Method for controlling morphology and performance of ferriferrous oxide

A technology of ferroferric oxide and morphology, applied in the field of inorganic materials, to achieve the effects of concentrated particle size distribution, high purity, and strong product controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

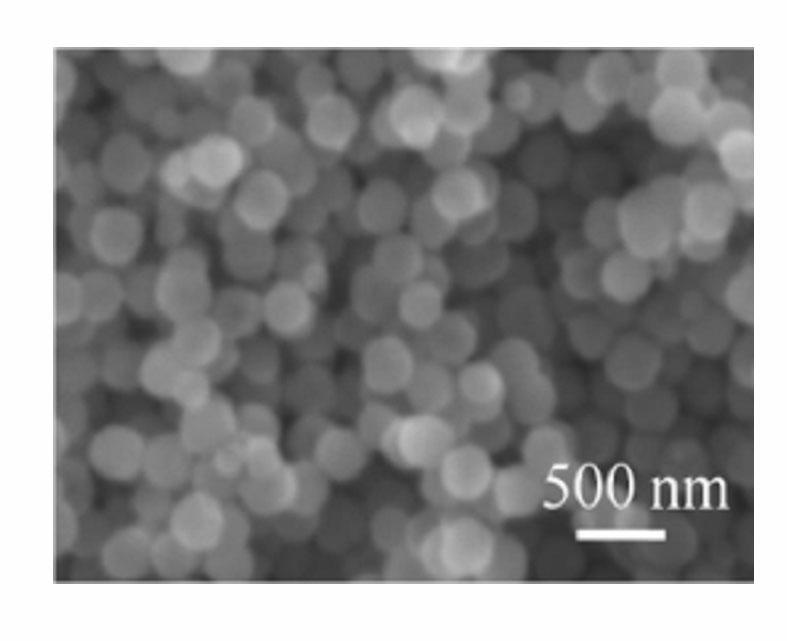

[0025] According to the preparation process, 1.2 g FeCl 3 ·6H 2 O and 0.834 g of tetrabutylammonium chloride were added to 30 mL of ethylene glycol, and magnetically stirred to completely dissolve ferric chloride hexahydrate and tetrabutylammonium chloride to obtain a clear solution. 3.6 g of urea was added to the above clear solution, and under the action of magnetic stirring, it was fully mixed to obtain a reddish-brown clear solution. The solution was sealed and placed in a polytetrafluoroethylene-lined reactor with a volume of 50 mL, and the reactor was placed in an oven, heated to 180 °C, and reacted for 36 h. After the reaction, the obtained black precipitate was washed by centrifugation with deionized water and absolute ethanol three times, and then dried at 60°C for 12 h to obtain ferric oxide particles. Scanning electron microscope observation and magnetic performance test results see figure 1 . The characterization shows that the morphology of the product is sphe...

Embodiment 2

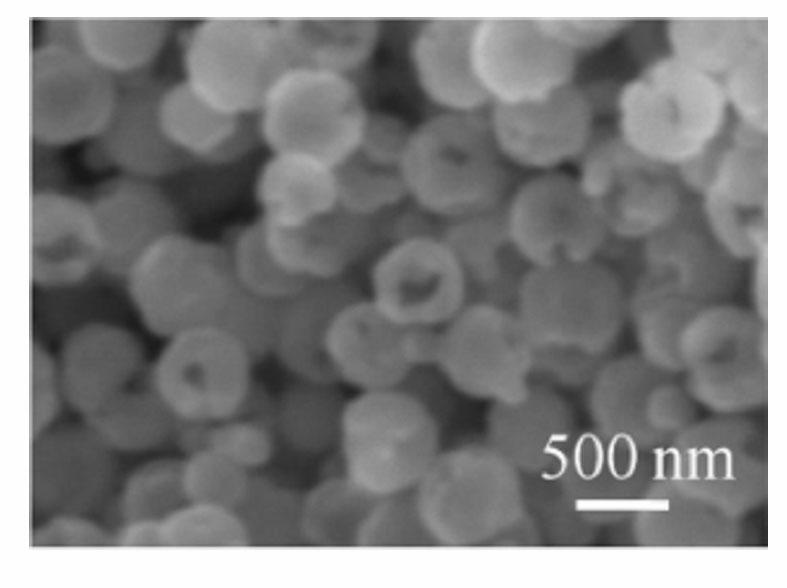

[0027] According to the preparation process, 1.2 g FeCl 3 ·6H 2 O and 0.834 g of tetrabutylammonium chloride were added to 30 mL of ethylene glycol, and magnetically stirred to completely dissolve ferric chloride hexahydrate and tetrabutylammonium chloride to obtain a clear solution. 3.6 g of urea was added to the above clear solution, and under the action of magnetic stirring, it was fully mixed to obtain a reddish-brown clear solution. The solution was sealed and placed in a polytetrafluoroethylene-lined reactor with a volume of 50 mL, and the reactor was placed in an oven, heated to 220 °C, and reacted for 36 h. After the reaction, the obtained black precipitate was washed by centrifugation with deionized water and absolute ethanol three times respectively, and then dried at 60°C for 12 h to obtain ferric oxide particles. Scanning electron microscope observation and magnetic performance test results see figure 2 . The characterization shows that the morphology of the p...

Embodiment 3

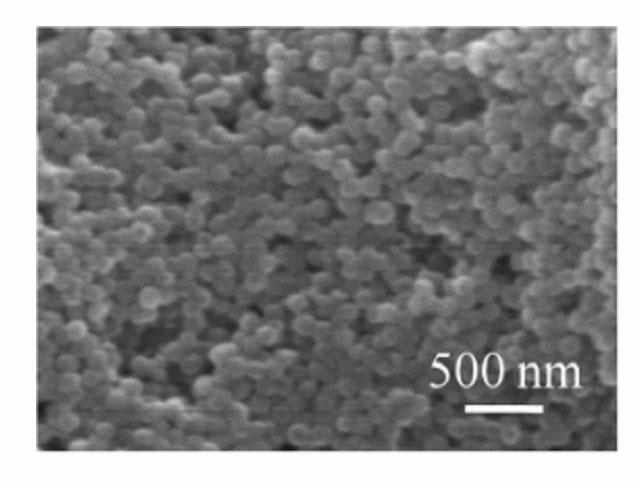

[0029] According to the preparation process, 1.2 g FeCl 3 ·6H 2 O and 0.834 g of tetrabutylammonium chloride were added to 30 mL of ethylene glycol, and magnetically stirred to completely dissolve ferric chloride hexahydrate and tetrabutylammonium chloride to obtain a clear solution. 3.6 g of urea was added to the above clear solution, and under the action of magnetic stirring, it was fully mixed to obtain a reddish-brown clear solution. The solution was sealed and placed in a polytetrafluoroethylene-lined reactor with a volume of 50 mL, and the reactor was placed in an oven, heated to 200 °C, and reacted for 8 h. After the reaction, the obtained black precipitate was washed by centrifugation with deionized water and absolute ethanol three times respectively, and then dried at 60°C for 12 h to obtain ferric oxide particles. Scanning electron microscope observation and magnetic performance test results see image 3 . The characterization shows that the morphology of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com