High-molecular fluorescent microsphere with controllable emission wavelength and preparation method thereof

A technology of emission wavelength and fluorescent microspheres, which is applied in the field of preparation of fluorescent sensing materials, can solve problems such as difficult processing and molding, poor device stability, etc., and achieve the effects of stable properties, guaranteed stability, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

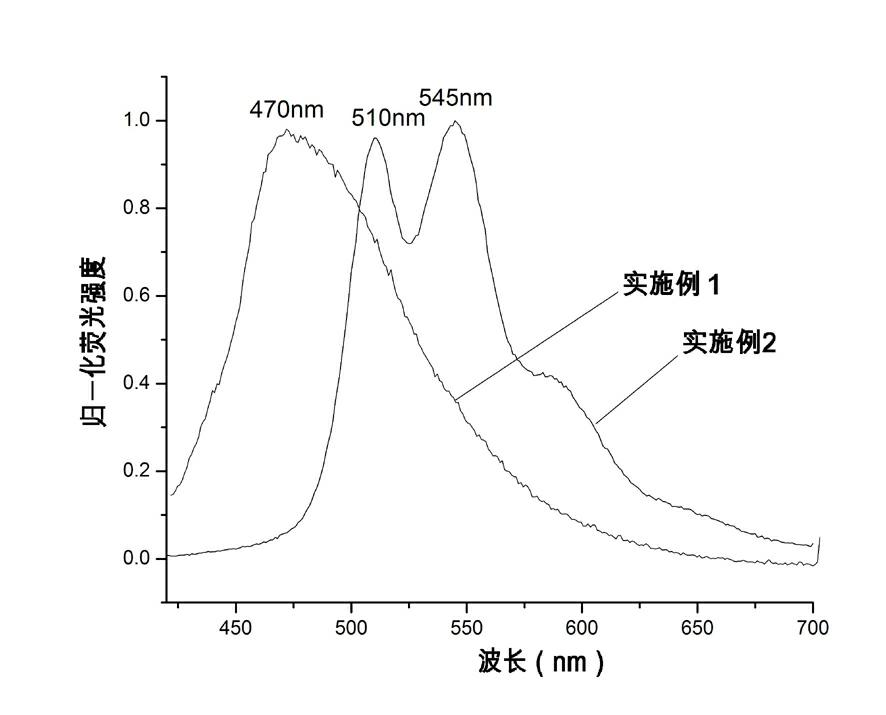

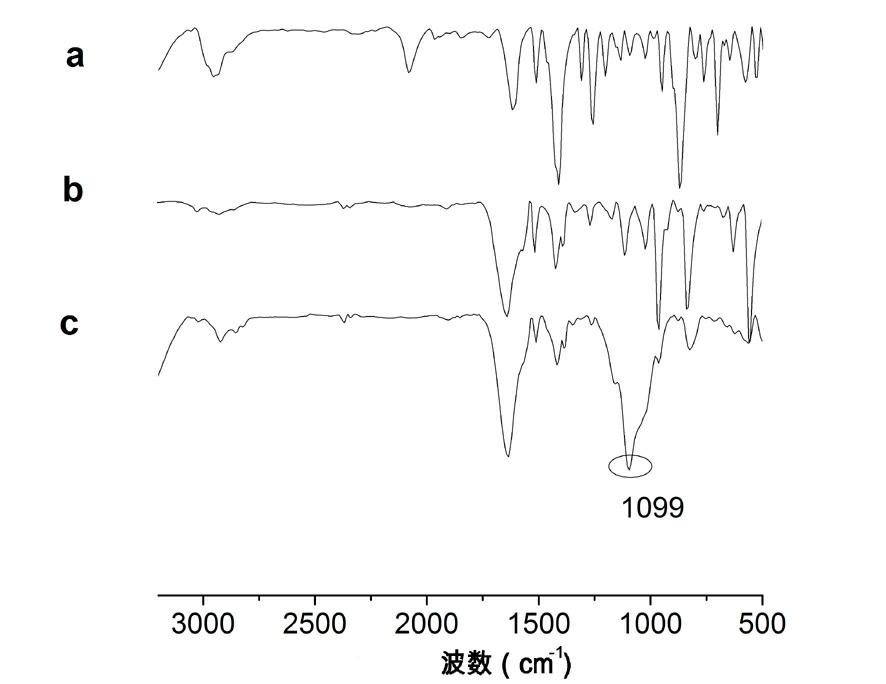

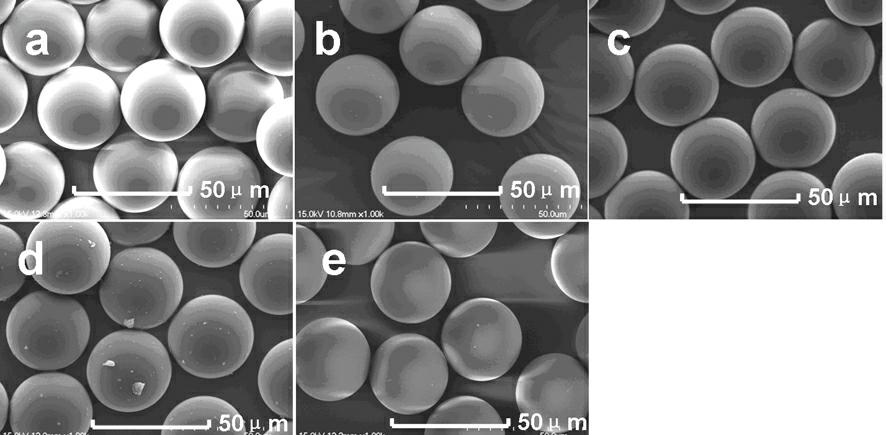

Embodiment 1

[0028] 1. The PPV precursor solution was prepared by using the salt precursor method: 0.6895 g (1.965 mMol) of polymerized monomer without side chains was dissolved in 12 mL of H 2 O, then slowly add 1.7 mL NaOH aqueous solution into it, stir in an ice-water bath for 1 hour, add 3 mL of 2 M HCl solution to terminate the reaction, and then dialyze with a 3500 DA pore size dialysis bag for 1 day (2×500 mL deionized water H 2 (0) to obtain 20 mL of PPV precursor solution;

[0029] 2. Mix 4 mL of the precursor solution obtained in step 1 with 28 mL of methanol solution. The reaction is carried out under anhydrous and oxygen-free conditions at a reaction temperature of 50°C. After 22 hours of reaction, the methanol is completely removed under reduced pressure to obtain about 3.5mL poly(p-phenylene vinylene) precursor solution containing methoxy group;

[0030] 3. Mix 3 mL of the solution described in step 2 with 0.3 g of sulfonated polystyrene microspheres, shake for 1 hour, cent...

Embodiment 2

[0035] 1. Mix 3 mL of poly(p-phenylene) precursor solution with 0.3 g of sulfonated polystyrene microspheres, shake for 1 hour, centrifuge, remove the supernatant, add 8 mL of deionized water to the microspheres and shake for 1 hour , centrifuge and remove the supernatant. Then use the same volume of deionized water and the same volume of absolute ethanol to wash once according to the above steps, and dry thoroughly under vacuum to obtain poly-p-styrene precursor-coated microspheres;

[0036]2. Add the microspheres obtained in step 1 into 3 mL of xylene solution, and add 0.2 mL of triethylamine, and the reaction is carried out under anhydrous and oxygen-free conditions. The reaction was shaken at 120°C for 3 hours. After the solution was cooled, 5 mL of acetone was added, centrifuged, and the supernatant was removed. 8 mL of acetone was added to the microspheres for shaking for 1 hour, and the supernatant was removed by centrifugation. Then wash once with the same volume of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com