Method for preparing graphene magnetic nanometer composite materials

A magnetic nano-composite material technology, applied in chemical instruments and methods, medical preparations with inactive ingredients, pharmaceutical formulations, etc., can solve the problems of easy failure and weak bonding of composite materials, and achieve easy separation and less environmental pollution. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

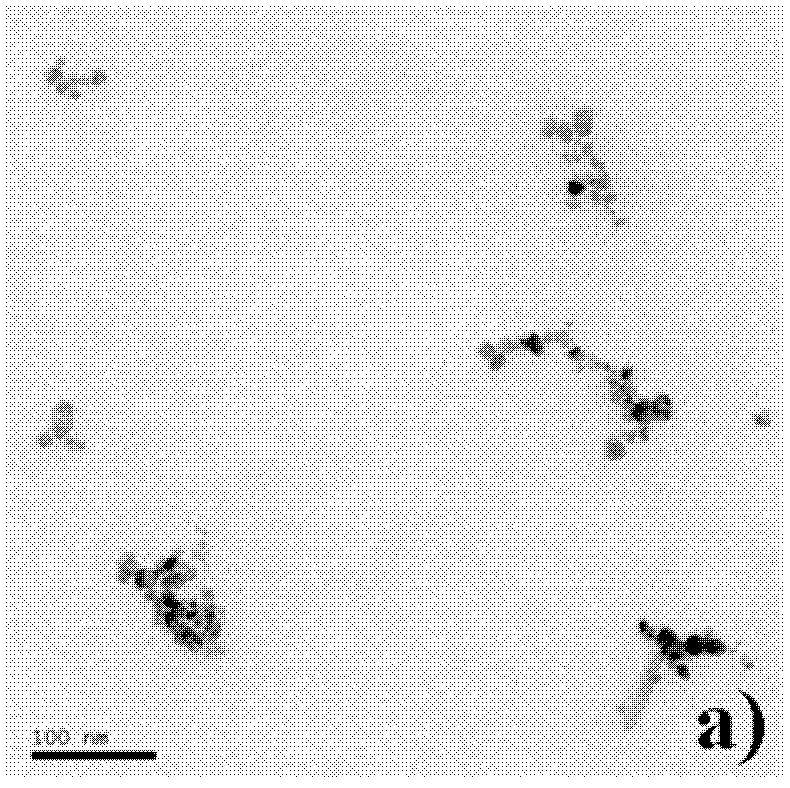

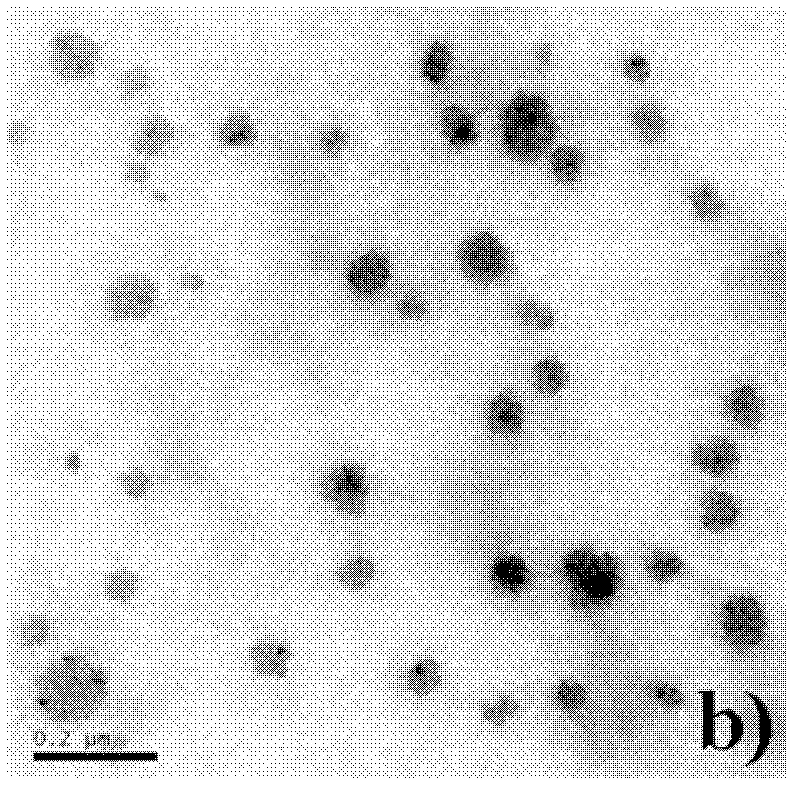

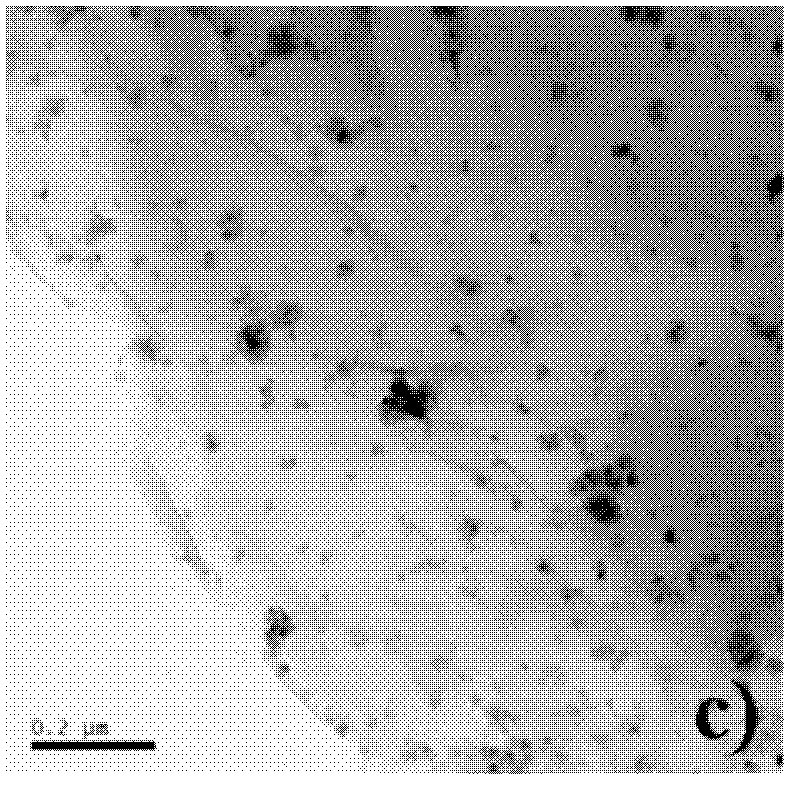

Image

Examples

Embodiment 1

[0019] 1) 3.135g Fe·Cl 2 4H 2 O, 8.514g FeCl 3 ·6H 2 O was added to 100 mL of water, mixed with 12.7 mL of NaOH solution with a concentration of 10 mol / L, stirred at room temperature for 1 h, transferred to a water bath at 90°C and continued to stir for 1 h, added 0.33 mL of concentrated nitric acid with a mass concentration of 69.8%, continued to stir for 0.5 h, and then Add 50 mL of 0.3 mol / L sodium citrate solution, stir for 0.5 h, wash with absolute ethanol for 3 times after cooling, separate and collect the product Fe 3 o 4 And put it in an oven at 80°C to dry for later use;

[0020] 2) Mix 160mL of absolute ethanol and 40mL of water, add 0.1g of Fe prepared in step 1) 3 o 4 , mixed and stirred, adding 5mL of ammonia water with a mass concentration of 30%, the above solution was ultrasonically treated with a power of 100W for 1h to clarify, and 500μL of 3-aminopropyltriethoxysilane was added dropwise while stirring, and used after 12h of reaction Wash with absolute...

Embodiment 2

