Production method of fish protein hydrolyzed chelate

A chelate and fish protein technology, which is applied in the field of preparation of fish protein hydrolyzed chelate, can solve the problems of low antibacterial and low utilization, and achieve the effects of low production cost, antibacterial effect and good antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

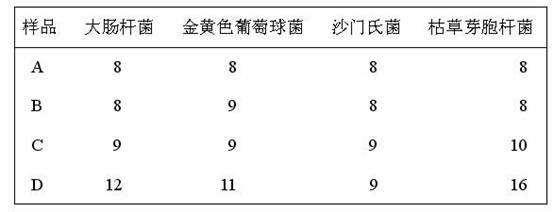

Embodiment 1

[0044] a) Raw material processing: hairtail leftovers, head, tail, and bone removed, and the fish meat is reserved for use;

[0045] b) Pre-treatment: wash the fish meat obtained in step a with clean water, drain the water, shred it, homogenize it at room temperature, and store it in a freezer;

[0046]c) Compound enzyme hydrolysis: Add deionized water to the fish pulp obtained in step b in a weight ratio of 3 times, adjust the pH to 6.8, add compound enzyme, hydrolyze at 45°C, the weight of the compound enzyme is 0.5% of the fish pulp, and the compound enzyme consists of Composed of flavor enzyme and papain, the weight ratio of flavor enzyme to papain is 1:3, the hydrolysis time is 4 hours, after the hydrolysis, keep in boiling water for 10 minutes to kill the enzyme, after cooling, suction filtration, then centrifugal filtration, and finally ultrafiltration Membrane filtration removes hydrolyzate with a molecular weight lower than 10kDa, collects the ultrafiltered hydrolyzat...

Embodiment 2

[0049] a) Raw material processing: hairtail leftovers, head, tail, and bone removed, and the fish meat is reserved for use;

[0050] b) Pre-treatment: wash the fish meat obtained in step a with clean water, drain the water, shred it, homogenize it at room temperature, and store it in a freezer;

[0051] c) Compound enzyme hydrolysis: Add deionized water to the fish pulp obtained in step b by 2 times the weight ratio, adjust the pH to 6.0, add compound enzyme, hydrolyze at 40°C, the weight of the compound enzyme is 0.2% of the fish pulp, and the compound enzyme is composed of Composed of flavor enzyme, papain and neutral protease, the weight ratio of flavor enzyme, papain and neutral protease is 1:3:2, the hydrolysis time is 1.5 hours, after hydrolysis, keep in boiling water for 8 minutes to kill the enzyme, after cooling Suction filtration, then centrifugal filtration, and finally ultrafiltration membrane filtration to remove hydrolyzate with a molecular weight lower than 10kD...

Embodiment 3

[0054] a) Raw material processing: hairtail leftovers, head, tail, and bone removed, and the fish meat is reserved for use;

[0055] b) Pre-treatment: wash the fish meat obtained in step a with clean water, drain the water, shred it, homogenize it at room temperature, and store it in a freezer;

[0056] c) Compound enzyme hydrolysis: Add deionized water to the fish pulp obtained in step b at a weight ratio of 5 times, adjust the pH to 7.0, add compound enzyme, and hydrolyze at a temperature of 50°C. The weight of the compound enzyme is 0.8% of the fish pulp, and the compound enzyme consists of Composition of papain and neutral protease. The weight ratio of papain and neutral protease is 3:2. The hydrolysis time is 6 hours. Ultrafiltration membrane filtration removes hydrolyzate with a molecular weight lower than 10kDa, and the ultrafiltration hydrolyzate is collected and stored at 4°C;

[0057] d) Polypeptide chelate preparation: adjust the pH of the ultrafiltration hydrolyza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com