Degradable PC (Poly Carbonate)/PLA (Poly Lactic Acid) alloy and preparation method thereof

A technology of alloy and polycarbonate, which is applied in the field of degradable PC/PLA alloy and its preparation, can solve the problems that the toughness and heat resistance cannot meet the requirements of engineering plastics, and the comprehensive performance of PLA is not as good as that, so as to improve the heat resistance , good processing fluidity and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The degradable PC / PLA alloy of the embodiment of the present invention can adopt same preparation method, comprises the following steps:

[0050] (1) Pretreatment of raw materials;

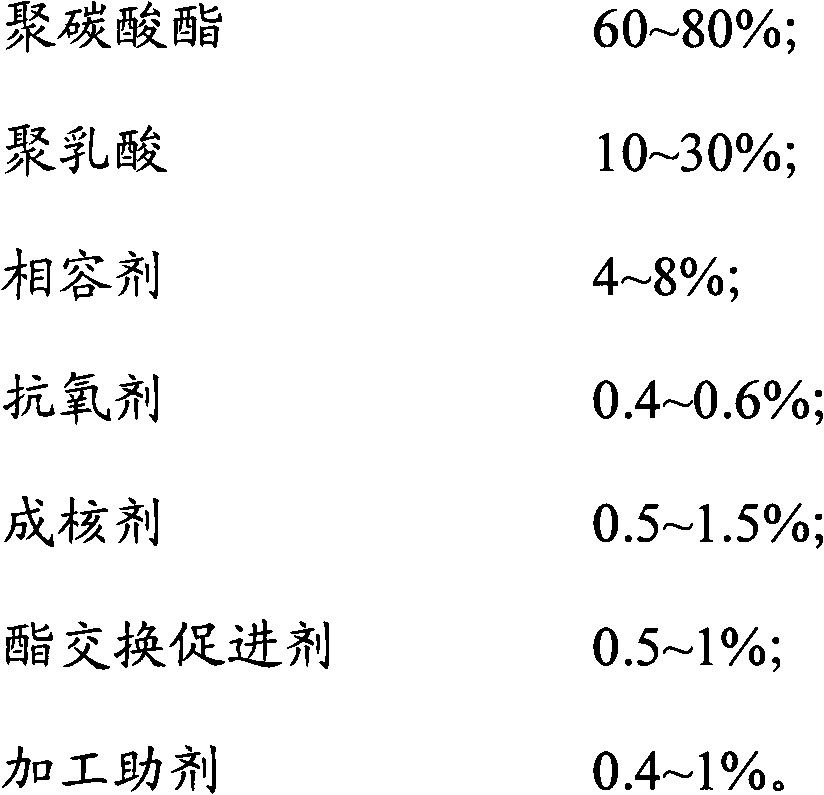

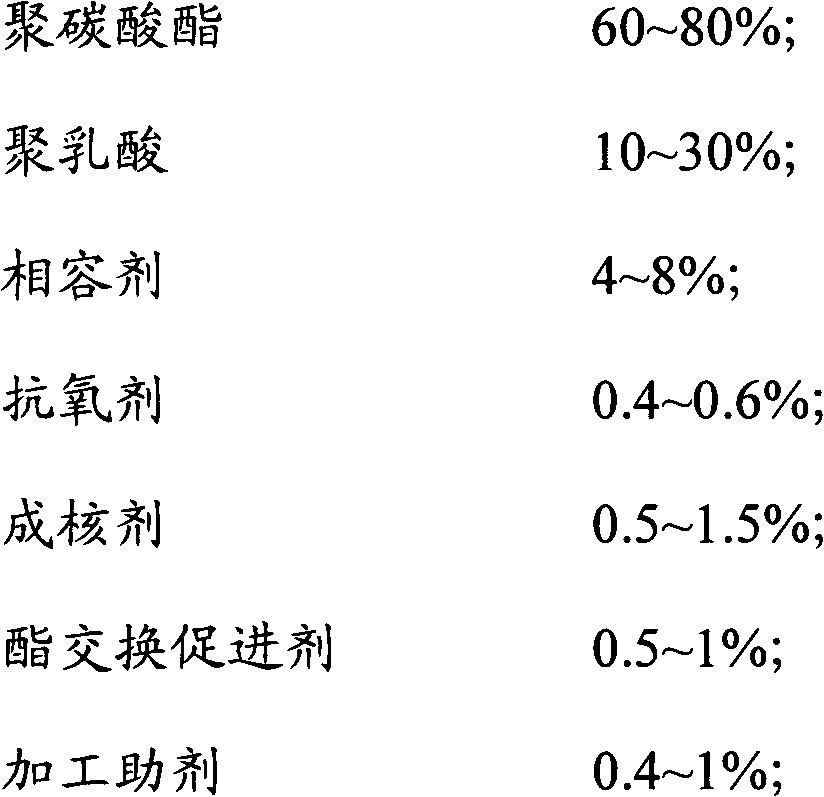

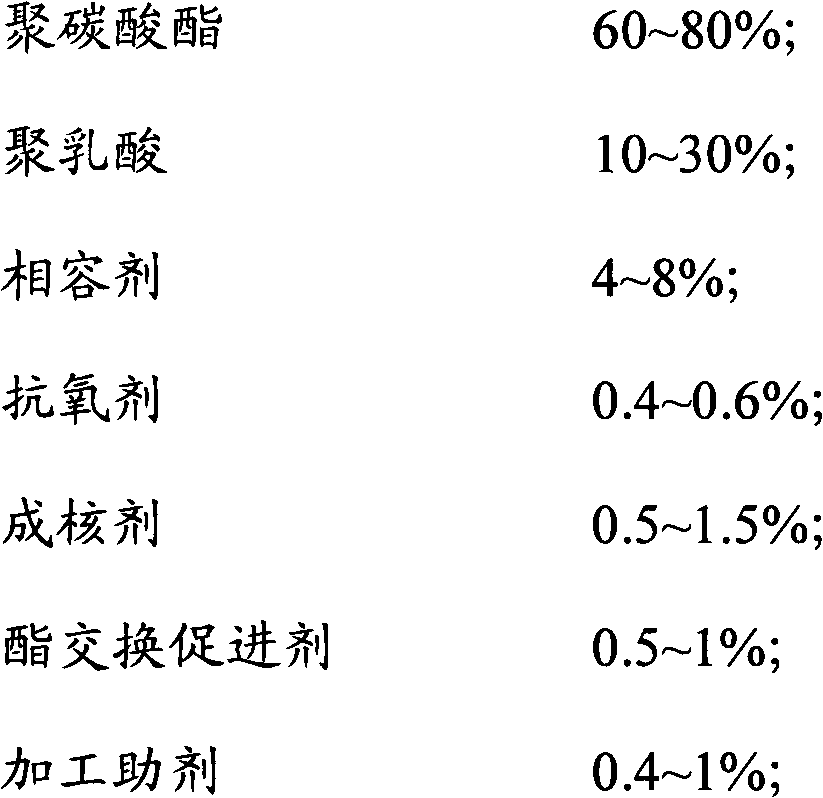

[0051] (2) Take each component according to the following weight percentages:

[0052]

[0053] (3) Mix all the raw materials taken by weighing;

[0054] (4) Add the mixed raw materials into a parallel twin-screw extruder, melt and extrude, and granulate.

[0055] Twin-screw machines are generally divided into the following parts: feeding system, gearbox, main motor, screw, barrel, heating system, vacuum system, cooling system, interlock control system, and electrical control system. Among them, in the temperature control section of the heating system, it is divided into the feeding area, the first area, the second area, the third area, and the fourth area.

[0056] Among them, the process conditions of the melting stage of the parallel twin-screw extruder in the embodiment of the prese...

Embodiment 1