[0024] 1) 3.00g FeCl 2 4H 2 O, 10.00g FeCl 3 ·6H 2 O was added to 150 mL of water, mixed with 15.0 mL of NaOH solution with a concentration of 20 mol / L, stirred at room temperature for 3 h, transferred to a water bath at 65°C and continued to stir for 3 h, added 0.3 mL of concentrated nitric acid with a mass concentration of 69.8%, continued to stir for 2 h, and then Add 100 mL of 0.5 mol / L sodium citrate solution, stir for 2 hours, wash with absolute ethanol for 5 times after cooling, separate and collect Fe 3 o 4 And put it in an oven at 80°C to dry for later use;

[0025] 2) Mix 200mL of absolute ethanol and 50mL of water, add 0.3g of Fe prepared in step 1) 3 o 4 , mix and stir, add 10mL of ammonia water with a mass concentration of 20%, and ultrasonically treat the above solution with a power of 80W for 3h until clarified, add 800μL tetraethoxysilane dropwise while stirring, and wash it with absolute ethanol for 4 times after reacting for 18h , separate and collect ...

Embodiment 3

[0029] 1) 5.00g FeCl 2 4H 2 O, 8.00g FeCl 3 ·6H 2O was added to 200 mL of water, mixed with 12.0 mL of NaOH solution with a concentration of 30 mol / L, stirred at room temperature for 5 h, transferred to a water bath at 60°C and continued to stir for 5 h, added 1.0 mL of concentrated nitric acid with a mass concentration of 69.8%, continued to stir for 3 h, and then Add 150 mL of 1.0 mol / L sodium citrate solution, stir for 3 h, wash with absolute ethanol for 4 times after cooling, and separate the collected product Fe 3 o 4 And put it in an oven at 80°C to dry for later use;

[0030] 2) Mix 150mL of absolute ethanol and 30mL of water, add 0.5g of Fe prepared in step 1) 3 o 4 , mix and stir, add 8 mL of ammonia water with a mass concentration of 40%, and ultrasonically treat the above solution with a power of 50W for 5 hours until clarification, add 1000 μL of polyethyleneimine dropwise while stirring, and wash it with absolute ethanol for 5 times after reacting for 48 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com