Cimetidine instant granules and preparation method thereof

A technology of cimetidine and granules, applied in the field of cimetidine instant granules and their preparation, can solve the problems of animal body stress response, unfavorable disease treatment, poor palatability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

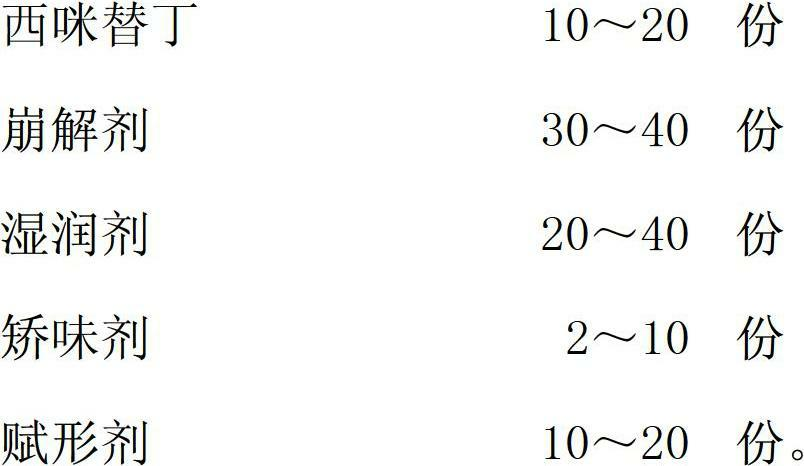

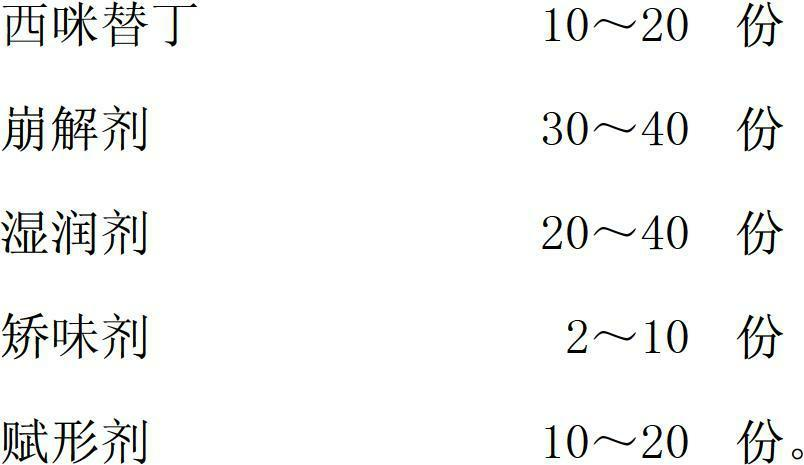

preparation example Construction

[0024] The preparation method of above-mentioned cimetidine instant granule, comprises the following steps:

[0025] (1) mix cimetidine with disintegrating agent, pass through 80 mesh sieves after pulverizing;

[0026] (2) Dissolving the wetting agent in purified water;

[0027] (3) After mixing the correctives and excipients, pass through an 80-mesh sieve, then add to the product of step (1), and mix evenly;

[0028] (4) the product of step (3) is mixed with the product of step (2);

[0029] (5) Wet granulation, and then dry at 60-70 degrees Celsius to obtain the finished product.

Embodiment 1

[0031] (1) 10 grams of cimetidine are mixed with 40 grams of sucrose, crushed and passed through an 80-mesh sieve;

[0032] (2) 10 grams of polyvinylpyrrolidone and 20 grams of polyethylene glycol 6000 were dissolved in 20 milliliters of purified water;

[0033] (3) After mixing 5 grams of sodium bicarbonate, 5 grams of malic acid, and 10 grams of microcrystalline cellulose, after passing through an 80-mesh sieve, add in the product of step (1), and mix evenly;

[0034] (4) the product of step (3) is mixed with the product of step (2);

[0035] (5) Wet granulation, after drying, sizing and packaging, the finished product is obtained.

[0036] The active ingredient content of the prepared cimetidine instant granule is: 10%.

Embodiment 2

[0038] (1) 15 grams of cimetidine are mixed with 35 grams of soluble starch, crushed and passed through an 80-mesh sieve;

[0039] (2) 20 grams of tartaric acid and 10 grams of polyvinylpyrrolidone are dissolved in 20 milliliters of purified water;

[0040] (3) After mixing 5 grams of sodium bicarbonate, 5 grams of fruit flavor, and 10 grams of microcrystalline cellulose, after passing through an 80-mesh sieve, add it to the product of step (1), and mix evenly;

[0041] (4) the product of step (3) is mixed with the product of step (2);

[0042] (5) Wet granulation, after drying, sizing and packaging, the finished product is obtained.

[0043] The active ingredient content of the prepared cimetidine instant granule is: 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com