Preparation method of ruthenium complex-silica nanoparticles

A technology of silica and nanoparticles, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve problems such as troublesome surface functionalization of fluorescent silica nanoparticles, and achieve good monodispersity and high fluorescence intensity , size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

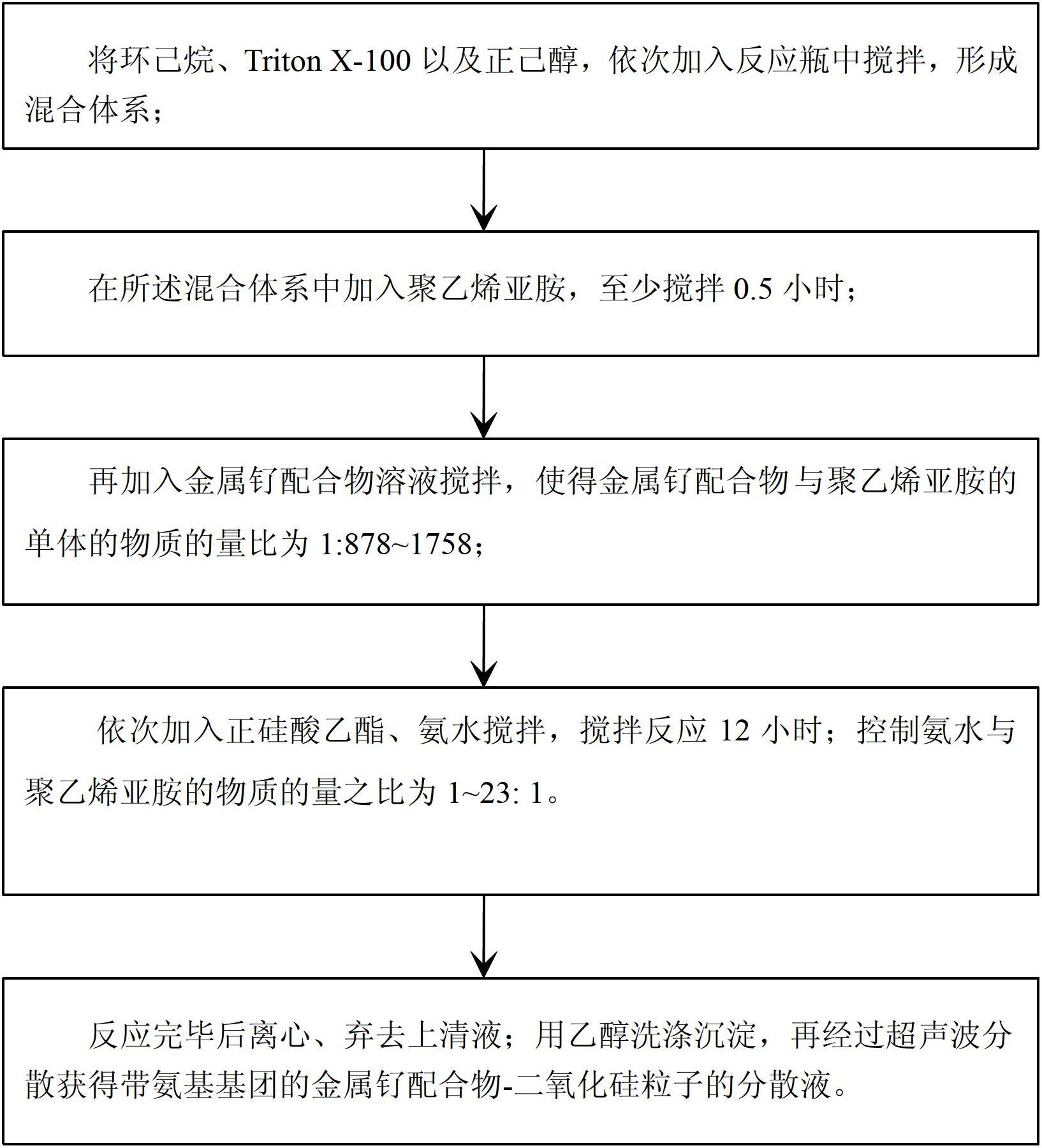

[0026] combine figure 1 The production flow of this embodiment is illustrated as shown.

[0027] Step 1: Dissolve an appropriate amount of tris(disulfonic acid-4,7-diphenyl-phenanthroline) ruthenium (II) tetrasodium salt (RuBPS) in deionized water to prepare a negatively charged metal ruthenium complex An aqueous solution of RuBPS with a concentration of 5.5 mg / ml.

[0028] Step 2: Take 7.5ml of cyclohexane (analytical pure), 1.806ml of Triton X-1006ml with a concentration of 0.1mol / L, and 2.64ml of n-hexanol (analytical pure) as the dispersed phase, surfactant and co-surfactant respectively Add it into the reaction flask and stir evenly to form a mixed system.

