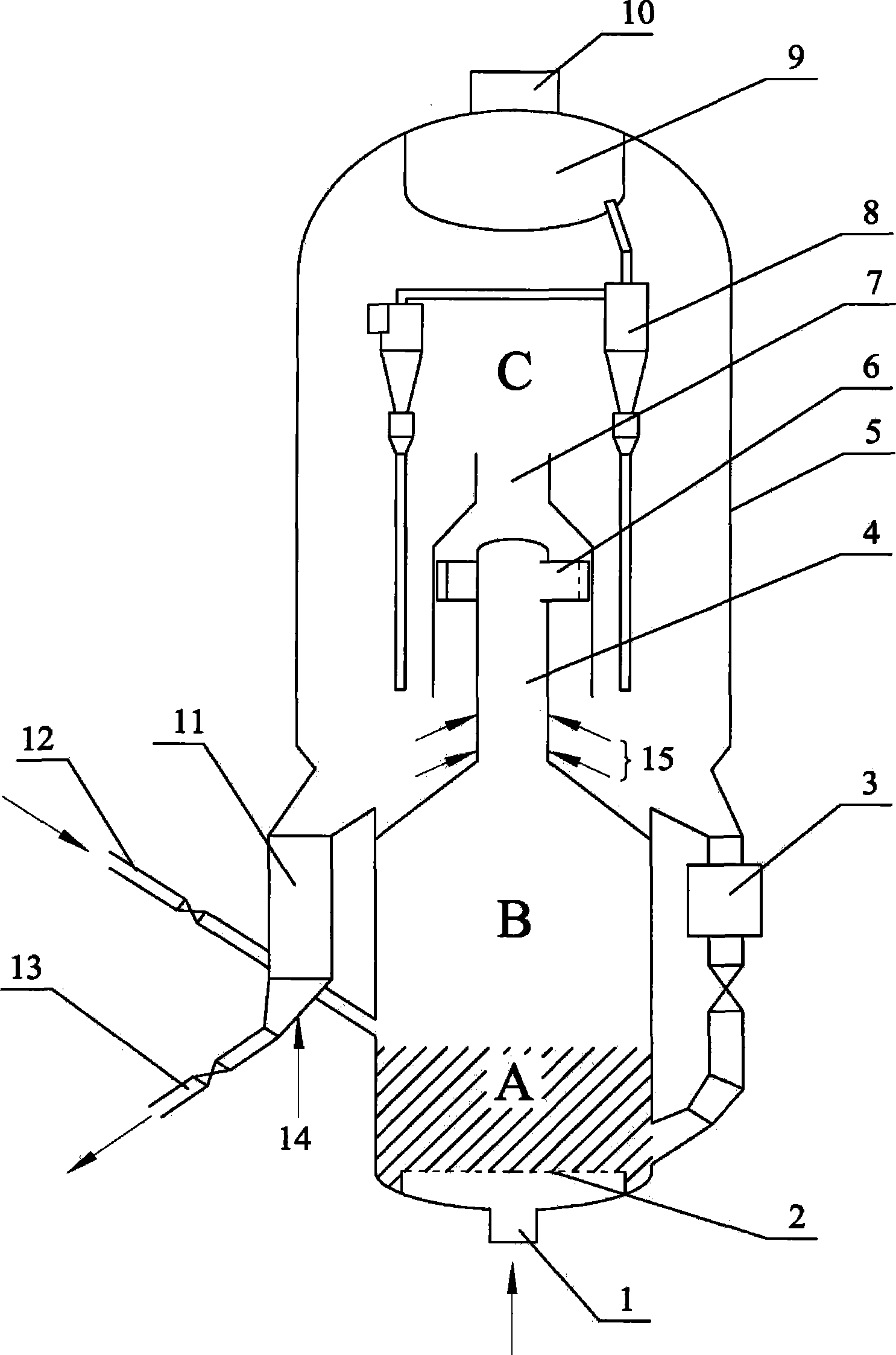

[0022] The test is attached figure 1 The fluidized bed reactor device shown, using dimethyl oxalate as raw material, the reaction temperature is 200 ° C, the weight space velocity...

Embodiment 2

[0024] According to the various steps and conditions of [Example 1], the average diameter of the catalyst particles is 150 microns when the catalyst is molded, the particles are spherical, and the average specific surface area of the carrier is 280 square meters per gram. The catalyst B thus obtained is 30 parts of Cu, 10 parts of Ag, 1 part of Fe and the rest of silicon oxide. The test is attached figure 1 The fluidized bed reactor device shown, using dimethyl oxalate as raw material, the reaction temperature is 170 ° C, the weight space velocity is 0.5 hours -1 , the hydrogen / ester molar ratio is 80:1, and the reaction pressure is under the condition of 2.8MPa, the raw material is contacted with the catalyst, and the reaction generates the effluent containing methyl glycolate, and the reaction result is: the transformation rate of dimethyl oxalate is 82 %, the selectivity of glycolate was 83%.

Embodiment 3

[0026] Prepare the catalyst according to the content of 40 parts of Cu, 3 parts of Ag and 15 parts of Fe and the silicon oxide and aluminum oxide of the balance, and its steps are as follows: (a) prepare the mixed nitrate solution and carbonic acid of copper, silver and iron of required concentration Sodium solution; (b) the above solution is co-precipitated at 65°C, stirring continuously during the precipitation process, and the pH=7 when the precipitation terminates; (c) repeatedly washing the above precipitation slurry with deionized water until there is no Na+ After adding alumina carrier (specific surface area 300 square meters / gram) and concentration are 15% silica sol binding agent beating; Spherical shape; (e) Dry at 120°C for 6 hours and bake at 450°C for 4 hours. That is, a fluidized bed catalyst C is obtained.

[0027] The test is attached figure 1 The fluidized bed reactor device shown, using dimethyl oxalate as raw material, the reaction temperature is 150°C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com