Technology and device for preparing industrial carbon monoxide with water gas

A carbon monoxide and gasification device technology, applied in the field of chemical technology, can solve the problems of insufficient utilization of CO, high raw material prices, large energy consumption, etc., and achieves the effect of saving raw materials, long operation period and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

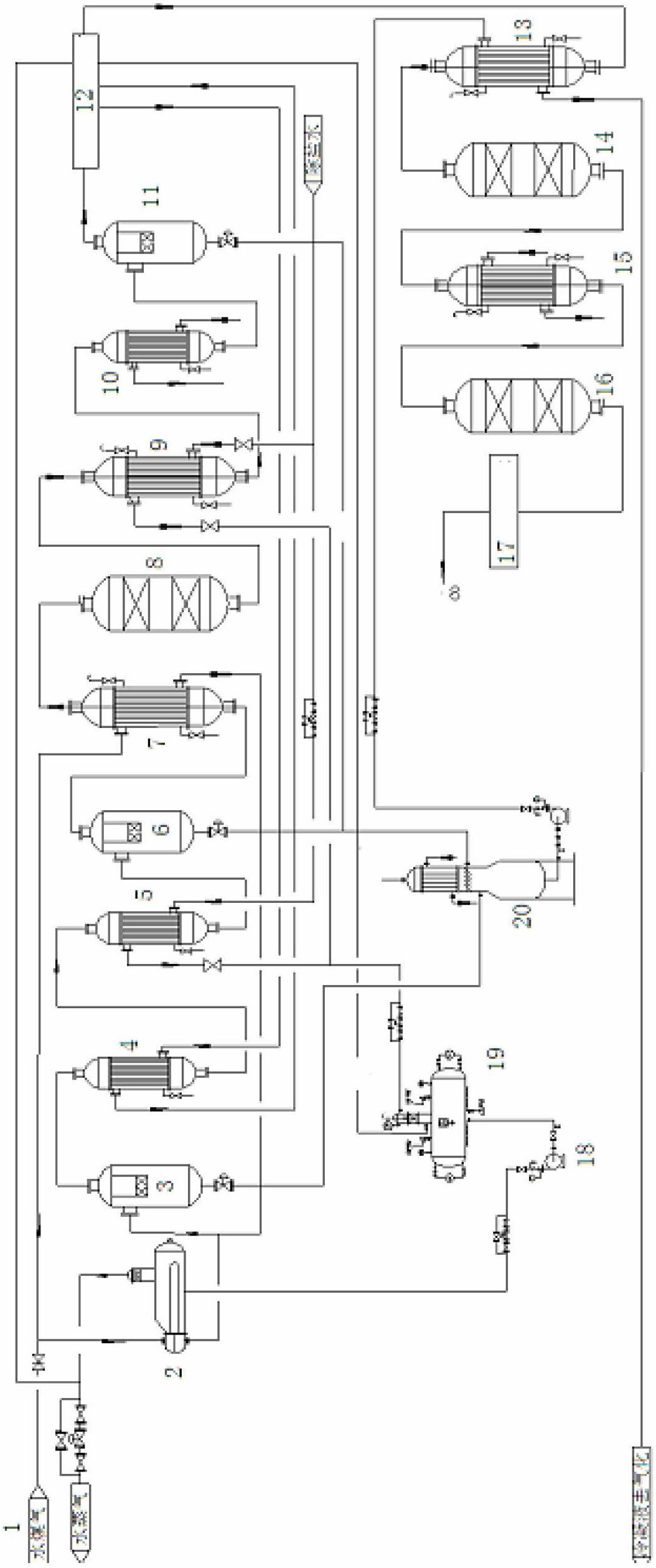

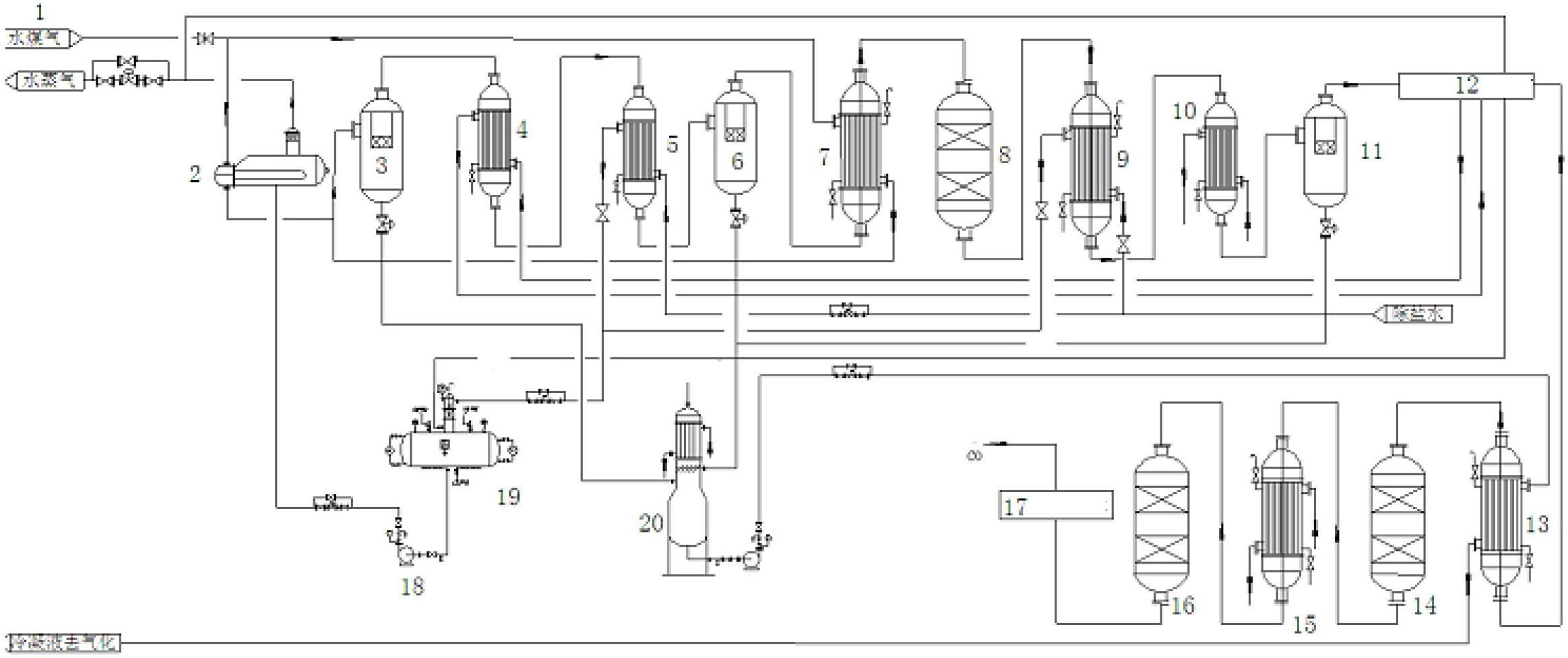

Image

Examples

Embodiment 1

[0026] A kind of technology that water gas prepares industrial carbon monoxide, comprises steps as follows:

[0027] (1) The water gas produced by the coal-water slurry gasification device recovers heat through the waste heat boiler, and the water-gas ratio in the water gas is controlled to reach 0.3, and then the water gas is separated from gas and liquid to exchange heat with the solvent in the NHD gas purification, and then Heat exchange with desalinated water, after heat exchange, the gas is separated from gas and liquid again, and heat exchange with water gas;