[0058] (1) Pretreatment of raw materials: PC and PLA were dried separately, the drying temperature of PC was 110°C for 4 hours; the drying temperature of PLA was 60°C for 5 hours. The remaining materials were dried at 80°C for 6 hours;

[0059] (2) Weigh PC 73.5kg, PLA 20kg, EMA-GMA 4kg, antioxidant 10100.2kg, antioxidant 1680.2kg, lubricant TAF 0.6kg, transesterification accelerator tetrabutyl titanate 0.5kg, nucleating agent p-tert-butylcalix[8]arene 1kg;

[0060] (3) All the raw materials weighed were mixed in a high-speed mixer for 20 minutes;

[0061] (4) Put the uniformly mixed material into the hopper of the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, water-cool, air-dry, pelletize, and finally pack into PC / PLA alloy finished products.

[0062] The above PC / PLA alloy was injected into a standard sample, and the test performance is shown in Table 1.

Embodiment 2

[0064] (1) Pretreatment of raw materials: PC and PLA were dried separately, the drying temperature of PC was 110°C for 4 hours; the drying temperature of PLA was 60°C for 5 hours. The remaining materials were dried at 80°C for 6 hours;

[0065] (2) Weigh 60kg of PC, 30kg of PLA, 4kg of EMA-GMA, 10760.2kg of antioxidant, 1680.2kg of antioxidant, 0.6kg of lubricant TAF, 0.4kg of PETS, and 1kg of tetrabutyl titanate as a transesterification accelerator. Nucleating agent p-tert-butylcalix[8]arene 1.5kg;

[0066] (3) All the raw materials weighed were mixed in a high-speed mixer for 20 minutes;

[0067] (4) Put the uniformly mixed material into the hopper of the twin-screw extruder, melt, blend and extrude through the twin-screw extruder, water-cool, air-dry, pelletize, and finally pack into PC / PLA alloy finished products.

[0068] The above PC / PLA alloy was injected into a standard sample, and the test performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com