Oil-in-water type crude oil emulsification viscosity reducer and preparation method thereof

An emulsification and viscosity reduction, oil-in-water technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost and complex synthesis process, and achieve the requirements of mineral salt resistance, simple synthesis operation, and resistance to ore. The powerful effect of salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

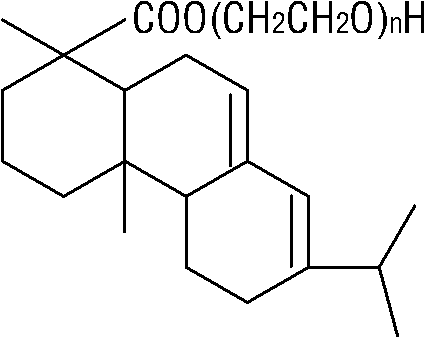

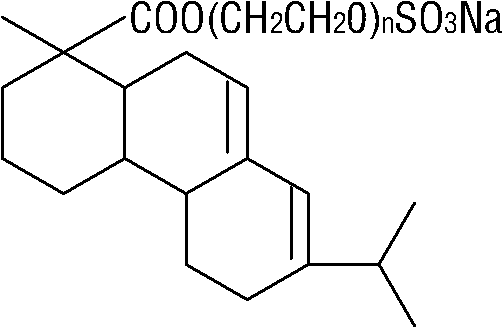

Image

Examples

Embodiment 1

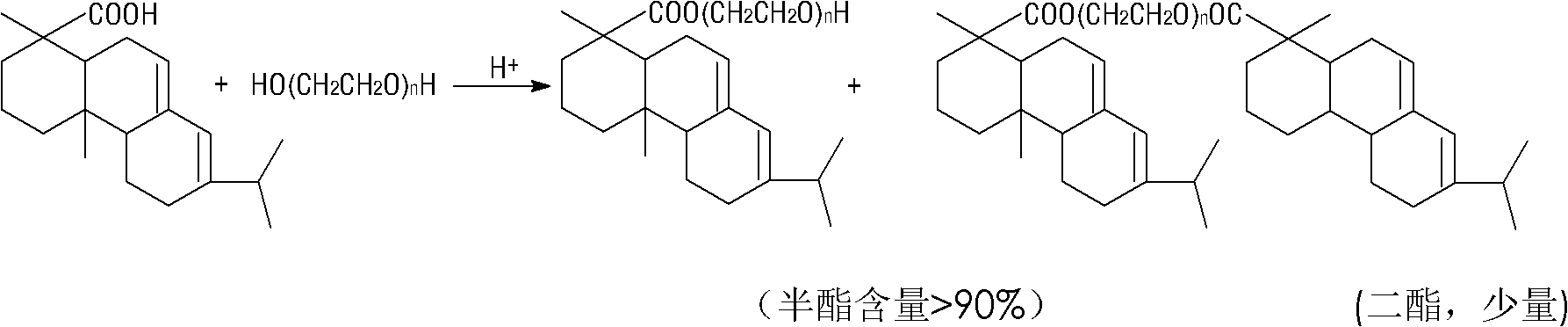

[0041] (1) Preparation of abietic acid polyethylene glycol (1000) half ester. The composite operation is:

[0042] Add successively in the reaction flask with stirrer, water separator and thermometer: 24g through pulverized special-grade rosin, 80g polyethylene glycol (relative molecular weight 1000), use N 2 Purge the reaction bottle; heat and melt rapidly and keep stirring, when the temperature of the reaction bottle rises to about 200°C, add 1.0g of phosphorous acid, continue to heat up to the system temperature of 280°C, react at this temperature, use the water separator to continuously move In addition to the water produced by the reaction, the reaction was completed in about 2 hours. Cool the reaction system to 30-40° C. to obtain a light yellow paste of abietic acid polyethylene glycol (1000) half ester. The n value is 23. .

[0043] (2) Preparation of abietic acid polyethylene glycol (1000) sulfate. The composite operation is:

[0044] 60g of abietic acid polyeth...

Embodiment 2

[0048] (1) Preparation of abietic acid polyethylene glycol (2000) half ester. The composite operation is:

[0049] Add successively in the reaction flask with stirrer, water separator and thermometer: 24g through pulverized special-grade rosin, 160g polyethylene glycol (relative molecular weight 2000), use N 2 Purge the reaction bottle; heat it under constant stirring, when the temperature of the reaction bottle rises to about 200°C, add 1.0g of phosphorous acid, continue to heat up to the system temperature of 285°C, react at this temperature, and use the water separator to continuously remove The water produced by the reaction was completed in about 2 hours. Cool the reaction system to 30-40° C. to obtain a light yellow semi-wax abietic acid polyethylene glycol (2000) half ester. The product n value was 46.

[0050] (2) Preparation of abietic acid polyethylene glycol (2000) sulfate. The composite operation is:

[0051] 60g rosin acid polyethylene glycol (2000) half este...

Embodiment 3

[0056] ① Weigh 0.1g, 0.2g, 0.3g, 0.4g and 0.5g of the viscosity reducer prepared in Example 1, and make 0.1% by mass, 0.2% by mass, 0.3% by mass, 0.4% by mass and 0.5% by mass of the viscosity reducer respectively Viscosity aqueous solution; ②Add 49mL of hot viscous oil and 21mL of viscosity reducer aqueous solution of various concentrations to five sets of 100mL colorimetric tubes respectively, ultrasonically oscillate at 50°C for 30min, and age in an oven at 50°C for 4 hours;③ Draw 15mL of the aged emulsion and inject it into the Brookfield rotary drum viscometer, adjust the temperature of the rotor water bath to 50°C, preheat for 20min, and measure the viscosity of the emulsion μ e , mPa.s; ④ Measure the viscosity μ of heavy oil at the same temperature 0 , mPa.s. ⑤ Calculate the viscosity reduction rate η.

[0057] η(%)=[(μ 0 -μ e ) / μ 0 ]×100

[0058] Following the same procedure as above, the viscosity reducing efficiency of the viscosity reducing agent prepared in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com