[0028] (2) After the heat exchange, the water gas is reheated to 150°C and enters the organic sulfur hydrolysis reactor I to generate COS+H 2 O=H 2 S+CO 2 The organic sulfur is converted into inorganic sulfur, and the water gas converted by organic sulfur is exchanged with desalted water and circulating water respectively, and hydrogen sulfide and carbon dioxide are removed through the NHD gas purification proce...

Embodiment 2

[0032] A kind of technology that water gas prepares industrial carbon monoxide, comprises steps as follows:

[0033] (1) The water gas produced by the coal-water slurry gasification device recovers heat through the waste heat boiler, and the water-gas ratio in the water gas is controlled to reach 0.5, and then the water gas is separated from gas and liquid to exchange heat with the solvent in NHD gas purification , and then exchange heat with desalinated water, after the heat exchange, the gas is separated from gas and liquid again, and exchange heat with water gas;

[0034] (2) After the heat exchange, the water gas is reheated to 170°C and enters the organic sulfur hydrolysis reactor I to generate COS+H 2 O=H 2 S+CO 2 The organic sulfur is converted into inorganic sulfur, and the water gas converted by organic sulfur is exchanged with desalted water and circulating water respectively, and hydrogen sulfide and carbon dioxide are removed through the NHD gas purification proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com