Tungsten-base tungsten trioxide nano film, and preparation method and application thereof

A technology of tungsten trioxide and nano-film materials, applied in the field of nano-materials, can solve the problems affecting the photoelectric catalytic performance, electrochemical performance and sensing performance of materials, peeling of films and conductive glass substrates, and easy charge recombination, etc. The effect of mechanical stability and service life, good electron transport performance and sensing performance, and easy regulation of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

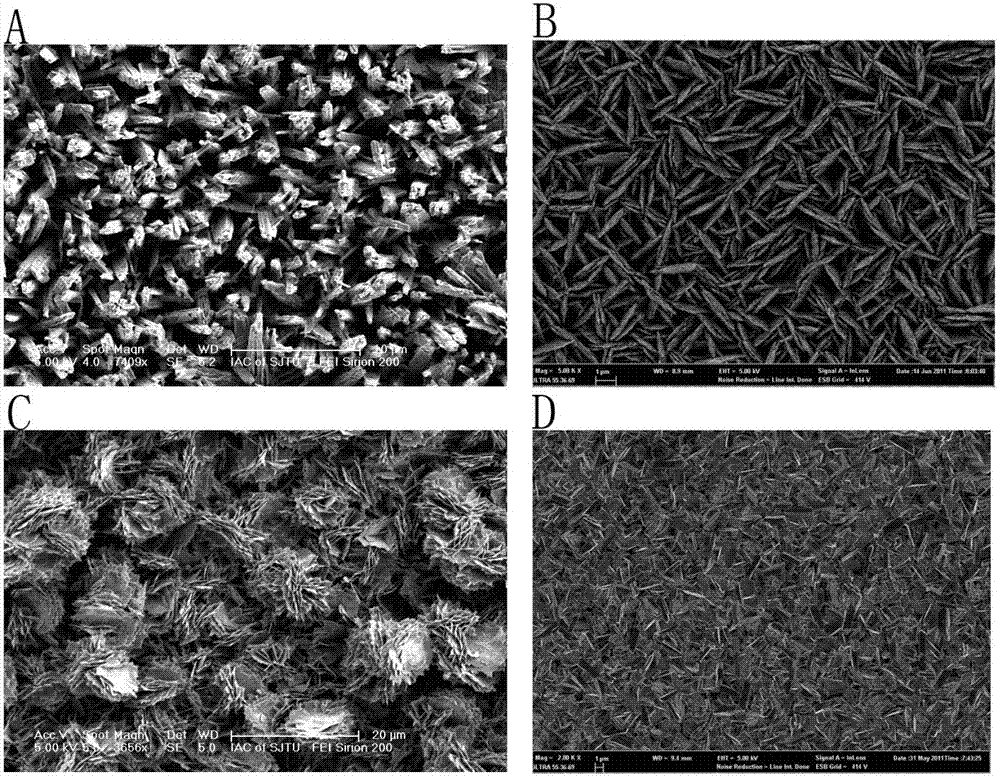

[0020] The preparation method of the tungsten-based tungsten trioxide nano-film material is as follows: after drying the polished and cleaned tungsten sheet, put it into a muffle furnace, control the temperature at 450-650° C. for 30 minutes, and form a layer on the surface of the metal tungsten. WO 3 The fine particles act as seeds for subsequent crystal growth; will be attached with WO 3 The tungsten sheet of the seed crystal is immersed in a hydrothermal reaction system, which contains polyethylene glycol with a volume fraction of 5-15% and a molecular weight of 200-400 as a crystal growth directing agent and tungsten with a concentration of 0.01-0.03mol / L Sodium acid solution is used as the material for crystal growth, and the inner wall of the reaction vessel is made of polytetrafluoroethylene material. The pH value of the reaction solution is adjusted to 1.0~2.0 with hydrochloric acid, the reaction temperature is controlled at 160~200°C, and the reaction time is 2-8h. D...

Embodiment 1

[0024] After the polished and cleaned tungsten sheet is dried, put it into a muffle furnace, control the temperature at 550°C for 30 minutes, and form a layer of WO on the surface of the metal tungsten. 3 The fine particles act as seeds for subsequent crystal growth; will be attached with WO 3The tungsten sheet of the seed crystal is immersed in a hydrothermal chemical reaction system. The hydrothermal reaction system contains polyethylene glycol with a volume fraction of 10% and a molecular weight of 300 as a crystal growth guiding agent and a sodium tungstate solution with a concentration of 0.02mol / L as a crystal growth agent. The inner wall of the reaction vessel is made of polytetrafluoroethylene material. Adjust the pH value of the reaction solution to 2.0 with hydrochloric acid, control the hydrothermal reaction temperature to 180°C, and the reaction time is 6 hours to complete the directional growth of tungsten trioxide on the surface of the tungsten substrate. ;Take o...

Embodiment 2

[0026] After the polished and cleaned tungsten sheet is dried, put it into a muffle furnace, control the temperature at 550°C for 30 minutes, and form a layer of WO on the surface of the metal tungsten. 3 The fine particles act as seeds for subsequent crystal growth; will be attached with WO 3 The tungsten sheet of the seed crystal is immersed in a hydrothermal chemical reaction system. The hydrothermal reaction system contains polyethylene glycol with a volume fraction of 10% and a molecular weight of 300 as a crystal growth guiding agent and a sodium tungstate solution with a concentration of 0.03mol / L as a crystal growth agent. The inner wall of the reaction vessel is made of polytetrafluoroethylene material. Adjust the pH value of the reaction solution to 2.0 with hydrochloric acid, control the hydrothermal reaction temperature to 180°C, and the reaction time is 2 hours to complete the directional growth of tungsten trioxide on the surface of the tungsten substrate. ;Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com