Spandex fiber with excellent chlorine resistance, and preparation method thereof

A technology of spandex fiber and manufacturing method, which is applied in the direction of rayon manufacturing, fiber chemical characteristics, single-component polyurethane rayon, etc., can solve the problems such as the chlorine resistance of spandex fiber that has not been found, and achieve excellent discoloration resistance and chlorine resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In a nitrogen stream, 518g of diphenylmethane-4,4'-diisocyanate and 2328g of polytetramethylene ether glycol (molecular weight: 1800) were reacted at 90°C for 95 minutes while stirring to obtain two Isocyanate-terminated polyurethane prepolymers. After cooling the prepolymer to room temperature, 4269 g of dimethylacetamide was added to dissolve it, thereby preparing a polyurethane prepolymer solution.

[0053] In the next step, 43 g of ethylenediamine and 9.1 g of diethylamine were dissolved in 1,889 g of dimethylacetamide, and added to the above prepolymer solution at a temperature below 9° C. to prepare a polyurethane solution. The following ingredients are added as additives for mixing: 1% by weight of poly(N,N-diethyl-2-aminoethyl acrylate methyl ester) as a color fastness enhancer relative to the solid content of the polymer; 0.1% 0.26% by weight of magnesium stearate as an unwinding improver; and 4% of hydrotalcite Mg as a chlorine resistant agent 4 Al 2 (OH) ...

Embodiment 2

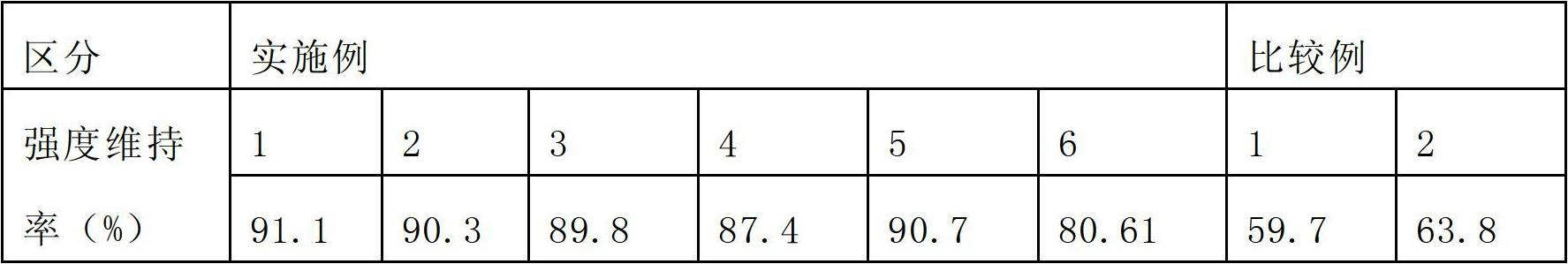

[0059] Use 3,3',3",5,5',5"-hexa-tetra-butyl-a,a',a"-(mesitylbenzene-2,4 , 6-triyl) three-p-cresol, except above-mentioned this point, other all utilize the polymkeric substance identical with embodiment 1 to manufacture spandex fiber, and detect chlorine resistance, record the result in following table 1 .

Embodiment 3

[0061] Tetrakis[methylene-2-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]methane was used as a symmetrical double hindered phenolic compound, and 4% by weight of Uncoated hydrotalcite Mg 4 Al 2 (OH) 12 CO 3 ·3H 2 O, except for the above point, others all utilize the same polymer as in Example 1 to produce spandex fibers, and detect chlorine resistance, and record the results in the following Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com