Beneficiation method for flotation and recovery of molybdenum from easy-floating gangue refractory molybdenum ore

A beneficiation method and gangue technology, applied in the field of flotation recovery of molybdenum beneficiation, can solve the problems of long desliming process, complex process, large equipment investment, etc., so as to relieve tension, simple process and total recovery rate. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

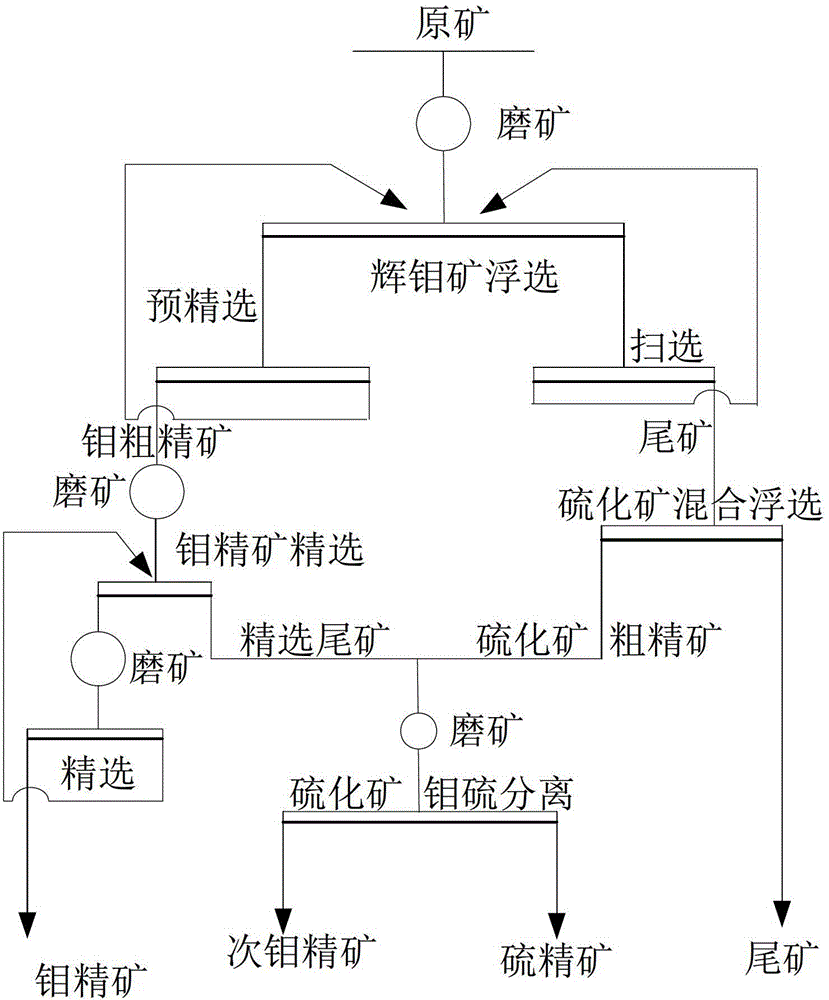

[0028] a kind of like figure 1Shown the mineral processing method of flotation recovery molybdenum from the easy floating gangue class refractory molybdenum ore of the present invention, comprises the following steps:

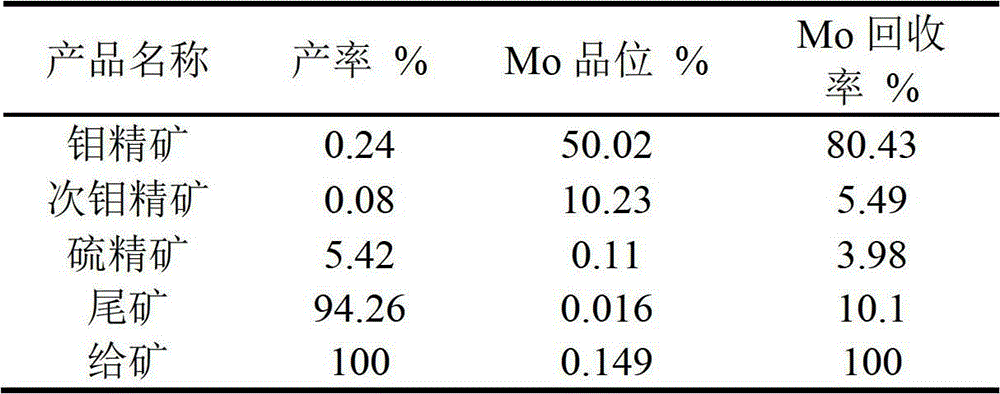

[0029] (1) Grinding: The ore feed material is a talc-type fine-grained molybdenum ore in Henan, containing 0.149% Mo, of which the oxidation rate of molybdenum is 14.67%, and the content of magnesium-containing gangue such as talc is 18%; the raw material is further ground, The grinding fineness meets -0.074mm to reach 83.3%, and the monomer dissociation degree is 84.3%;

[0030] (2) Molybdenite flotation: Flotation of the ore after step (1) is carried out by using mixed reagents including regulators, combined inhibitors, non-polar collectors and foaming agents. The specific operation process For: add regulator sodium sulfide 200g / t, add heavy metal salt copper sulfate 400g / t, adjust the stirring speed to a linear speed of 10.5m / s, stir rapidly for 15min, then...

Embodiment 2

[0038] A kind of beneficiation method of processing reclaiming molybdenum from the fine-grained refractory molybdenum ore flotation of easy buoyant gangue such as high talc of the present invention, comprises the following steps:

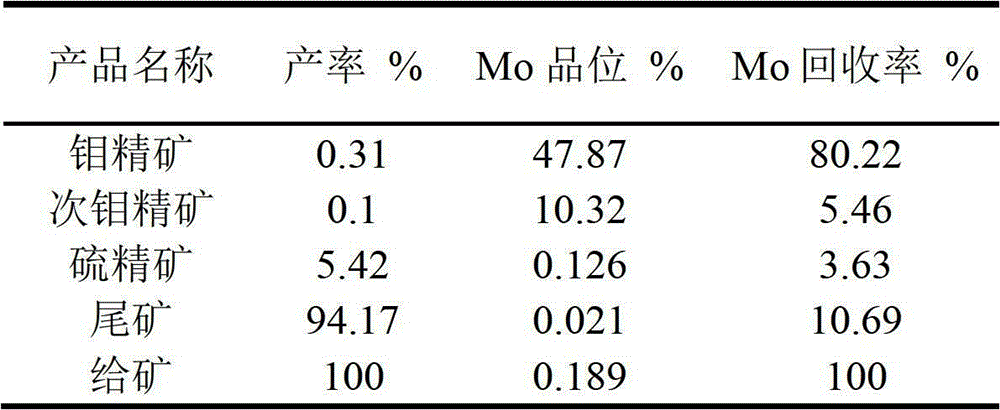

[0039] (1) Grinding: The ore feed material is a talc-type fine-grained molybdenum ore in Henan, containing 0.189% Mo, of which the oxidation rate of molybdenum is 17.35%, and the content of magnesium-containing gangue such as talc is 22%; the raw material is further ground, Grinding fineness meets -0.074mm to reach 88.50%, and the monomer dissociation degree reaches 85%;

[0040] (2) Molybdenite flotation: Flotation of the ore after step (1) is carried out by using mixed reagents including regulators, combined inhibitors, non-polar collectors and foaming agents. The specific operation process For: add regulator sodium sulfide 600g / t, add heavy metal salt zinc sulfate 1000g / t, adjust the stirring speed to a line speed of 12m / s, stir rapidly for 25min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com