Preparation method of nano photochemical catalytic oxidizer for removing arsenic (III) in drinking water

A nano-light, drinking water technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxidized water/sewage treatment, etc., to achieve the effects of easy storage, convenient transportation, and improved economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

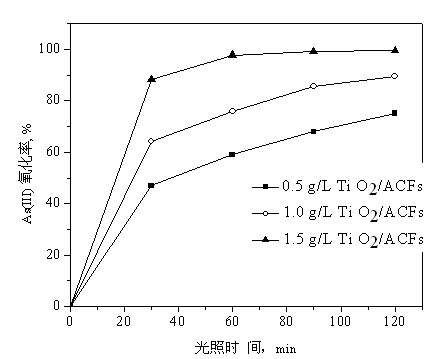

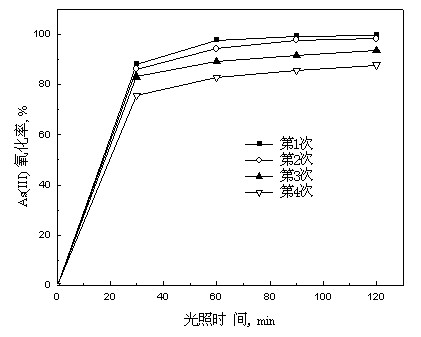

Image

Examples

Embodiment 1

[0027] The selected material is: the selected pore volume is 0.503 cm 3 / g activated carbon fiber, monoalcohol (C 1 -C 6 ), low-carbon polyol series (C 1 -C 10 ), acetylacetone, glacial acetic acid, deionized water, inert gas (common), etc.

[0028] The specific steps are:

[0029] (1) Select a commercially available pore volume of 0.503 cm 3 / g of activated carbon fiber material, boiled in boiling water (deionized water) for 3 h, and ultrasonically treated for 60 min;

[0030] (2) At room temperature, in a 250 mL three-neck flask equipped with a magnetic stirrer, activated carbon fiber, and a dropping funnel, add 20 mL tetrabutyl titanate dissolved in 40 mL absolute ethanol, and add 10 mL dropwise under magnetic stirring. mL acetylacetone and 15 mL glacial acetic acid, then add a mixture of 80 mL absolute alcohol solution and 15 mL water.

[0031] (3) Ultrasonic oscillation for 2 h after the addition was completed, and then stand still for 48 h.

[0032] (4) Weigh 15 ...

Embodiment 2

[0037] The selected material is: the selected pore volume is 0.503 cm 3 / g activated carbon fiber, monoalcohol (C 1 -C 6 ), low-carbon polyol series (C 1 -C 10 ), acetylacetone, glacial acetic acid, deionized water, inert gas (common), etc.

[0038] The specific steps are:

[0039] (1) Select a commercially available pore volume of 0.503 cm 3 / g of activated carbon fiber material, boiled in boiling water (deionized water) for 3 h, and ultrasonically treated for 60 min;

[0040](2) At room temperature, in a 250 mL three-neck flask equipped with a magnetic stirrer, activated carbon fiber, and a dropping funnel, add 20 mL tetrabutyl titanate dissolved in 40 mL absolute ethanol, and add 10 mL dropwise under magnetic stirring. mL acetylacetone and 15 mL glacial acetic acid, then add a mixture of 80 mL absolute alcohol solution and 15 mL water.

[0041] (3) Ultrasonic oscillation for 2 h after the addition was completed, and then stand still for 48 h.

[0042] (4) Weigh 15 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com