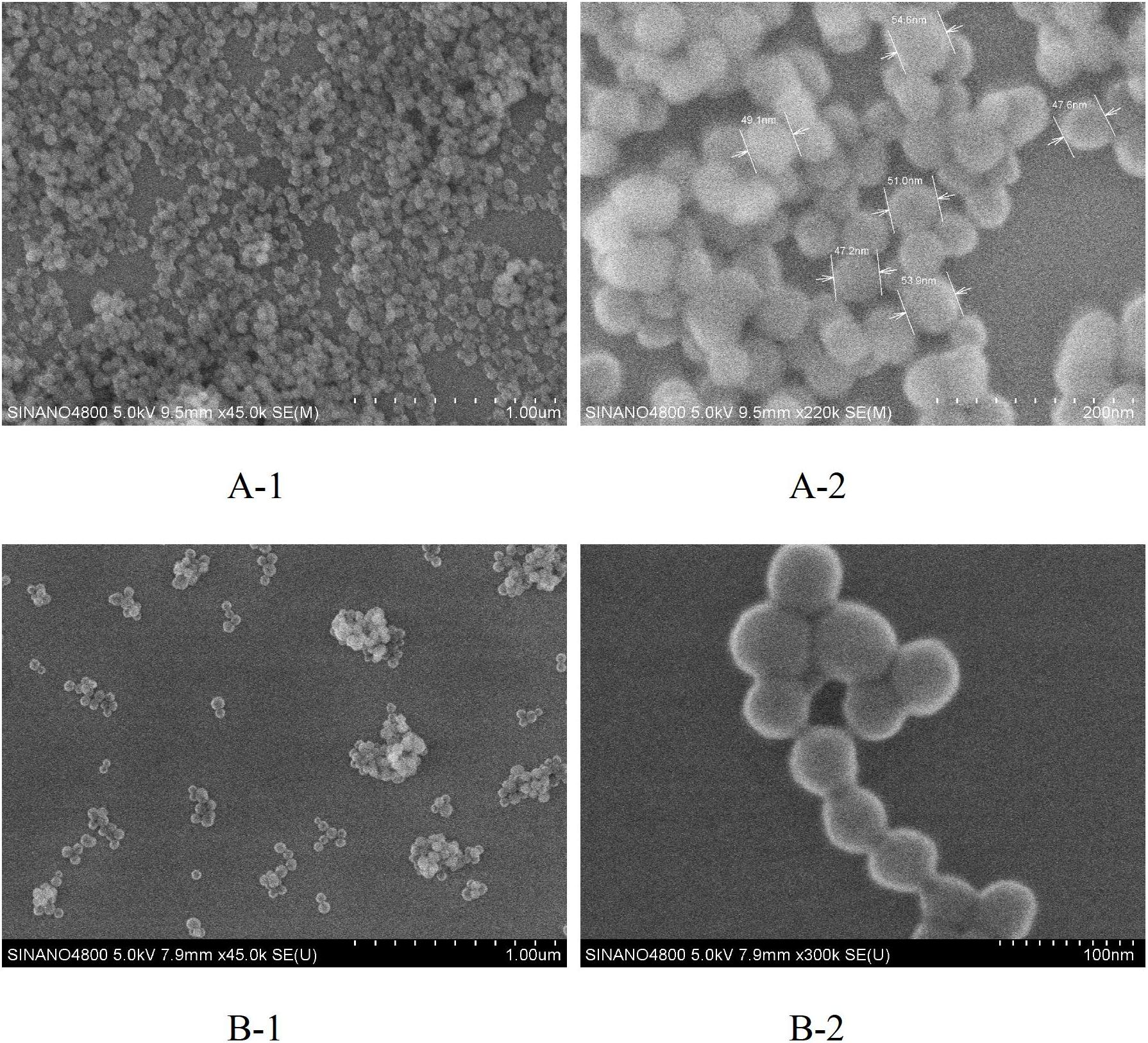

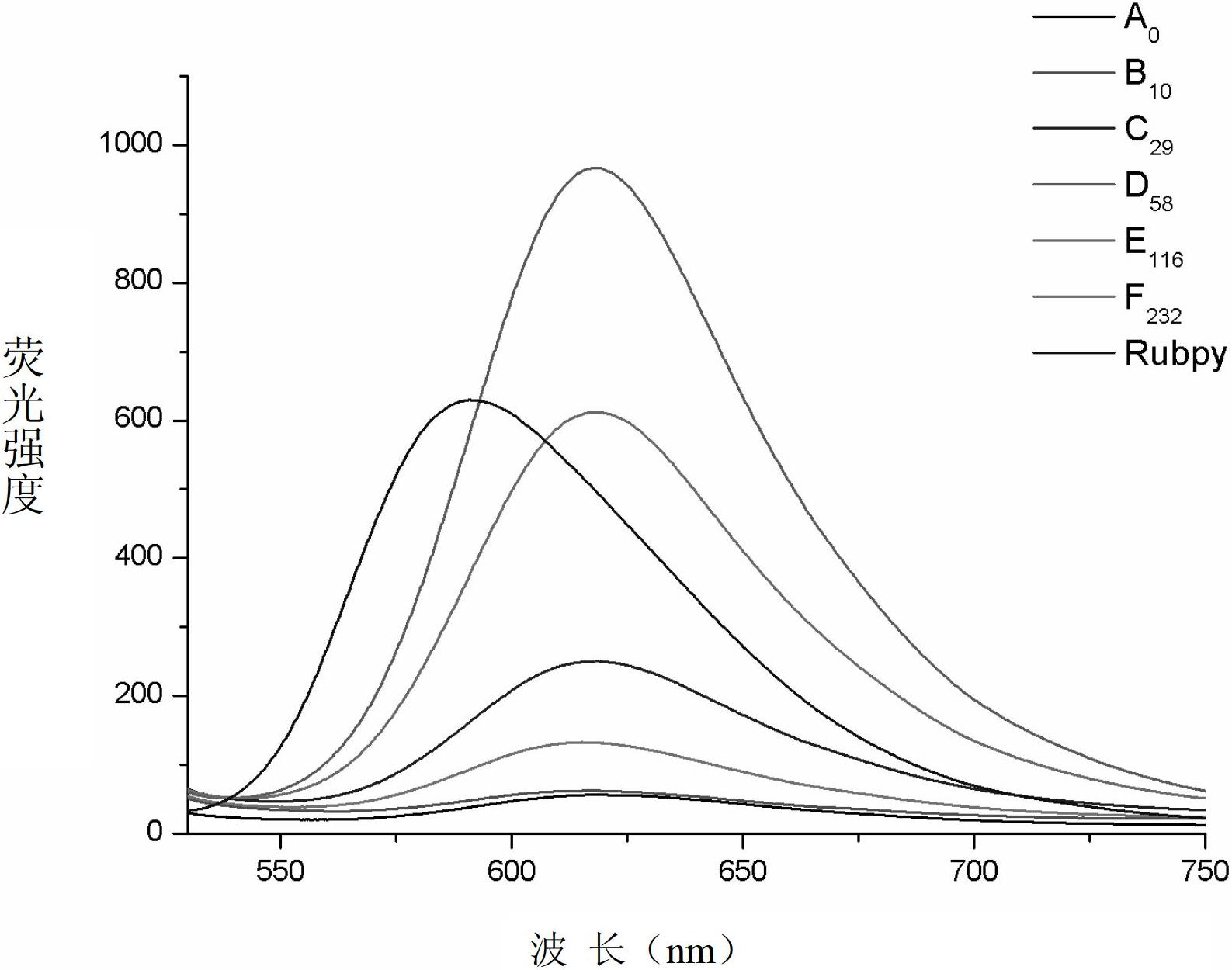

[0029] Step 3: Add 100 ul of a polyethyleneimine (PEI) aqueous solution with a concentration of 29 mmol / L to the above system, and stir at a constant speed for 0.5 hours. Then add 0.1 ml of the above-mentioned RuBPS aqueous solution, and stir well. Among them, PEI serves as a catalyst to provide a positive center ...

Embodiment 2

[0033] Step 1: Dissolve an appropriate amount of RuBPS in deionized water to prepare an aqueous solution containing negatively charged metal ruthenium complex RuBPS at a concentration of 5.5 mg / ml.

[0034] Step 2: Take 7.5ml of cyclohexane (analytical pure), 1.806ml of Triton X-1006ml with a concentration of 0.1mol / L, and 2.64ml of n-hexanol (analytical pure), respectively as the dispersed phase, surfactant, and cosurfactant in sequence Add to the reaction bottle and stir well. Wherein, the ratio of the amount of the surfactant to the co-surfactant is preferably controlled between 2.7 and 8.

[0035] Step 3: Add 100 ul of PEI aqueous solution with monomer amine concentration of 58 mmol / L to the above system, and stir at a constant speed for 0.5 hour. Then add 0.1 ml of the above-mentioned RuBPS aqueous solution, and stir well. Among them, PEI serves as a catalyst to provide a positive center to adsorb the negatively charged fluorescent molecule RuBPS, so that it can be embe...

Embodiment 3

[0039] In this example, other steps and the amount of reactants used are consistent with Example 1, except that the concentration of PEI monomer is 0 mmol / L. Finally, RuBPS-silica nanoparticles (A0) with amino groups were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com