Industrial wastewater treatment method during diosgenin production process

A production process, turmeric saponin technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of waste water not being discharged up to standard, and achieve break The chain degradation and cell metabolism speed up, the process scheme is improved, and the effect of reducing the concentration of organic matter in the effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

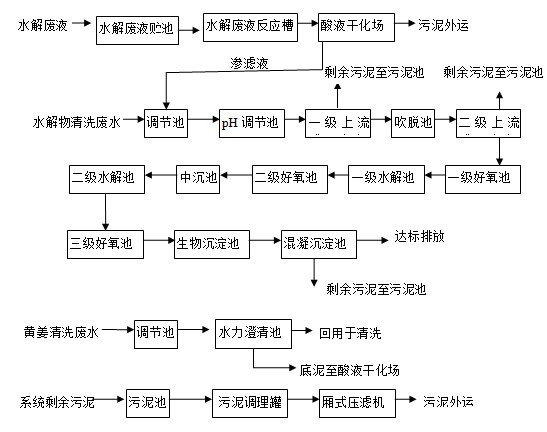

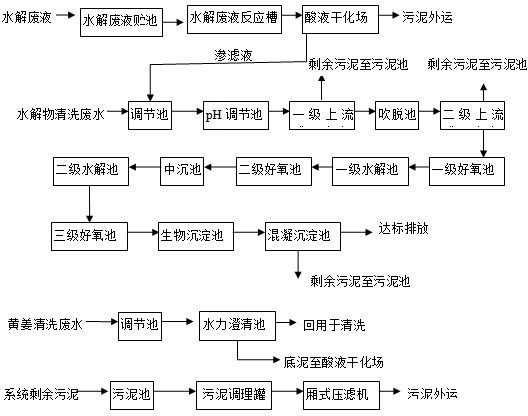

Method used

Image

Examples

Embodiment

[0064] (1) Hydrolysis waste liquid pretreatment system

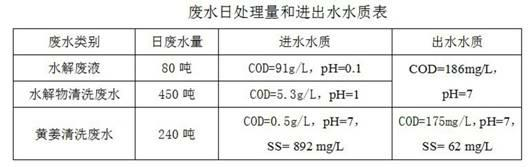

[0065] 1) The hydrolysis waste liquid produced in the production process of turmeric saponin enters the hydrolysis waste liquid storage tank, the residence time is 10 hours, the water volume of the hydrolysis waste liquid is 80 tons / day, the COD is 91g / L, and the pH value is 0.1.

[0066] ) The waste water in the hydrolysis waste liquid storage tank is pumped to the first-stage hydrolysis waste liquid reaction tank, and the neutralizing agent CaO is added for neutralization until the pH value is 7, and then enters the second-stage hydrolysis waste liquid reaction tank, and flocculation is added Dosage of PAM is 2mg / L, and the residence time is 50 minutes. The reaction tank is equipped with a stirring device to accelerate the reaction.

[0067] ) The hydrolysis waste liquid after neutralization, including the gypsum and lime residue generated by the neutralization reaction, is discharged into the acid liquid dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com